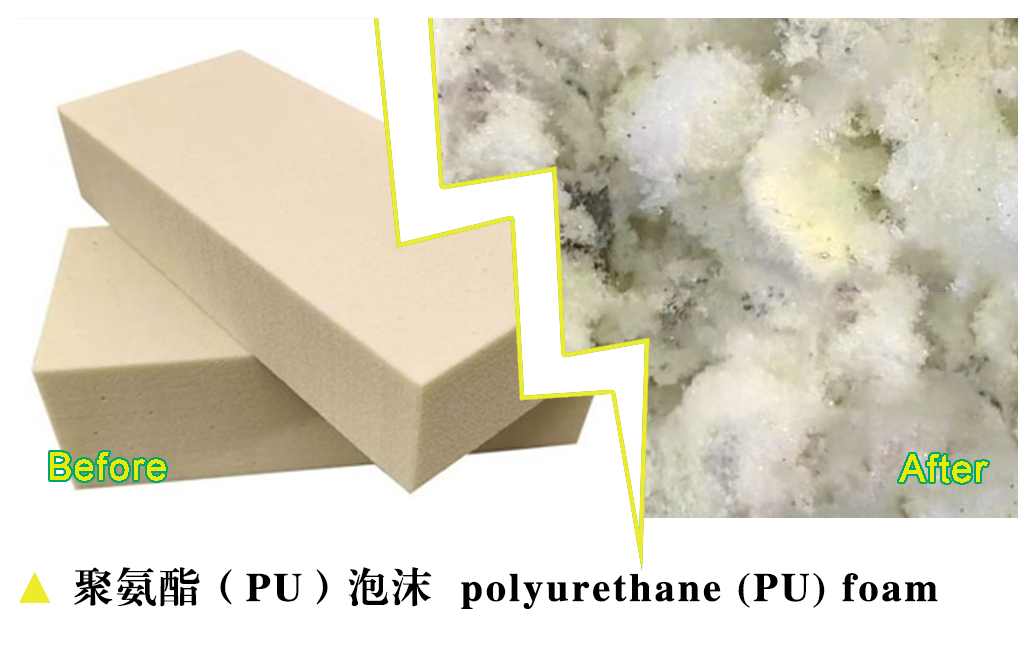

Introduction: The Need for PU Foam Recycling

Polyurethane (PU) foam is widely used across multiple industries — from furniture and mattresses to automotive interiors, insulation panels, and packaging.

While PU foam provides excellent flexibility and comfort, it also generates large amounts of waste during production and post-consumer use.

Disposing of PU foam in landfills or through incineration is neither economical nor environmentally friendly. The growing demand for sustainable manufacturing and recycling solutions has made PU foam shredding machines an essential piece of equipment for recycling companies and foam processors.

Among various designs, the PU foam shredder machine stands out for its efficiency, stability, and versatility in processing soft materials.

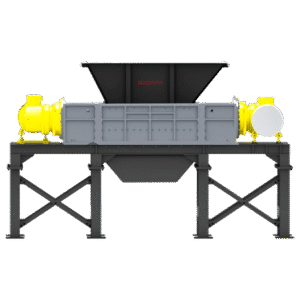

What Is a PU Foam Shredder Machine?

A PU foam shredder machine is a type of industrial shredder specifically designed for shredding soft and flexible materials such as polyurethane foam, sponge, memory foam, and insulation foam.

Unlike double-shaft shredders, the single-shaft design features one rotating rotor equipped with cutting blades and a hydraulic pushing system that feeds the material steadily into the cutting chamber.

This configuration ensures precise control over output size, low noise operation, and high energy efficiency — ideal for processing lightweight foam waste.

Key Components Include:

- Heavy-Duty Rotor: The main rotating shaft fitted with high-strength blades designed for flexible foam materials.

- Hydraulic Pusher: Automatically feeds foam into the rotor to ensure continuous shredding.

- Screen Mesh: Determines the final particle size; can be customized according to recycling needs.

- Electric Motor & Gearbox: Provide high torque at low speed for stable operation.

- Control Panel: PLC system ensures automatic operation, overload protection, and user safety.

How the PU Foam Shredder Works

The shredding process of a PU foam shredder machine is simple but highly controlled:

- Feeding: Foam waste is placed into the hopper.

- Pushing: The hydraulic ram pushes foam toward the rotor.

- Shredding: The rotor blades cut and tear the foam into smaller particles.

- Screening: The shredded material passes through a screen; oversized pieces are reprocessed automatically.

- Discharging: The finished foam flakes are discharged for reuse or further processing.

This closed-loop shredding process ensures a uniform output size, which is critical for subsequent recycling steps such as rebonding or compression.

Advantages of Using a PU Foam Shredder Machine

(1) Precision and Control

Single shaft shredders provide better control over the final particle size, making them ideal for applications requiring uniform shredded foam.

(2) Low Speed, High Torque Design

The machine operates at low speed but with high torque, ensuring smooth and stable shredding without clogging or overheating.

(3) High Efficiency with Minimal Maintenance

Fewer moving parts mean lower wear and tear. The machine is easy to maintain and designed for long-term industrial use.

(4) Energy Saving and Environmentally Friendly

By recycling PU foam waste instead of sending it to landfills, manufacturers can reduce disposal costs and environmental impact.

(5) Versatile Application

It can process different types of foam materials — including PU foam, sponge, EPE, EPS, and PE foam — making it suitable for multiple industries.

Applications of PU Foam Shredder

The versatility of the PU foam shredder machine allows it to be applied in a wide range of industries:

- 🛏 Mattress and Furniture Production: Shredding leftover foam pieces and offcuts for rebonded foam manufacturing.

- 🚗 Automotive Industry: Recycling seat cushion foam, insulation, and headrest materials.

- 🧱 Construction and Insulation: Processing foam boards, insulation panels, and soft PU foam sheets.

- ♻️ Recycling Plants: Preparing foam waste for further granulation or pelletizing.

- 📦 Packaging Industry: Shredding protective PU foam packaging for reuse or recycling.

The shredded foam can be reused for producing foam padding, carpet underlays, soundproofing panels, and even new PU products.

How to Select the Right PU Foam Shredder Machine

Choosing the best PU foam shredder machine depends on several operational factors:

(1). Foam Type and Density

Soft and flexible foam requires sharp, flexible blades, while denser foam may require more robust cutting edges.

(2). Output Requirements

Determine the ideal particle size based on your downstream processing (e.g., rebonding, compression, or re-extrusion).

(3). Production Capacity

Estimate your daily waste volume to select the appropriate motor power and chamber size.

(4). Maintenance and Service

Look for a supplier who provides technical support, spare parts, and after-sales service.

(5). Energy Efficiency

Machines with low-speed, high-torque motors consume less energy while maintaining strong shredding performance.

Why Choose GIGAPA Single Shaft Shredder

At GIGAPA, we specialize in manufacturing high-quality shredding and recycling equipment for solid waste processing.

Our single shaft shredder machines are built with over a decade of R&D and production experience, ensuring reliability, durability, and top-tier performance.

Key Advantages of GIGAPA Shredders:

✅ Advanced rotor design for soft materials like PU foam

✅ Optimized hydraulic feeding for stable throughput

✅ Energy-efficient operation with low noise and vibration

✅ Modular structure for easy blade replacement and maintenance

✅ CE-certified and widely exported to Europe, Southeast Asia, and the Middle East

We also offer customized designs based on foam type, output size, and plant layout, helping clients achieve the best balance between performance and cost.

Environmental and Economic Benefits

Using a single-shaft PU foam shredder machine brings both environmental and financial advantages:

- 🌱 Reduced Landfill Waste: Diverts tons of PU foam from landfills each year.

- 💰 Lower Disposal Costs: Minimizes transportation and handling expenses.

- 🔁 Material Reuse: Enables foam to be reprocessed into new materials.

- ⚙️ Energy Recovery: Shredded foam can be used in energy recovery systems when recycling isn’t feasible.

In the long term, investing in a PU foam shredder contributes to a sustainable and circular economy.

Conclusion

The single shaft PU foam shredder machine is the perfect solution for companies aiming to recycle foam efficiently and reduce environmental impact.

Its robust design, energy-efficient operation, and precise shredding performance make it ideal for handling PU foam, sponge, and other soft materials.

Whether you’re a furniture manufacturer, mattress producer, or recycling facility, integrating a single shaft PU foam shredder into your production line can help you:

- Improve waste management efficiency

- Reduce operational costs

- Support sustainability goals

At GIGAPA, we are committed to providing advanced shredding solutions tailored to your business needs.

-200x45.png)