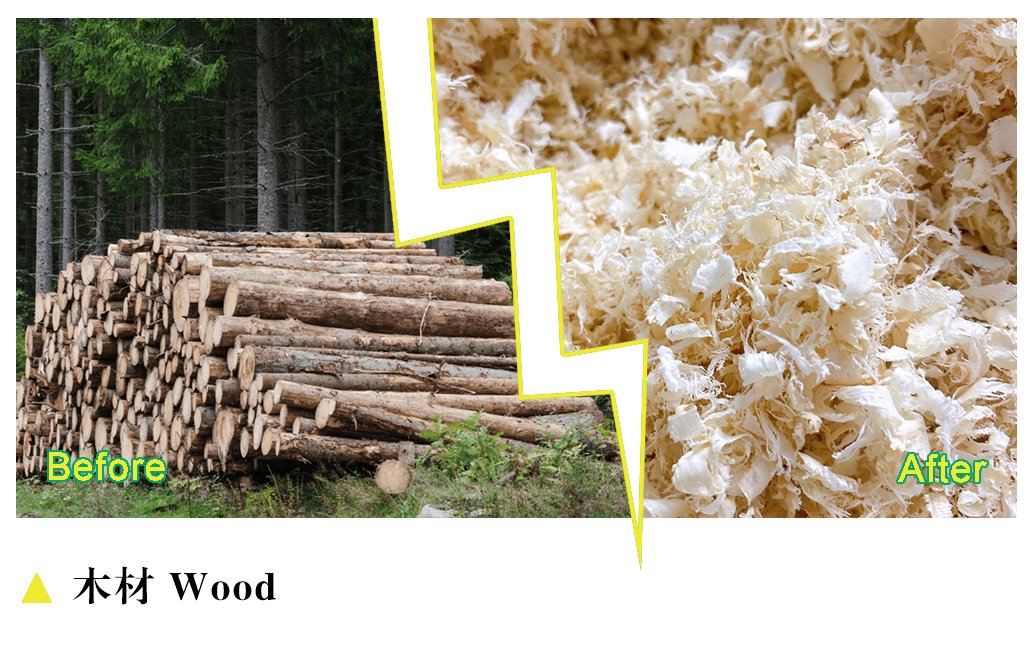

In the wood-processing industry, efficiency, consistency, and cost control are essential for maintaining competitiveness. Whether serving livestock farms, wood product manufacturers, or biomass industries, one machine has become indispensable for transforming raw logs into uniform, high-value shavings: the wood shavings machine. Also called a wood shaver or wood shaving mill, this equipment converts logs, branches, leftover timber, and offcuts into thin, fluffy shavings widely used in animal bedding, packaging materials, and industrial manufacturing.

As global demand for sustainable wood-based products continues to rise, more companies are adopting advanced wood shavings machines to optimize production, reduce labor intensity, and improve finished product quality. This article explores how a wood shavings machine works, the benefits it brings, common applications, and why investing in a modern, high-performance unit can greatly enhance operational efficiency.

What Is a Wood Shavings Machine?

A wood shavings machine is a specialized piece of equipment designed to slice wood materials into uniformly thin shavings. Unlike traditional wood chippers—which produce irregular, larger wood chips—a wood shavings machine uses precision-aligned blades and high-speed rotating cutters to generate consistently sized shavings with controlled thickness and texture.

The machine typically processes:

- Round logs

- Waste timber

- Wood blocks

- Slabs and offcuts

- Branches

Modern industrial wood shavings machines, such as the type your company provides, offer high output, adjustable shaving thickness, uniform flake size, low noise levels, and robust structural stability, making them suitable for heavy-duty continuous production.

How a Wood Shavings Machine Works

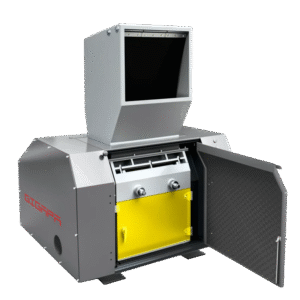

While the internal structure may vary depending on the model, the basic working principle of a wood shavings machine includes several key components:

1. Feeding System

Logs or wood scraps are fed into the machine through a controlled inlet. Some machines come with hydraulic feeding systems to ensure stable feeding speed and reduce manpower.

2. Cutter Head with Multiple Blades

The cutter head is the core of the machine. High-precision knives rotate at high speed to peel the logs layer by layer, similar to using a mechanical plane. The result is smooth, thin, uniform wood shavings.

3. Thickness Adjustment

Operators can adjust shaving thickness according to usage requirements. Most industrial-grade machines offer fine-tuning for industries requiring highly uniform products, such as horse bedding and packing material manufacturers.

4. Discharge System

The finished shavings are discharged through a conveyor or pneumatic system. High-quality machines produce shavings with consistent shape, low dust, and high fluffiness.

5. Safety and Stability Features

Modern designs include protective covers, overload protection, emergency stops, and reinforced frames to ensure safe, long-term operation.

Key Benefits of a High-Quality Wood Shavings Machine

A wood shavings machine is not simply a tool for producing shavings; it is an investment that significantly improves production capability and product quality.

1. High Production Efficiency

Industrial wood shavings machines can process large volumes of logs continuously, significantly reducing labor and time costs. They are ideal for farms, biomass pellet plants, and wood supply factories that need stable, large-scale production.

2. Adjustable Output for Multiple Applications

With adjustable shaving thickness and size, the same machine can serve multiple industries:

- Fine, thin shavings for horse and poultry bedding

- Medium shavings for pet bedding

- Thicker shavings for packaging and cushioning

- Material preparation for biomass fuel

This multi-functionality increases the value and flexibility of the machine.

3. Superior Shavings Quality

The machine produces smooth, dust-controlled, fluffy shavings that offer excellent absorption, cushioning, and cleanliness. High-quality shavings are especially important for:

- Equine farms (horses require soft, dust-free bedding)

- Poultry and cattle farms

- Pet care brands

- High-end packaging products

4. Reduced Waste and Increased Utilization

Scrap wood, branches, offcuts, and leftover materials can all be recycled, helping businesses reduce raw material costs and minimize environmental waste.

5. Strong and Durable Structure

A high-quality industrial wood shavings machine features:

- Heavy-duty steel frame

- High-strength cutter head

- Stable motor and transmission

- Long blade lifespan

This ensures long-term durability even under frequent continuous operation.

Where Wood Shavings Are Commonly Used

Wood shavings have wide applications across many industries. As a result, companies that produce shavings with modern machines gain access to multiple profitable markets.

1. Animal Bedding

Animal bedding remains the largest end-use market.

Wood shavings are favored for their:

- High absorption

- Soft and fluffy texture

- Natural smell

- Good insulation properties

- Easy cleaning and replacement

Used for:

- Horse stables

- Poultry farms

- Cattle and sheep farms

- Pet bedding (rabbits, hamsters, guinea pigs)

High-quality shavings command premium prices.

2. Packaging and Cushioning

Wood shavings offer natural, recyclable, and shock-absorbent protection. They are ideal for:

- Fragile product packaging

- Handcrafted goods

- Gift boxes

- Ceramic and glass items

- Wine bottle protection

Companies moving toward eco-friendly packaging prefer wood shavings over plastic materials.

3. Wood Products Manufacturing

Some industries use the shavings as feedstock for:

- MDF and particle board

- Biomass fuel

- Compost material

- Humus production

- Decorative landscaping

A stable supply of consistent shavings greatly improves downstream product quality.

Choosing the Right Wood Shavings Machine

When selecting a wood shavings machine, businesses should consider:

1. Raw Materials

Different machines support different wood types and sizes. Industrial models can handle:

- Large logs

- Hardwood and softwood

- Waste timber

2. Production Capacity

For commercial production, choose a model with high output and strong motor power to ensure stable operation during peak demand.

3. Blade Quality

Blades made from high-strength alloy steel significantly extend service life and maintain consistent shaving thickness.

4. Machine Stability and Safety

A good machine must include:

- Overload protection

- Emergency stop system

- Reinforced frame and bearings

5. After-Sales Support

Proper maintenance and blade replacement services ensure long-term productivity.

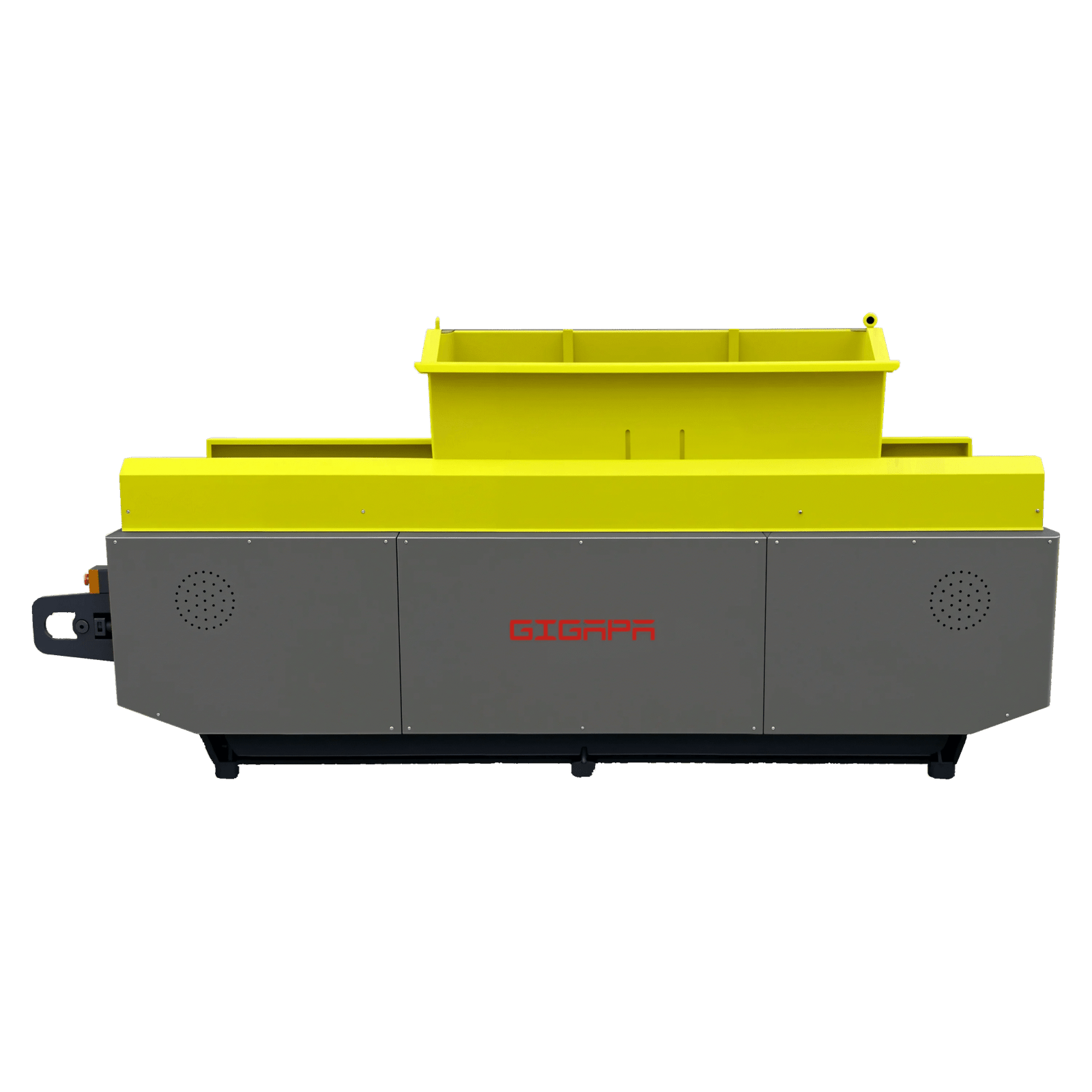

Why a GIGAPA Wood Shavings Machine Stands Out

GIGAPA’s wood shavings machine offers several advantages tailored for industrial customers:

- High-precision cutter head for clean, uniform shavings

- Adjustable shaving thickness to meet various industry needs

- High productivity suitable for farms and commercial plants

- Robust frame and stable structure designed for continuous operation

- Low noise and low dust output, ideal for modern production environments

- Flexible feeding options, supporting logs and wood blocks

These advantages make machine an excellent choice for customers seeking reliable, efficient, and high-quality wood shaving production.

Conclusion: Transforming Raw Wood Into High-Value Products

A wood shavings machine is far more than a simple cutting device—it is a powerful solution for generating high-value, environmentally friendly wood products. By transforming raw logs and waste wood into premium-quality shavings, businesses can expand their product range, reduce production waste, and boost profitability.

For farms, packaging companies, biomass processors, and wood product manufacturers, investing in a high-efficiency wood shavings machine enhances operational capability and ensures consistent product quality. Machines like the ones provided by your company are engineered for durability, output stability, and multi-purpose industrial use—making them a valuable asset in any modern production line.

-200x45.png)