Single-Shaft Shredder

The motor of the single-shaft shredder drives the medium-speed ratio reducer through the V-belt, which in turn drives the knife shaft to rotate. The knife particles on the knife shaft tear the material during the rotation process and then form shear with the fixed knife. This part of the material is brought into the abdomen by the passive knife. When the size is smaller than the belly screen, it will fall out of the screen; otherwise, it will be brought into the crushing chamber to continue to tear and shear. The unique crushing method of the single-shaft crusher enables it to adapt to larger pieces of material and even material compression. Because its speed is medium and low, it has a large torque and high efficiency. The screen can control the discharge size well. These advantages make it widely used, and it often appears in various solid waste resource treatment projects.

Waste Processing Range

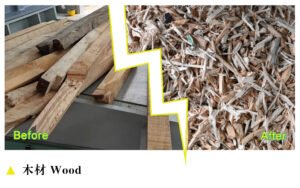

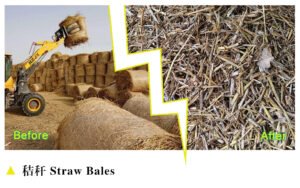

Crushing Effect Diagram

Application Scope:

- Plastics: waste materials such as plastic, rubber heads and machine heads; plastic products such as plastic sheets, pipes, films, pallets, home appliance shells, beverage bottles, woven bags, etc.

- Wood: waste wood, wood scraps, wooden molds, wooden pallets, wooden doors, wooden tables and chairs, etc.

- Plants: various straws, bamboo, tree branches, flowers, plants etc.

- Paper: document paper, wrapping paper, cardboard, books, paper pallets, etc.

- Cloth: leather scraps, chemical fiber cloth, cotton cloth, textile materials, carpets, clothes, curtains, etc.

- Metals: aluminum chips, aluminum cans, aluminum profiles, etc.

- Others: circuit boards, wires, cables, industrial scraps and mixed waste materials, color steel tiles, sponges, foams, latex, counterfeits, defective products, expired items, etc.

Equipment features

- High economy: The moving knife is of high hardness and wear resistance, and the angle can be changed for multiple uses.

- Good stability: The unique liquid and slag channels protect the hydraulic system from interference.

- High safety: The fixed knife can not only be adjusted but also locked, effectively preventing the knife from collision.

GIGAPA—Creating unlimited possibilities together, the company is mainly engaged in the research and development, production, and sales of hydraulic equipment, environmental protection equipment, renewable resource processing equipment, solid waste resource equipment, customized hydraulic cylinders, customized hydraulic stations, and other products. Based in China, serving the world, technological innovation, and intelligent manufacturing upgrades—we have been working hard and creating continuously!

E-mail: info@gigapa.com

Tel:+86-18019665417

Add: Zhihui Valley, Rugao, Nantong, Jiangsu Province, China

-200x45.png)