Lithium battery shredding plays a critical role in building a safe, efficient, and sustainable recycling system. It is the core mechanical process that enables the downstream separation and recovery of valuable materials such as lithium, cobalt, nickel, manganese, copper, and aluminum. For recycling plants, waste management companies, and battery manufacturers, investing in advanced lithium battery shredding technology is no longer optional—it is a strategic necessity.

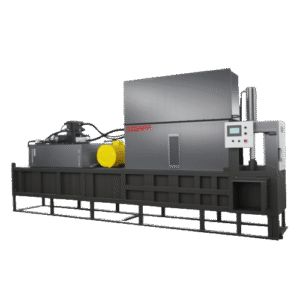

Compared with conventional crushing or grinding equipment, single-shaft shredders are specifically designed for controlled, low-speed, high-torque size reduction, making them especially suitable for lithium battery shredding. This article focuses on how lithium battery shredding is performed using single-shaft shredders, why this equipment is preferred, and how it contributes to safe, efficient, and sustainable battery recycling.

What Is Lithium Battery Shredding?

Lithium Battery Shredding refers to the mechanical process of tearing and cutting lithium batteries into smaller, uniform pieces under controlled conditions. The objective is not extreme pulverization but stable material liberation—separating battery casings, electrodes, and internal components so that valuable materials can be recovered in later stages.

Because lithium batteries contain residual energy, flammable electrolytes, and chemically active materials, shredding must be performed with equipment that minimizes heat generation, sparks, and mechanical shock. This is where the single-shaft shredder demonstrates clear advantages.

Why Lithium Battery Shredding Is Essential

Efficient Recovery of Valuable Materials

Lithium batteries contain a wide range of high-value materials, including lithium, cobalt, nickel, manganese, copper, aluminum, and graphite. Lithium battery shredding enables these materials to be effectively separated and recovered in subsequent processing stages, significantly improving recycling efficiency and economic value.

Environmental Protection

Improper disposal of lithium batteries can lead to severe environmental damage, including soil and groundwater contamination. Lithium battery shredding is a crucial first step in environmentally responsible recycling, ensuring that hazardous components are safely handled and processed.

Safety Risk Reduction

Waste lithium batteries pose serious fire and explosion risks during storage, transportation, and disposal. Industrial lithium battery shredding systems are designed to operate at low speeds with high torque, minimizing spark generation and thermal buildup.

Regulatory Compliance

As governments worldwide strengthen regulations on battery recycling, lithium battery shredding helps recycling facilities comply with environmental, safety, and waste management standards.

Why are Single-Shaft Shredders Ideal for Lithium Battery Shredding?

Low-Speed, High-Torque Operation

Single-shaft shredders operate at low rotational speeds with extremely high torque. This design is critical for lithium battery shredding because it:

- Reduces friction heat

- Minimizes spark generation

- Prevents sudden battery rupture

- Allows stable cutting of metal casings and battery packs

Compared to high-speed crushers, single-shaft shredders offer significantly higher safety margins.

Controlled Shredding for Hazardous Materials

Lithium battery shredding requires controlled tearing rather than impact crushing. Single shaft shredders use a single rotating shaft with robust knives working against a stationary counter-knife, ensuring smooth, predictable shredding behavior.

This controlled process is essential when handling:

- EV battery modules and packs

- Lithium iron phosphate (LFP) batteries

- Industrial and energy storage batteries

Uniform Output Size for Downstream Processing

In battery recycling, the goal of shredding is to prepare materials for separation, not to turn them into powder. Single-shaft shredders are equipped with screen systems that control output particle size, ensuring uniform material for:

- Magnetic separation

- Air classification

- Gravity separation

- Hydrometallurgical or pyrometallurgical processes

Uniform output improves recovery efficiency and reduces downstream processing costs.

Typical Lithium Battery Shredding Process Using a Single-Shaft Shredder

Step 1: Battery Discharging and Pre-Treatment

Before lithium battery shredding, batteries must be fully discharged to eliminate electrical hazards. Large battery packs may also be dismantled into modules to improve shredding stability.

Step 2: Primary Lithium Battery Shredding

The discharged batteries are fed into a single-shaft lithium battery shredder. At this stage:

- Batteries are torn open safely

- Metal housings are cut and deformed

- Internal electrode materials are released

The low-speed shredding action ensures controlled processing even for thick aluminum or steel casings.

Step 3: Size Control and Material Discharge

The shredded material passes through a sizing screen. Oversized material is automatically recirculated until it reaches the target size. This ensures consistent output, which is essential for efficient separation and recovery.

Step 4: Dust Collection and Safety Monitoring

During lithium battery shredding, fine dust and gases may be released. Industrial shredding lines integrate:

- Dust extraction systems

- Gas filtration units

- Temperature monitoring sensors

These systems protect operators and maintain compliance with environmental standards.

Key Design Features of Single-Shaft Shredders for Lithium Battery Shredding

Heavy-Duty Rotor and Knives

Single-shaft shredders used for lithium battery shredding are equipped with wear-resistant knives designed to handle mixed materials, including steel, aluminum, copper, and plastics.

Hydraulic Pusher System

The hydraulic pusher ensures continuous and even feeding of batteries into the cutting area. This feature prevents material bridging and sudden load spikes, which is especially important when shredding irregular battery packs.

Enclosed Shredding Chamber

An enclosed shredding chamber helps contain dust, electrolyte vapors, and noise. It also improves safety and allows integration with inert gas systems if required.

Fire Prevention and Safety Options

For lithium battery shredding applications, single-shaft shredders can be equipped with:

- Temperature sensors

- Automatic fire suppression systems

- Explosion-proof electrical components

These features significantly reduce operational risks.

Types of Lithium Batteries Processed by Single-Shaft Shredders

Single shaft shredders are suitable for a wide range of lithium batteries, including:

- Lithium-ion (Li-ion) batteries

- Lithium iron phosphate (LFP) batteries

- Lithium polymer batteries

- EV battery modules and packs

- ESS and industrial battery units

- Consumer electronics batteries

Their flexibility makes them ideal for both small recycling plants and large-scale industrial operations.

Environmental and Economic Benefits

Efficient shredding improves material liberation, resulting in:

- Higher recovery rates of lithium, copper, and aluminum

- Reduced downstream processing costs

- Longer equipment lifespan due to low-speed operation

How to Choose the Right Single-Shaft Shredder for Lithium Battery Shredding

When selecting a single-shaft shredder for lithium battery shredding, key considerations include:

- Battery size and structure

- Required throughput capacity

- Target output particle size

- Safety and environmental requirements

- Integration with existing recycling lines

A properly selected shredder ensures stable performance and long-term operational reliability.

Future Trends in Lithium Battery Shredding Equipment

As battery technology continues to evolve, single-shaft shredders are also being optimized for lithium battery applications. Key trends include:

- Higher automation and smart control systems

- Enhanced fire prevention technologies

- Improved knife materials and wear resistance

- Full integration with automated recycling lines

These advancements will further strengthen the role of single-shaft shredders in lithium battery recycling.

Conclusion

Lithium Battery Shredding using single-shaft shredders is a cornerstone of modern lithium battery recycling. The low-speed, high-torque, and controlled shredding characteristics of single shaft shredders make them the preferred solution for handling hazardous lithium batteries safely and efficiently.

As global demand for battery recycling continues to grow, single-shaft shredders will remain a key piece of equipment, enabling recycling facilities to recover valuable resources while maintaining high safety and environmental standards.

-200x45.png)