In the metal recycling industry, efficiency and cost control are the cornerstones of sustainable profitability, and choosing the right copper wire baler is a decision that directly impacts both. Copper wire, a valuable and widely recycled material, requires proper processing to maximize its value and minimize logistical headaches. A high-quality copper wire baler compresses loose copper wires into dense, uniform bales, simplifying storage, reducing transportation costs, and ensuring smoother furnace charging during the recycling process. But with a wide range of models and configurations available on the market, how do you select the one that aligns with your business needs? This guide will walk you through the key factors to consider, helping you make an informed choice that boosts your operational efficiency and bottom line.

Understand the Basics of a Copper Wire Baler

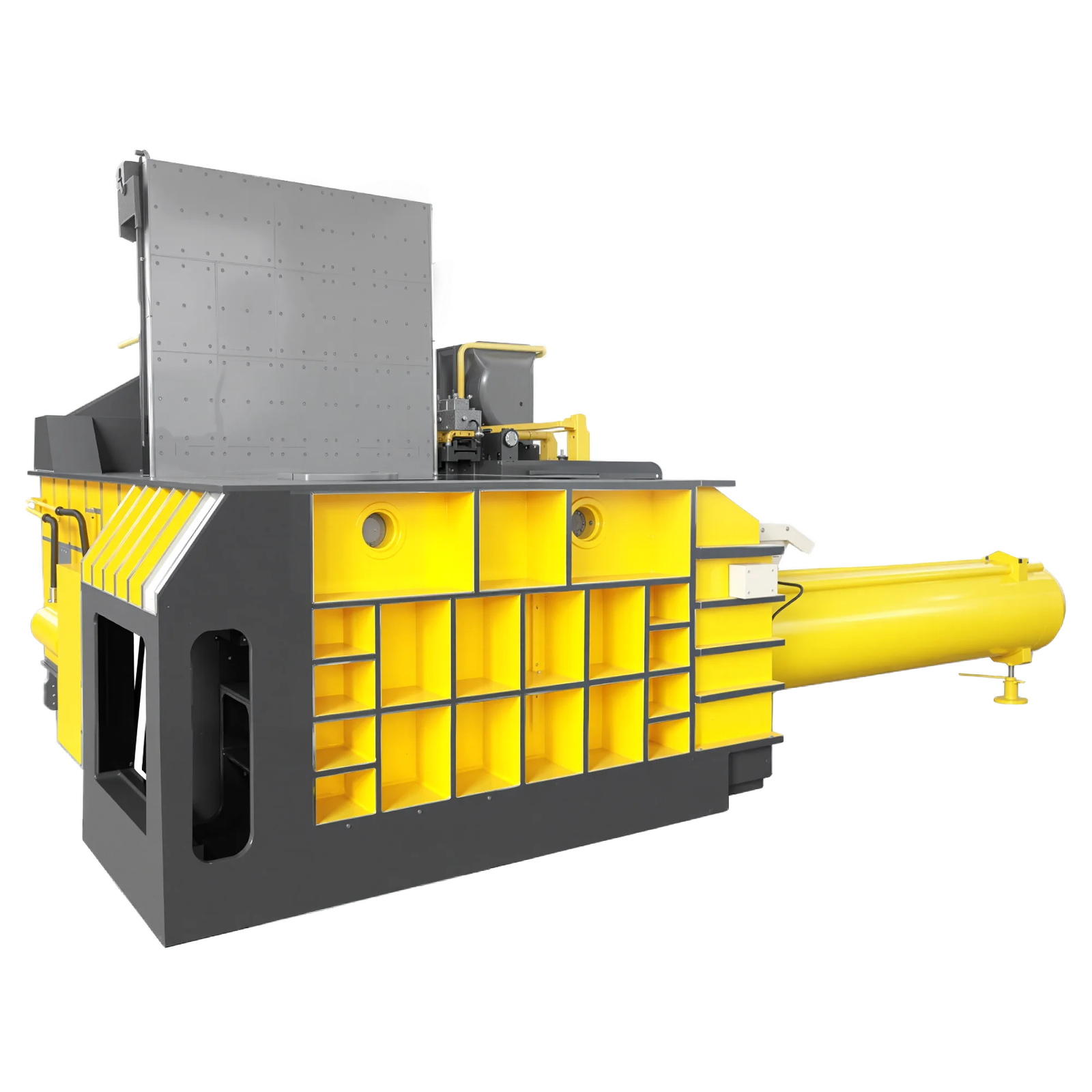

First, it’s essential to understand what a copper wire baler is and how it functions, as this foundational knowledge will guide your selection process. A standard copper wire baler consists of a frame, a door cover, a hydraulic cylinder, a pressing head, a package door, a hydraulic station, and other components. The door cover cylinder, side cylinder, and main cylinder work together to compress the metal material in three directions, respectively, ultimately squeezing it into a compact rectangular prism. This three-dimensional compression achieves the purpose of reducing volume and increasing bulk density—two critical benefits for any recycling business. The compressed blocks are convenient for loading and unloading, storage and transportation, and charging into furnaces, significantly reducing the costs throughout the entire metal recycling and regeneration industry chain, especially transportation and storage costs. By understanding these core functions, you can better evaluate whether a specific baler model can meet your operational requirements.

Assess Your Production Volume

The first factor to consider when choosing a copper wire baler is your production volume. Different baler models are designed to handle varying amounts of copper wire, and selecting a model that matches your daily or monthly throughput is crucial to avoiding inefficiencies or overcapacity. For small-scale businesses that process less than 5 tons of copper wire per day, a compact, semi-automatic copper wire baler may be the most cost-effective option. These models are typically smaller in size, require less upfront investment, and are easy to operate with minimal training. On the other hand, large-scale recycling facilities that process 10 tons or more per day will need a fully automatic copper wire baler with higher compression force and faster cycle times. Fully automatic models can handle continuous feeding, compression, and bale ejection, reducing the need for manual labor and increasing overall productivity. It’s important to assess your current production volume accurately and consider future growth projections—investing in a baler that can accommodate increased throughput will save you from costly upgrades down the line.

Evaluate Compression Force Requirements

Next, compression force is a critical technical specification that directly affects the quality of the bales and the efficiency of your operations. The compression force of a copper wire baler is measured in tons, and it determines how dense the final bale will be. Higher compression force results in denser bales, which means more copper wire can be transported or stored in a given space, further reducing logistics costs. For copper wire, which is relatively dense compared to other scrap metals, a baler with a compression force of at least 60 tons is recommended for small to medium-scale operations. For large-scale facilities or applications where maximum density is required, balers with compression forces of 100 tons or more may be necessary. It’s important to note that the compression force should be matched to the type and thickness of the copper wire you process—thicker, heavier gauge wire will require more force to compress effectively than thin, lightweight wire. Consulting with the manufacturer to determine the optimal compression force for your specific material is always a wise step.

Choose the Right Baler Configuration (Horizontal vs. Vertical)

Another key consideration is the type of baler configuration, which can vary based on your operational space and workflow. The most common configurations for copper wire balers include horizontal and vertical models. Vertical copper wire balers are ideal for businesses with limited floor space, as they take up less horizontal area and can be installed in smaller workshops or warehouses. These models are typically semi-automatic, requiring manual feeding of the copper wire into the compression chamber. They are well-suited for small-scale operations where space is a premium and production volume is moderate.

Horizontal copper wire balers, on the other hand, are designed for high-volume operations and offer greater automation. They feature a longer compression chamber and can be fed continuously using a conveyor belt, eliminating the need for manual feeding. Horizontal models also produce larger bales, which are more efficient for transportation. However, they require more floor space and a higher upfront investment. When choosing between horizontal and vertical configurations, consider your available space, labor resources, and production goals. If you have ample space and need to maximize throughput, a horizontal copper wire baler is the better choice. If space is limited and you can accommodate some manual labor, a vertical model will be more practical.

Prioritize Component Quality and Durability

The quality and durability of the baler components should also be a top priority, as a reliable machine will minimize downtime and maintenance costs. As mentioned earlier, a copper wire baler consists of several key components, including the frame, hydraulic cylinder, pressing head, and hydraulic station. The frame should be made of high-strength steel to withstand the high pressure of compression, ensuring long-term structural integrity. The hydraulic cylinder, which is the heart of the baler, should be constructed from high-quality materials with precise machining to prevent leaks and ensure consistent performance. Look for balers that use reputable hydraulic components from trusted manufacturers, as these parts are more likely to withstand heavy use and require minimal maintenance.

Consider Maintenance Ease and Spare Parts Availability

Additionally, consider the ease of maintenance and availability of spare parts when selecting a copper wire baler. Even the most durable machines will require regular maintenance to keep them running smoothly, so choosing a model with easy access to key components (such as the hydraulic station and pressing head) will simplify maintenance tasks and reduce downtime. It’s also important to ensure that the manufacturer offers readily available spare parts and reliable after-sales service. A lack of available spare parts can lead to extended downtime if a component fails, which can be costly for your business. Before making a purchase, research the manufacturer’s reputation for after-sales service and inquire about the availability of spare parts.

Don’t Overlook Safety Features

The safety features of the copper wire baler should not be overlooked, as workplace safety is a top priority for any business. Look for models that are equipped with safety features such as emergency stop buttons, safety interlocks on the door cover and package door, and protective guards around moving parts. These features help prevent accidents and ensure compliance with occupational safety regulations. Additionally, the manufacturer should provide comprehensive safety training materials and guidelines for operating the baler. Ensuring that your employees are properly trained to operate the machine safely will further reduce the risk of accidents.

Calculate Total Cost of Ownership

Cost is, of course, a significant factor in any business decision, but it’s important to consider the total cost of ownership rather than just the upfront purchase price. The total cost of ownership includes the purchase price, installation costs, maintenance costs, energy consumption, and the cost of downtime. A cheaper copper wire baler may have a lower upfront cost but could be less efficient, require more frequent maintenance, and have higher energy consumption, leading to higher long-term costs. On the other hand, a higher-priced model may offer better efficiency, durability, and lower maintenance costs, resulting in a lower total cost of ownership over time. When evaluating costs, consider the expected lifespan of the baler, the projected maintenance costs, and the energy efficiency rating. It’s also worth exploring financing options if the upfront cost is a barrier, as investing in a high-quality baler can yield significant returns in terms of reduced costs and increased productivity.

Conclusion

Choosing the right copper wire baler for your business requires a comprehensive evaluation of your production needs, operational constraints, and long-term goals. By considering factors such as production volume, compression force, baler configuration, component quality, maintenance ease, safety features, total cost of ownership, and customer feedback, you can select a baler that enhances your operational efficiency, reduces costs, and supports the growth of your business. Remember that a copper wire baler is an investment in the future of your business, and taking the time to make an informed choice will pay off in the long run. Whether you’re a small-scale recycler or a large industrial facility, the right copper wire baler will be a valuable asset that streamlines your operations and maximizes the value of your copper wire recycling efforts.

-200x45.png)