In modern livestock farming, animal welfare and operational efficiency are top priorities. According to the FAO, poor bedding contributes to up to 25% of preventable animal illnesses, including respiratory and hoof problems. High-quality wood shavings, known for their absorbency and comfort, can absorb 2.5× their weight in moisture and improve feed conversion by up to 10% in poultry farms.

To meet this need, more farms are investing in wood shaving machines, which turn raw wood into clean, uniform bedding — reducing costs, improving hygiene, and supporting sustainable operations.

What Is a Wood Shaving Machine?

A wood shaving machine, also known as a wood shaver, is specialized equipment designed to produce thin, uniform wood shavings for use in animal bedding. These machines are widely used in poultry houses, cattle farms, horse stables, and pet breeding facilities due to their ability to create soft, absorbent, and hygienic bedding material from raw wood.

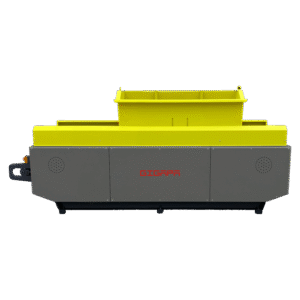

GIGAPA’s wood shaving machine is engineered for efficiency, consistency, and high throughput. It features:

- High linear-speed blades that rapidly plane the wood surface, producing thin, curly shavings with excellent softness and moisture absorption.

- A chain-driven feed system that moves wood blocks or logs back and forth relative to the cutter shaft. This ensures all surfaces are evenly shaved, increasing material utilization and producing shavings of consistent size and thickness.

- A bottom-mounted conveyor system that discharges finished shavings quickly and efficiently, streamlining the production process and reducing manual handling.

This intelligent design allows for stable performance, customizable shaving thickness, and continuous operation. Depending on the model, the machine can process various types of wood, including softwood, hardwood, and even leftover wood scraps, turning them into premium bedding material.

With output capacity reaching up to 1–3 tons per hour, our wood shaving machine not only reduces operating costs but also enables farms to produce their own high-quality bedding on demand — improving animal welfare, hygiene, and farm sustainability.

What Shapes of Shavings Can Wood Shaving Machine Produce?

A wood shaving machine can usually produce the following common shapes of shavings according to the blade structure, feeding method and wood characteristics. Each shape is suitable for different purposes, especially in animal bedding.

- Thin Flake Shavings

- Features: wide, thin and soft, with a shape close to natural shavings.

- Advantages: good softness, suitable for large animals such as horses and cattle; good elasticity and air permeability.

- Applicable scenarios: stables, dairy cow sheds, pet bedding.

- Curly or Spiral Shavings

- Features: After the blade cuts at high speed, the sawdust automatically curls up in a spiral or wavy shape.

- Advantages: neat appearance, high looseness, helps keep the bedding dry, and beautiful bagging.

- Applicable scenarios: packaging filling materials, high-end pet bedding, and display bedding.

- Strip-type Shavings

- Features: longer and straighter strip-shaped sawdust with uniform thickness.

- Advantages: strong water absorption capacity, stable structure, and suitable for areas with a large laying area and frequent replacement.

- Applicable scenarios: chicken coops, duck houses, and large-scale breeding bedding.

- Chunky or Coarse Shavings

- Features: large sawdust size, thick thickness, and certain hardness.

- Advantages: long service life, suitable for places with high pressure resistance requirements, and not easy to harden.

- Applicable scenarios: large animal pens, bottom bedding.

GIGAPA’s equipment can adjust the blade speed, planing angle, or chip thickness and flexibly control the shape of wood chips according to customer needs.

Benefits of Using Wood Shaving Machine for Animal Bedding

- Excellent Moisture Absorption for a Dry Environment

Wood shavings have strong absorbent properties, which help keep stalls and cages dry by quickly soaking up urine and moisture. Studies show that high-quality wood shavings can absorb over 2.5 times their weight in liquid, reducing the risk of wet bedding-related diseases.

- Ammonia Control for Better Air Quality

By absorbing moisture, wood shavings help limit the buildup of ammonia gas, which can otherwise harm animals’ respiratory systems. Cleaner air leads to healthier livestock and fewer respiratory issues.

- Soft and Comfortable Bedding

The soft, cushion-like texture of the wood shaving machines helps protect animals from joint stress, pressure sores, and hoof problems. It promotes better rest and overall animal welfare, especially for large animals like horses and dairy cows.

- Thermal Insulation in All Seasons

Wood shavings act as a natural thermal insulator, keeping animals warm in winter and cool in summer. This contributes to a more stable and comfortable environment year-round.

- Lower Cleaning and Maintenance Costs

Thanks to their moisture control and anti-caking properties, wood shavings stay fresh longer and are easy to clean and replace, saving time and labor on daily barn maintenance.

- Eco-Friendly and Cost-Effective

Made from sawmill byproducts or recycled wood, wood shavings are a sustainable and affordable bedding option. After use, they can be composted or turned into organic fertilizer, reducing environmental impact.

Applications of Wood Shaving Machines

In addition to animal husbandry, what other industries can use wood shaving machine?

- Pet Bedding Industry

Widely used by pet stores, pet boarding centers, and cat litter manufacturers, wood shavings provide dust-free, odorless, and eco-friendly bedding ideal for small pets such as hamsters, rabbits, and guinea pigs.

- Gardening and Landscaping

Wood shavings serve as mulch material that helps suppress weeds, retain soil moisture, and enhance garden aesthetics. They also act as insulation around plant roots, promoting healthier plant growth.

- Industrial Packaging

Due to their softness and cushioning properties, wood shavings are used as protective packaging material for fragile items like machinery, ceramics, and glass during transportation, reducing damage risks.

- Furniture Filling and Board Manufacturing

Wood shavings are raw materials in producing particleboards, fiberboards, and composite panels. They can also be used as filler material in furniture production, such as sofas, cushions, and mattresses.

Advantages of GIGAPA Wood Shavings

- Strong adaptability

The thickness of the wood shavings can be adjusted, and the size of the wood shavings can be changed as needed.

- Rapid economic growth

The blades are hard and wear-resistant and can be reused many times by grinding or changing the angle.

- Easy operation

The high degree of automation makes the operation simple and convenient.

A wood shaving machine isn’t just another piece of equipment—it’s a long-term solution that pays for itself in cost savings, healthier livestock, and higher productivity. By producing clean, consistent, and high-quality bedding on demand, farmers gain full control over their animals’ living conditions while reducing reliance on expensive commercial alternatives.

Whether you run a poultry farm, dairy operation, or swine facility, investing in a wood shaving machine ensures better hygiene, lower disease risks, and improved overall farm performance. In the end, it’s not just about saving money—it’s about creating a safer, more sustainable future for your animals and your business.

If you’re looking for a reliable China wood shaving machine factory, contact GIGAPA today to discover how our advanced machines can transform your farm’s bedding solutions.

-200x45.png)