In the ever-evolving world of industrial waste management, efficiency and reliability are paramount. One of the most versatile machines for tackling solid waste processing challenges is the GIGAPA Single Shaft Shredder. Designed to deliver consistent and high-quality results across a wide range of materials, this shredder is fast becoming the go-to choice for businesses seeking to enhance their recycling capabilities. Whether it’s plastics, metals, or textiles, the single shaft shredder provides a highly efficient solution to improve waste processing while maintaining safety and cost-effectiveness.

How the Single Shaft Shredder Works

At its core, the single shaft shredder uses a sophisticated shredding mechanism to break down a wide variety of materials. The motor drives a medium-ratio gear reducer via V-belts, which rotates the cutter shaft. Mounted on this shaft are high-strength rotating blades that tear through materials, creating a shearing action against stationary blades. This unique design enables the machine to shred even large lump materials or compressed bales, which would otherwise be difficult to process.

As materials are shredded, the particles are carried into a chamber where they continue to be processed. Once the particles are smaller than the size of the screen mesh, they fall through into the collection area. Larger particles are recirculated for further shredding. The combination of the rotating and stationary blades, along with the screen mesh, ensures consistent particle sizes and high throughput.

What sets this shredder apart is its ability to operate at a medium-low speed, which results in high torque while minimizing energy consumption. This feature is particularly important for businesses that need to process tough materials without sacrificing efficiency. Furthermore, the shredder is equipped with a highly effective screen mesh that controls the output particle size, making it ideal for specific processing requirements in recycling operations.

Wide Applicability in Various Industries

The single shaft shredder excels in a variety of applications across different industries. Its flexibility makes it an indispensable tool for companies involved in recycling and waste management. Below are some of the key industries and materials that benefit from this shredder:

1. Plastic Recycling:

The single shaft plastic shredder is perfect for processing a broad range of plastic products, including plastic sheets, pipes, films, pallets, and household appliance shells. It also efficiently handles plastic beverage bottles, woven bags, and other plastic materials. Recycling plastic with the single shaft plastic shredder helps reduce waste, save resources, and improve the efficiency of plastic recycling plants.

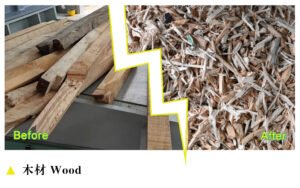

2. Wood Processing:

Wood waste, including wood scraps, wooden molds, pallets, and even wooden furniture like doors, tables, and chairs, can be easily shredded with the single shaft shredder. The machine is capable of handling large wooden pieces, making it ideal for woodworking industries that generate substantial amounts of wood waste. The shredded wood can be used for various purposes, such as mulch or biofuel, or recycled into new products.

3. Paper Shredding:

From office paper and wrapping paper to cardboard, books, and paper trays, the Single Shaft Shredder efficiently processes a wide range of paper materials. Paper recycling is essential for reducing environmental impact, and the shredder ensures that businesses can handle large volumes of paper waste with minimal effort.

4. Fabric and Leather:

Whether it’s leather scraps, synthetic fiber cloth, cotton cloth, or textile materials like carpets, clothes, and curtains, this shredder provides excellent shredding capabilities for fabric and leather waste. Textile waste is a growing concern globally, and recycling it efficiently reduces landfill waste while creating raw materials for the textile industry.

5. Metal Shredding:

Aluminum scraps, cans, and profiles can be processed effectively by the GIGAPA shredder. The ability to shred metal materials allows businesses to reclaim valuable metals that can be reused in manufacturing, helping companies achieve greater material recovery rates and reduce the environmental impact of mining new metals.

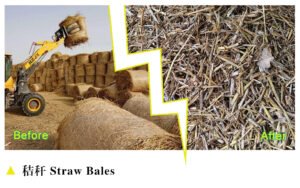

6. Other Materials:

The single shaft shredder is also highly effective for shredding a variety of other materials, such as colored steel tiles, sponges, foam, latex, expired goods, and substandard products. The machine’s versatility ensures that it can handle a wide range of waste types, making it a reliable choice for businesses that deal with diverse materials.

Technical Highlights

1. High Cost-Effectiveness:

One of the standout features of the GIGAPA Single Shaft Shredder is its high cost-effectiveness. The machine is built to last, with high-hardness, wear-resistant blades that can be reused multiple times. The only maintenance required is replacing the angle of the blades, which extends the life of the shredder and minimizes operational costs. This makes it an excellent investment for businesses looking to maximize their return on investment.

2. Exceptional Stability:

The single shaft shredder is designed with unique liquid and debris channels, which ensure that the hydraulic system is protected from any interference caused by waste materials. This improves the machine’s stability, reducing the likelihood of breakdowns and ensuring continuous, uninterrupted operation.

3. Safety Features:

Safety is always a priority in industrial operations, and the single shaft shredder incorporates several safety features to protect both the machine and operators. The fixed knives on the shredder can not only be adjusted to suit different materials but can also be locked in place to prevent accidental collisions with other blades. This reduces the risk of operational accidents and enhances workplace safety.

Effect Comparison:

Why Choose the GIGAPA Single Shaft Shredder?

For businesses focused on waste reduction, resource recovery, and efficient recycling, the single shaft plastic shredder offers a reliable and cost-effective solution. Its robust design, high efficiency, and versatility across a broad range of materials make it an invaluable asset for companies involved in recycling, manufacturing, and waste management.

By investing in the single shaft shredder, businesses can not only improve their waste processing efficiency but also contribute to environmental sustainability by ensuring that valuable materials are recycled and reused rather than ending up in landfills. The shredder’s advanced features and reliable performance make it the ideal choice for companies looking to stay ahead in an increasingly eco-conscious market.

-200x45.png)