Fully Automatic Horizontal Baler for Waste Cartons is becoming essential as the rapid expansion of e-commerce, logistics, manufacturing, and retail industries has led to a dramatic increase in waste cartons and corrugated cardboard packaging. Every day, millions of cardboard boxes are discarded by warehouses, factories, and distribution centres. Without proper waste management solutions, these cartons occupy valuable space, increase disposal costs, and contribute to environmental pollution.

To address these challenges, businesses worldwide are adopting fully automatic horizontal balers for waste cartons. These industrial machines compress loose cardboard into compact, high-density bales, making storage, transportation, and recycling more efficient and profitable.

What Is a Fully Automatic Horizontal Baler for Waste Cartons?

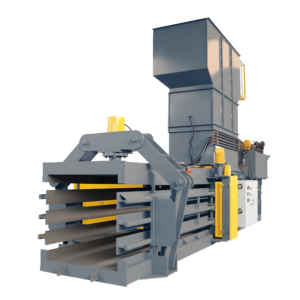

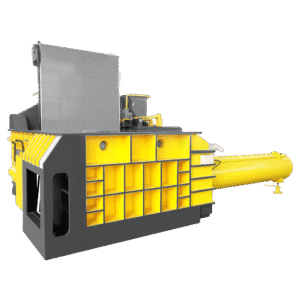

A fully automatic horizontal baler is a heavy-duty hydraulic machine designed to compress recyclable materials such as waste cartons, corrugated cardboard, paper, plastic film, and packaging waste into dense, uniform bales. Unlike vertical balers, horizontal balers are designed for continuous industrial operations and high-volume waste processing.

For waste cartons, a horizontal baler significantly reduces material volume, making it easier to store, transport, and sell to recycling companies. It is a key component of modern recycling systems and circular economy initiatives.

How Does a Horizontal Carton Baler Work?

The working process of an automatic horizontal baler is fully integrated and designed for efficiency and automation:

- Material FeedingWaste cartons and cardboard boxes are fed into the baler via conveyor belts, hoppers, or sorting systems. This allows continuous and automated material input.

- Hydraulic CompressionA powerful hydraulic cylinder pushes the cardboard into the compression chamber. High pressure compacts the material into dense bales with consistent dimensions.

- Automatic Bale TyingOnce the bale reaches the preset length and density, the machine automatically ties it with steel wire or plastic strapping. This ensures stable and transport-ready bales.

- Bale DischargeThe finished bale is automatically ejected from the baler chamber and is ready for storage, stacking, or shipment to recycling facilities.

This fully automated process minimises manual labour and ensures consistent bale quality.

Key Features of Fully Automatic Horizontal Balers

- High-Pressure Hydraulic SystemThe hydraulic system provides a strong compression force, producing high-density cardboard bales that meet international recycling standards.

- PLC Intelligent Control SystemPLC control with a touchscreen HMI allows operators to monitor machine status, adjust bale length, and control the entire baling process automatically.

- Continuous Feeding DesignHorizontal balers can be integrated with conveyors, shredders, and sorting lines, enabling continuous and large-scale waste processing.

- Heavy-Duty Machine StructureThe machine frame is constructed from thick steel plates with wear-resistant liners, ensuring durability and long service life in harsh industrial environments.

- Customizable Bale Size and DensityBale width, height, and length can be customized to meet recycling market requirements and logistics standards.

- Energy-Efficient OperationOptimized hydraulic circuits and motors reduce energy consumption while maintaining high productivity.

Advantages of Using a Fully Automatic Horizontal Baler for Waste Cartons

- Significant Volume ReductionLoose cardboard and cartons take up a large amount of space. After baling, the volume can be reduced by up to 80–90%, optimising warehouse and storage space.

- Lower Transportation and Handling CostsHigh-density bales maximise truck loading capacity, reducing transportation frequency and fuel consumption.

- Increased Recycling Value and RevenueCompacted cardboard bales can be sold to recycling companies, turning waste into a valuable resource and generating additional revenue.

- Reduced Labor CostsAutomatic feeding and tying reduce manual labor requirements, improving productivity and workplace safety.

- Environmental SustainabilityBy promoting cardboard recycling and reducing landfill waste, horizontal balers help businesses meet sustainability goals and comply with environmental regulations.

- Fast Return on Investment (ROI)Savings from reduced disposal costs and revenue from recycled materials can quickly offset the initial equipment investment, making horizontal balers a cost-effective solution.

Industrial Applications of Horizontal Balers for Waste Cartons

Automatic horizontal balers are widely used across multiple industries:

- E-commerce Fulfillment Centers: Managing large volumes of packaging cartons and boxes

- Logistics and Distribution Warehouses: Handling packaging waste from shipping operations

- Manufacturing Plants: Recycling cardboard packaging and paper scraps

- Recycling Facilities and Waste Transfer Stations: Compacting collected cartons for transport and export

- Supermarkets and Retail Chains: Compressing daily cardboard packaging waste

- Paper and Packaging Factories: Processing production scraps and rejected cartons

These applications demonstrate the versatility and importance of horizontal balers in modern waste management systems.

How to Choose the Right Horizontal Baler for Your Facility

Selecting the right machine is critical for maximising efficiency and ROI. Consider the following factors:

- Daily Waste VolumeEstimate the amount of waste cartons generated daily. High-volume operations require larger machines with higher motor power and throughput capacity.

- Bale Size and Recycling RequirementsDifferent recycling markets require specific bale dimensions. Ensure the baler can produce bales that meet local or international recycling standards.

- Automation LevelFully automatic balers are ideal for large-scale operations, while semi-automatic models may be suitable for smaller facilities with limited budgets.

- Installation Space and LayoutHorizontal balers require sufficient floor space for the machine, conveyors, and bale storage. Evaluate your site layout before installation.

- Power Supply and Energy ConsumptionCheck that the machine’s power requirements match your facility’s electrical system and energy efficiency targets.

- After-Sales Service and Technical SupportChoose a manufacturer that offers installation support, operator training, warranty, and spare parts supply to ensure reliable long-term operation.

Horizontal Baler vs. Vertical Baler: Key Differences

Many businesses compare horizontal balers with vertical balers before making a purchase decision.

Horizontal Balers:

Designed for continuous, high-volume industrial operations

Fully automatic feeding and tying

Higher bale density and larger bale size

Suitable for large recycling centres, warehouses, and factories

Vertical Balers:

Suitable for small-scale operations

Manual or semi-automatic operation

Smaller bale size and lower throughput

Ideal for retail stores and small workshops.

Understanding these differences helps businesses select the most suitable solution.

Operation and Maintenance Tips

Proper operation and maintenance ensure stable performance and extend the lifespan of your horizontal baler:

- Regularly check hydraulic oil levels and replace oil and filters according to the maintenance schedule.

- Inspect wear parts such as compression plates, seals, and tying wires, and replace them when necessary.

- Keep sensors, conveyors, and tying systems clean to ensure smooth operation.

- Train operators on safety procedures, emergency stop systems, and daily inspection routines.

- Conduct periodic professional inspections to prevent unexpected downtime.

Conclusion

The fully automatic horizontal baler for waste cartons is an essential machine for modern recycling and waste management operations. By compressing cardboard and carton waste into dense, uniform bales, businesses can reduce storage space, lower transportation costs, increase recycling profitability, and improve environmental sustainability.

For logistics centres, manufacturing plants, recycling facilities, and retail chains, investing in a high-performance horizontal baler provides long-term economic and environmental benefits. When selecting a baler, consider throughput capacity, automation level, bale size requirements, and after-sales support to ensure the best return on investment.

If you are looking for a reliable and efficient fully automatic horizontal baler for waste cartons, contact GIGAPA for detailed specifications, customized solutions, and competitive pricing.

-200x45.png)