Every year, the mountains of straw make everyone worried? Don’t burn them and pollute the environment! A straw shredder can easily solve the problem of straw disposal and turn waste straw into a “hot commodity”! Today, let’s take a look at how powerful this “waste-to-treasure” artifact is!

1. Straw shredder: “shaping expert” for agricultural waste

What is a straw shredder?

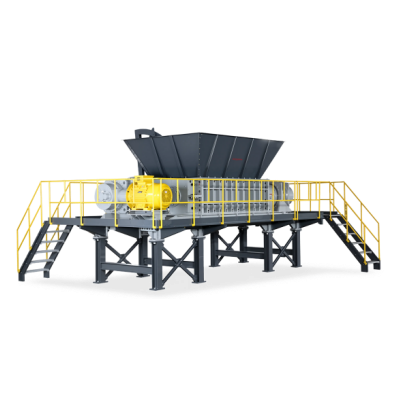

A straw shredder is a mechanical device specially used to process various types of crop straw. It cuts and crushes the straw into small segments of 3-10cm through high-speed rotating blades, making it easier to use later.

Applicable straw types

- Cornstalk straw

- Wheat straw

- Rice straw

- Soybean straw

- Cotton straw, etc.

2. Five advantages of shredder processing

- High processing efficiency: 2-5 tons of straw can be processed in 1 hour, which is 20 times more efficient than manual labor!

- Wide range of uses: Crushed straw can be used for feed, fuel, fertilizer, and other purposes

- Space saving: The volume is reduced by 3-5 times, making it easier to stack and transport

- Environmental protection and energy saving: Replace incineration and reduce air pollution

- Increase income: The value of processed straw doubles and can be easily converted into cash

3. Six uses of crushed straw

High-quality feed

The crushed straw is easier to ferment and is an ideal roughage for livestock such as cattle and sheep.

Biomass fuel

It can be compressed into pellets with a calorific value of 3500-4000 kcal/kg.

Organic fertilizer

It accelerates the decomposition process and is a high-quality raw material for making compost.

Cultivation substrate

Used for the cultivation of crops such as mushrooms and vegetables.

Papermaking raw materials

Supplying paper mills can make a profit of 200-400 yuan per ton.

Environmentally friendly building materials

After processing, it can be used to make fiberboard, sound insulation materials, etc.

4. A complete guide to shredder operation

Preliminary preparation

- Clean out stones, metals, and other debris from the straw

- Dry it in the sun until the moisture content is below 30% (wet straw can also be processed, but the efficiency is slightly lower)

Equipment commissioning

- Adjust the blade gap according to the type of straw (large for corn stalks and small for wheat stalks)

- Check whether the lubricating oil is sufficient

Operation process

- Start the machine and run it idle for 30 seconds to confirm normal operation

- Evenly feed the straw to avoid excessive blockage

- Observe the particle size of the output and adjust the speed if necessary

- After the operation is completed, run it idle for 1 minute to clean up the residual material

Maintenance

- Add lubricating oil every 8 hours of work

- Check the blade wear regularly

- Clean up the residual material inside the machine after the operation

The straw shredder not only solves the environmental problem but also opens up a new channel for increasing income! Whether it is for personal use or business operation, it is a good investment that is sure to make money!

-200x45.png)