In the maritime industry, effective waste management is more than just a legal requirement—it is a crucial part of maintaining environmental sustainability and operational efficiency. One piece of equipment that is increasingly being recognized as indispensable is the marine garbage baler. Designed for ships, offshore platforms, and other marine applications, this specialized machine compresses various types of onboard waste into compact bales, making storage, transportation, and disposal far easier.

Whether you operate a cargo vessel, fishing boat, cruise liner, or offshore oil rig, investing in a high-quality marine garbage baler can significantly reduce operational costs, improve onboard hygiene, and help you comply with international waste disposal regulations.

What is a Marine Garbage Baler?

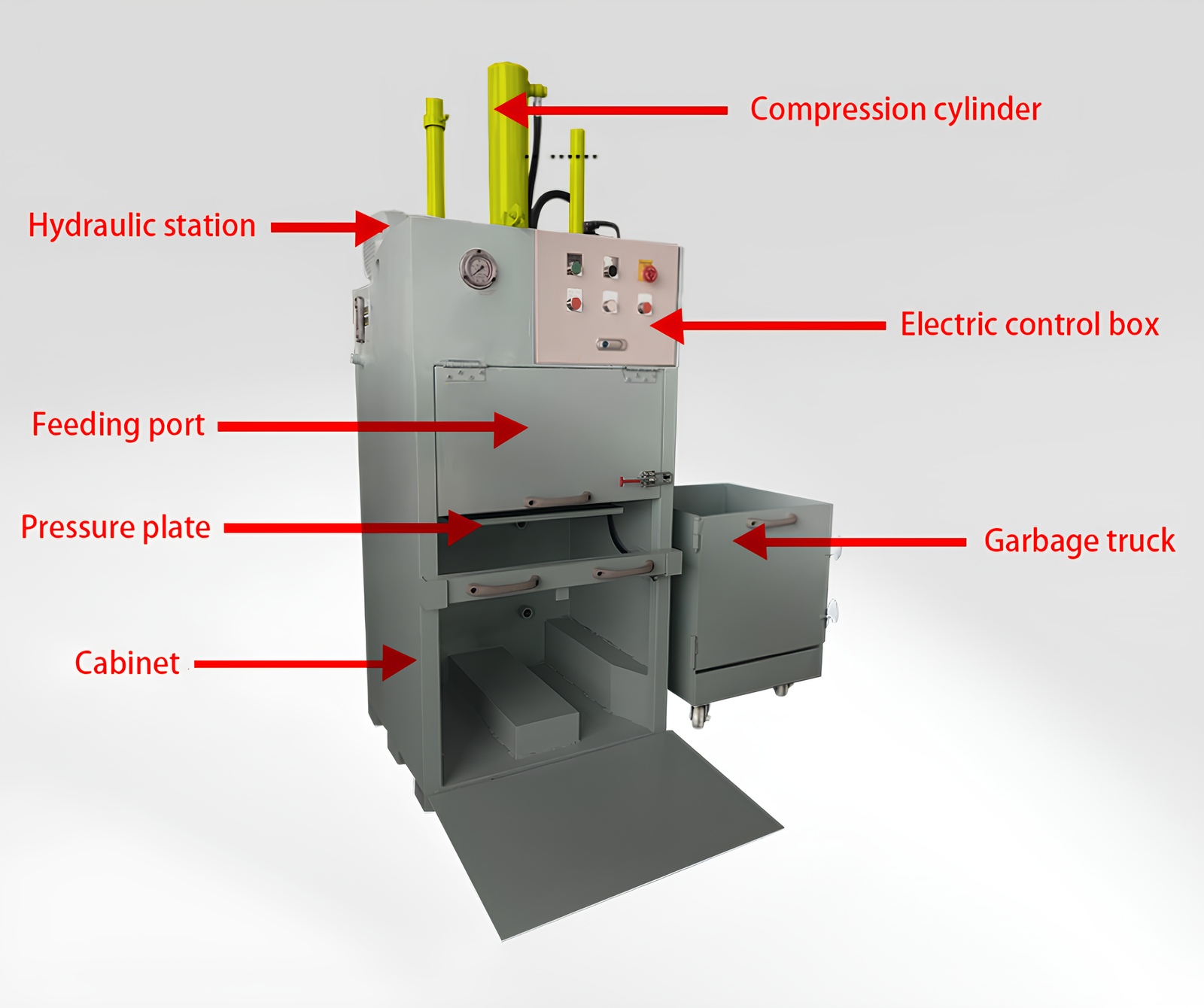

A marine garbage baler is a hydraulic compaction machine specifically designed for marine environments. It compresses ship-generated waste—such as plastic bottles, cardboard, fishing nets, and aluminum cans—into dense, stackable bales. Unlike land-based balers, marine balers are built to withstand harsh conditions such as salty air, constant movement, and limited onboard space.

Most marine garbage balers feature corrosion-resistant steel structures, safety locking systems, and compact designs to fit into small engine rooms or waste management areas on board.

Why Offshore Platforms and Vessels Need a Marine Garbage Baler

1. Space-Saving Efficiency

Waste accumulation can quickly overwhelm the limited space available on ships and offshore platforms. By compressing waste to a fraction of its original volume, a marine garbage baler allows for more efficient storage and reduces the frequency of waste transfers to shore facilities.

2. Compliance with Environmental Regulations

The International Maritime Organization (IMO) mandates strict guidelines for marine waste disposal. A marine garbage baler helps vessel operators comply with MARPOL Annex V, ensuring that waste is stored, recorded, and disposed of properly at designated port facilities.

3. Improved Hygiene and Safety

Loose garbage attracts pests, emits unpleasant odors, and poses potential health risks to crew members. By baling waste in sealed, manageable packages, you keep work areas cleaner and safer.

4. Reduced Waste Disposal Costs

Compact bales require less storage space and fewer waste-handling trips. Over time, this can lead to significant cost savings in waste transportation and disposal fees at port facilities.

Applications of Marine Garbage Balers

Marine garbage balers are highly versatile and can be used in various maritime sectors:

- Cargo Ships: Manage packaging waste, dunnage, and crew-generated garbage.

- Fishing Vessels: Compact used nets, ropes, and plastic debris collected at sea.

- Cruise Ships: Handle large volumes of food packaging, cardboard, and recyclables from passengers.

- Offshore Oil Rigs: Maintain cleanliness and safety while reducing waste handling costs.

- Navy and Coast Guard Ships: Ensure compliance with environmental regulations during long missions.

Key Features to Look for in a Marine Garbage Baler

When choosing a marine garbage baler for offshore platforms or vessels, several factors can make a significant difference:

1. Corrosion-Resistant Materials

The baler should be made from stainless steel or treated steel to withstand saltwater exposure.

2. Compact and Space-Efficient Design

Limited space onboard requires a machine with a small footprint without sacrificing compaction power.

3. Hydraulic Power System

A reliable hydraulic system ensures consistent compression force and efficient operation.

4. Safety Features

Interlock doors, emergency stop buttons, and overload protection are essential for safe use in marine environments.

5. Ease of Maintenance

Accessible components and simple maintenance procedures ensure minimal downtime.

6. Power Options

Consider whether the baler will run on the vessel’s main power supply or require its own generator.

How a Marine Garbage Baler Works

The process is simple but highly effective:

- Loading – Waste is placed into the baler’s chamber.

- Compaction – The hydraulic ram compresses the waste into a dense block.

- Baling – The bale is tied with durable straps or wires to maintain its shape.

- Storage – The compact bales are stored safely until they can be offloaded at a port or waste processing facility.

This streamlined process allows ships and offshore facilities to handle large volumes of waste with minimal effort.

Benefits of Using a Marine Garbage Baler for Offshore Platforms

-

Enhanced Environmental Stewardship

By preventing loose waste from entering the sea, a marine garbage baler contributes directly to ocean conservation. -

Optimized Waste Logistics

The reduced volume of baled waste means fewer waste runs, saving fuel and operational time. -

Cost Efficiency

Reduced disposal fees and optimized space usage translate into long-term financial savings. -

Improved Crew Morale

Cleaner work environments contribute to higher crew satisfaction and productivity. -

Recycling Opportunities

Many baled materials, such as plastics, cardboard, and metals, can be sold to recycling companies, creating an additional revenue stream.

Choosing the Right Marine Garbage Baler for Your Vessel or Platform

When selecting a marine garbage baler, it’s important to match the machine’s capacity and design to your vessel’s waste output and space constraints. Consider:

- Waste Volume: High-volume ships may require heavy-duty, high-capacity balers.

- Material Types: Ensure the baler can handle the types of waste you produce most often.

- Installation Space: Measure the intended area and choose a baler with an appropriate footprint.

- Power Availability: Verify that the vessel’s power system can support the baler’s requirements.

- Brand Reputation: Invest in a proven, marine-grade baler from a reputable manufacturer.

Maintenance Tips for Long-Term Performance

A well-maintained marine garbage baler can last many years, even in challenging offshore environments. Here’s how to ensure longevity:

- Regular Lubrication: Keep moving parts well-oiled to prevent wear and tear.

- Corrosion Prevention: Inspect and treat any signs of rust promptly.

- Hydraulic Fluid Checks: Maintain fluid levels and replace them according to the manufacturer’s guidelines.

- Inspection of Safety Systems: Ensure all safety features are functional before each use.

- Cleaning: Remove debris from the chamber to prevent jams and maintain efficiency.

Marine Garbage Baler and Sustainability Goals

Sustainability is a growing priority in the maritime industry. Offshore platforms and vessels are under increasing pressure to reduce their environmental footprint. A marine garbage baler supports these goals by:

- Minimizing ocean pollution

- Supporting waste segregation and recycling

- Reducing carbon emissions from waste transport

- Promoting compliance with green shipping initiatives

Conclusion: A Smart Investment for Offshore Operations

For any offshore platform or vessel, a marine garbage baler is not just an optional piece of equipment—it’s a necessity for efficient waste management, cost savings, and regulatory compliance. By investing in a high-quality baler, you ensure cleaner working conditions, reduced environmental impact, and a stronger commitment to sustainable operations.

If your goal is to improve waste handling, reduce costs, and enhance your environmental credentials, now is the time to explore marine garbage baler solutions tailored to your needs. Contact a trusted supplier today and take the first step toward smarter, cleaner, and more compliant maritime waste management.

-200x45.png)