Introduction

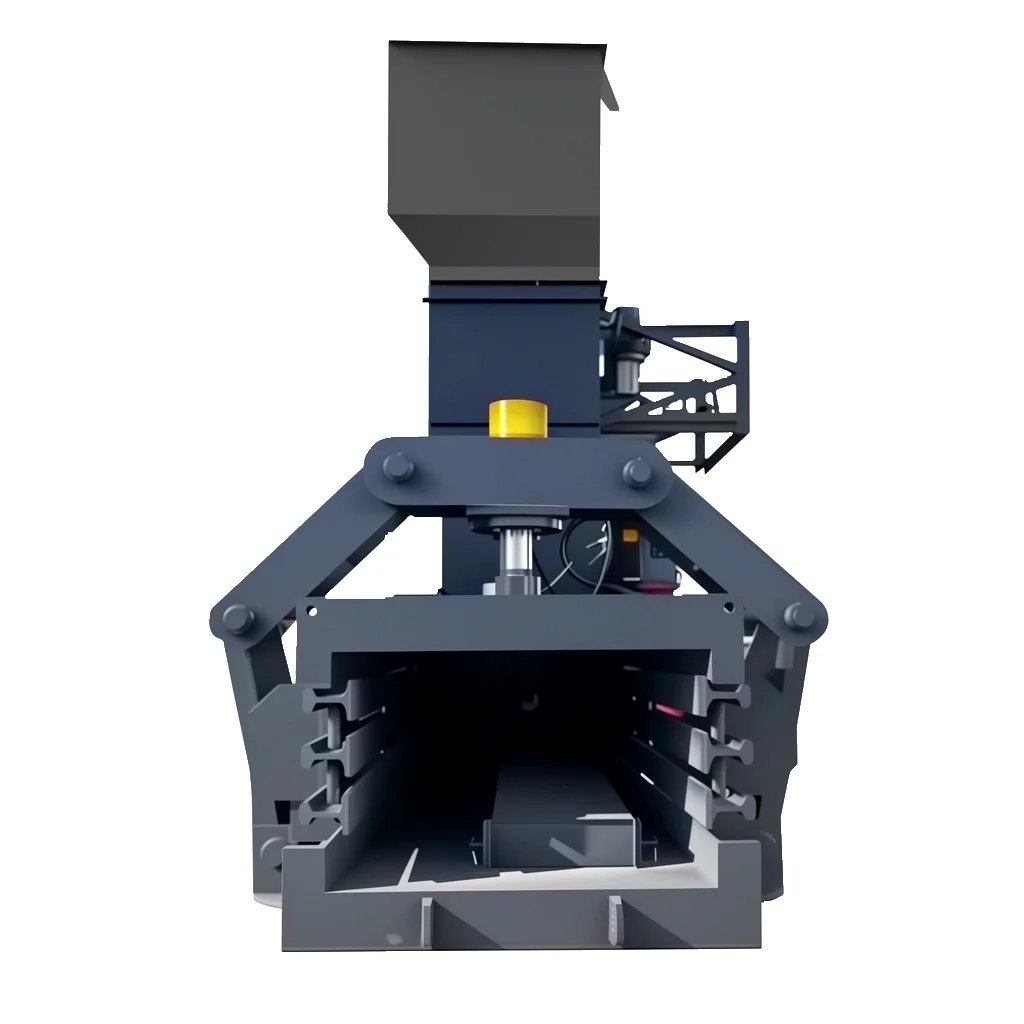

The industrial hydraulic press baler is a high-performance, heavy-duty machine designed for the efficient compression and baling of various materials, including cardboard, plastic, metal, and paper waste. This machine is widely used in recycling centers, warehouses, scrap yards, and industrial plants. It ensures space optimization, cost reduction, and environmental sustainability by compacting large volumes of waste into manageable bales, which can then be easily stored, transported, or recycled.

With its advanced hydraulic technology, the industrial waste press baler offers powerful performance, reliability, and versatility for a wide range of industries. It is an essential tool for businesses aiming to streamline their waste management processes and contribute to a more sustainable and cost-efficient operation.

Key Features of the Industrial Hydraulic Press Baler

-

High-Pressure Hydraulic System

The core feature of the industrial waste press baler is its hydraulic press system, which uses high-pressure mechanisms to compress materials tightly. This results in high-density bales that are easy to store and transport. The hydraulic system provides consistent performance, making it suitable for continuous, heavy-duty operations. -

Versatility in Material Handling

This machine is capable of handling a variety of materials, including cardboard, paper, plastic, textiles, aluminum cans, and more. Its adaptability makes it an invaluable asset for industries ranging from waste recycling to manufacturing, where efficient waste management is critical. -

Fully Automatic Operation

The industrial hydraulic press baler is equipped with advanced automatic features that reduce the need for manual intervention. With fully automatic operations, the baler can efficiently feed, compress, and discharge waste materials with minimal operator input, thereby improving efficiency and reducing labor costs. -

High Bale Density

The machine is designed to produce high-density bales, which helps save valuable storage space and reduces transportation costs. The dense bales are easier to handle and can be stacked securely, further optimizing space utilization in your facility. -

Durable and Reliable Design

Built with high-quality materials, the industrial hydraulic press baler is designed for long-lasting performance. The robust construction ensures that the machine can withstand the rigors of daily use in demanding environments, providing businesses with a dependable solution for their waste management needs. -

Safety Features

The machine is designed with multiple safety features to ensure operator protection and minimize the risk of accidents. These features include emergency stop buttons, automatic shutoff, and safety guards, making it a safe machine to operate in industrial settings. -

User-Friendly Controls

The baler is equipped with an intuitive control panel, making it easy for operators to monitor and adjust settings. Even for users with minimal training, the machine can be operated efficiently, reducing the risk of errors and improving overall productivity.

Applications of the Industrial Waste Press Baler

The industrial hydraulic press baler is a highly versatile machine, suitable for a wide variety of applications. Some of the key industries and sectors that benefit from this technology include:

-

Waste Recycling

Recycling centers use the industrial waste press baler to efficiently process large volumes of recyclable materials. By compressing materials such as cardboard, plastic, and paper, the baler reduces waste volume and makes it easier to transport and recycle. -

Scrap Metal Processing

Scrap yards and metal processing facilities use this baler to compact metal waste, including aluminum cans and steel scraps, into dense bales. These bales are then easier to handle and can be sold as scrap metal for recycling or repurposed in manufacturing processes. -

Retail and Manufacturing

Retail businesses and manufacturing plants that generate a high amount of packaging waste can benefit from the industrial hydraulic press baler. It helps compact cardboard boxes, plastic packaging, and other materials, reducing waste disposal costs and improving operational efficiency. -

Textile Industry

In textile manufacturing, the baler is used to compress textile waste such as fabric scraps and fibers. The compacted bales are easier to store, manage, and recycle, contributing to waste reduction and sustainability in the textile industry. -

Paper and Cardboard Waste Management

Businesses in the paper and cardboard industries use hydraulic press balers to reduce the volume of waste generated by packaging materials. The high-density bales produced by the baler make it easier to transport and recycle paper and cardboard, reducing landfill usage and contributing to the circular economy.

How the Industrial Hydraulic Press Baler Works

The industrial hydraulic press baler operates through a simple yet efficient process that maximizes the compression of waste materials. Here’s a basic overview of how it works:

-

Feeding the Material

Waste materials are loaded into the hopper, from where they are fed into the compression chamber. The machine is designed with an automatic feeding system, allowing materials to be processed continuously without manual intervention. -

Compression

Once inside the compression chamber, the materials are pressed by hydraulic pistons. The high pressure forces the materials to compact tightly, forming high-density bales. The hydraulic system ensures consistent and powerful compression, even for difficult-to-compress materials like scrap metal. -

Bale Ejection

Once the materials are compacted, the formed bale is ejected automatically through the discharge chute. Depending on the design, the bales can be ejected either horizontally or vertically, making it easier to stack and store them. -

Cutting and Tying

The baler may include an automatic tying system, which wraps the bale with wire or string to secure it in place. This ensures the bale holds its shape during storage and transportation.

Benefits of Using an Industrial Hydraulic Press Baler

-

Cost Savings

By reducing the volume of waste materials, the industrial waste press baler lowers waste disposal and transportation costs. The high-density bales are easier to handle and require less space, reducing storage costs as well. -

Environmental Impact

The baler promotes environmental sustainability by aiding in the recycling process. The machine helps divert waste from landfills, making it an essential tool for businesses aiming to minimize their environmental footprint. -

Increased Efficiency

With automated features and high-speed operation, the industrial hydraulic press baler improves productivity and efficiency in waste management processes. The machine reduces the need for manual labor, saving time and resources. -

Space Optimization

The compact bales produced by the baler make better use of available storage space. This is especially important for businesses with limited storage areas, as it allows them to store larger quantities of waste materials in a more organized and manageable way.

Conclusion

The industrial hydraulic press baler is an essential piece of equipment for businesses in industries such as recycling, scrap metal processing, and manufacturing. Its powerful hydraulic system, versatility, and automated features make it a highly efficient solution for compressing and managing waste materials. By investing in this machine, businesses can reduce waste disposal costs, enhance recycling efforts, and contribute to a more sustainable environment. With its durable design and easy operation, the industrial hydraulic press baler is a smart and cost-effective choice for improving waste management operations.

-200x45.png)