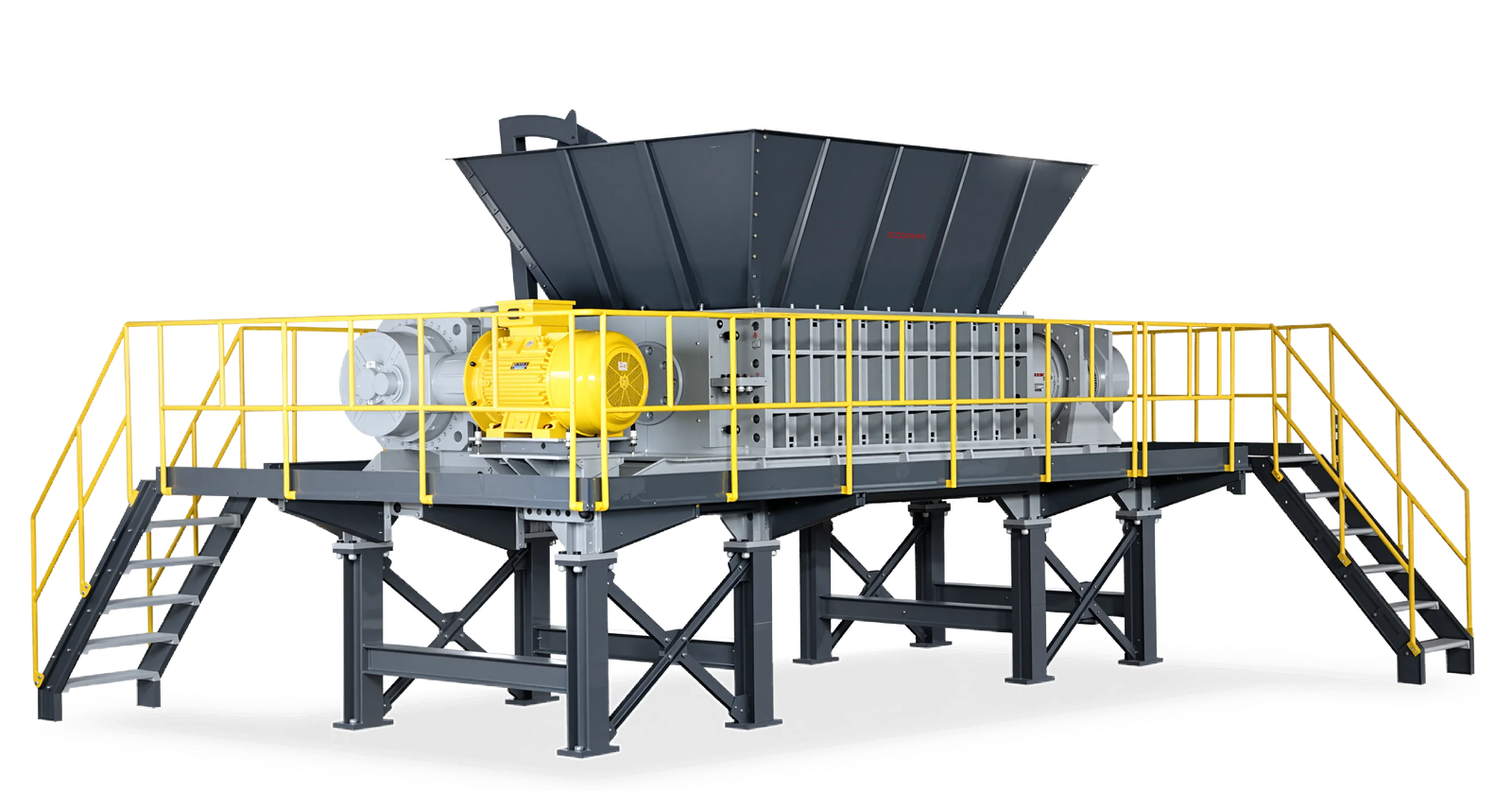

In today’s industrial and recycling landscape, the dual shaft shredder has become an indispensable piece of equipment. With its two counter-rotating shafts and heavy-duty blades, it can cut, tear, and reduce even the most difficult materials. This flexibility makes it an essential choice for scrap yards, recycling plants, waste management companies, and manufacturing industries that need to handle bulky or tough waste streams.

Unlike single-shaft machines that specialize in uniform shredding, the dual shaft shredder is known for its ability to process a wide variety of input materials without clogging or stalling. It is designed to achieve consistent particle size reduction, enhance downstream sorting, and improve overall system efficiency.

In this article, we will take a detailed look at the top 10 materials that can be effectively processed by a dual shaft shredder, as well as the unique advantages this technology brings to industrial operations.

1. Metal Scrap

One of the toughest materials handled by shredders is metal. Steel beams, aluminum sheets, copper wires, and even car body parts all require strong torque and sharp blades to break down. A dual shaft shredder is ideal for this purpose, as it can reduce metal scrap into uniform pieces suitable for smelting or further refining.

Shredding not only reduces the volume but also helps recover valuable alloys that can be reintroduced into the production cycle. For example, recycling aluminum through shredding and remelting consumes only 5% of the energy needed for virgin production.

2. Electronic Waste (E-Waste)

The global e-waste stream is growing at an unprecedented rate, exceeding 50 million tons annually. Electronics contain hazardous materials as well as valuable metals, which makes efficient dismantling crucial.

A dual shaft shredder is capable of reducing entire devices—such as laptops, smartphones, printers, and even refrigerators—into smaller fractions. After shredding, magnetic separators, eddy current systems, and optical sorters can recover metals like copper, gold, and aluminum.

Using shredding in e-waste management is like peeling layers from a digital onion: each pass reveals valuable components that would otherwise be lost. By integrating the right shredder, recyclers improve profitability while reducing environmental hazards.

3. Tires and Rubber

End-of-life tires are notoriously difficult to manage due to their durability. Simply landfilling them is wasteful and environmentally harmful. The dual shaft shredder solves this challenge by cutting rubber into manageable chips.

Shredded tire rubber can be used for tire-derived fuel (TDF), which has a higher calorific value than coal. It can also be repurposed for playground surfacing, sports fields, or road construction additives.

The GIGAPA GTS-E series, with its high torque and wear-resistant cutters, is engineered for continuous tire shredding operations, helping businesses turn waste into valuable resources.

4. Plastic Waste

Plastic waste is one of the most pressing environmental challenges of our time. From PET bottles to PVC pipes, plastics come in many forms and require reduction before recycling.

A dual shaft shredder efficiently reduces plastics into flakes or chips, which can be washed, pelletized, and reintroduced into manufacturing. For example, shredded PET bottles are used to produce new fibers, packaging, or even automotive parts.

Without shredding, these plastics often clog recycling streams. With it, they are transformed into valuable raw materials.

5. Wood and Pallets

Wood waste from construction, demolition, or logistics can take up massive space if not reduced. Shredding transforms wooden pallets, furniture, or construction beams into chips. These chips can then be used for biomass fuel, particleboard, or composting.

In many cases, a dual shaft shredder acts like a carpenter’s saw, transforming bulky wood into clean, uniform pieces that can feed into new value chains.

By adopting dual shaft shredder, companies handling large volumes of pallets or construction waste can ensure reliable reduction without constant blade wear or breakdowns.

6. Paper and Cardboard

The demand for secure and large-scale destruction of documents has grown due to data protection regulations. At the same time, the recycling of cardboard packaging has become more important in the e-commerce era.

A dual shaft shredder makes quick work of thick stacks of paper, entire cardboard bales, or rejected packaging materials. Unlike small office shredders, industrial-grade machines ensure throughput in tons per hour, not kilograms per day.

This allows recycling centers to feed shredded paper into pulping systems, where it becomes the raw material for new paper products.

7. Textile and Fabric Waste

The textile industry generates millions of tons of waste each year, ranging from off-cuts in garment factories to discarded clothing from consumers. A dual shaft shredder can reduce fabric into fibers, which can then be reused in insulation, automotive padding, or even spun into new yarns.

This is an essential step toward building a circular economy in the textile sector, where waste is reabsorbed into the supply chain instead of landfilled or incinerated.

8. Hazardous and Medical Waste

Medical waste, such as syringes, expired drugs, and packaging, poses serious risks if not handled correctly. A dual shaft shredder is often used to pre-treat this waste before sterilization or incineration.

By shredding, the volume is reduced, and sharp items like needles are made safe for further treatment. This ensures compliance with strict regulations while protecting human health.

Industries that manage sensitive waste streams can benefit from equipment like the dual shaft shredder, which offers both power and precision to safely process hazardous inputs.

9. Agricultural Residue

Agricultural waste such as corn stalks, sugarcane bagasse, and palm fronds can be bulky and difficult to transport. By shredding these residues, farmers and biomass companies create uniform material that is easier to store, transport, or use for bioenergy.

A dual shaft shredder turns what was once considered waste into feedstock for renewable energy, fertilizers, or animal bedding. This represents a sustainable way to close the loop in agriculture.

10. Municipal Solid Waste (MSW)

Perhaps the most challenging application is unsorted municipal waste. A dual shaft shredder can reduce mixed household waste—including plastics, organics, metals, and textiles—into smaller fractions.

This makes downstream sorting more efficient, whether the end goal is recycling or waste-to-energy (WtE) processing. In this role, the shredder is like a gatekeeper, opening the path toward sustainable urban waste management.

Why Choose the Right Dual Shaft Shredder?

Not every shredder is built to the same standard. Factors like cutting chamber size, motor power, torque, and cutter material determine how effectively a shredder performs.

For companies handling varied waste streams, equipment such as the dual shaft shredder provides an optimal balance of strength, efficiency, and reliability. With its advanced blade design and robust construction, it handles continuous heavy loads with minimal downtime.

For a business, the right shredder is more than just a machine—it is a strategic investment. Like a reliable partner, it quietly works in the background, reducing costs, improving efficiency, and creating opportunities for new revenue streams through recycling and material recovery.

Conclusion

The dual shaft shredder is one of the most versatile and essential tools in the recycling and waste management industry. From metal scrap and e-waste to plastics, textiles, and municipal waste, it provides a consistent, powerful, and reliable solution for reducing diverse materials.

By adopting advanced solutions like the GIGAPA GTS-E dual shaft shredder, companies can unlock higher efficiency, lower operational costs, and stronger sustainability outcomes. Whether your business focuses on recycling, manufacturing, or waste management, the right shredder can turn today’s waste challenges into tomorrow’s opportunities.

-200x45.png)