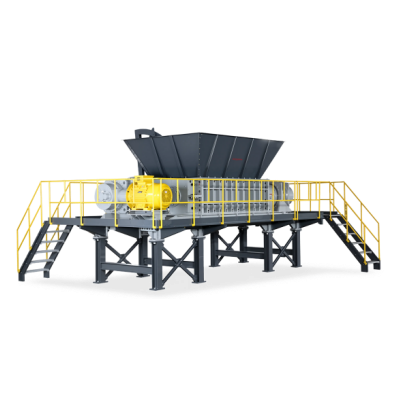

Equipment Introduction:

The double-shaft shredder cuts and tears materials into smaller sizes through the shearing and tearing action of the blades during their relative rotation, which facilitates subsequent processing or achieves the purpose of volume reduction. Thanks to its structural form and low-speed rotation, the dual-shaft shredder is characterized by high torque, strong shearing force, high processing capacity, good stability, and low noise. Therefore, it is widely used in the field of solid waste treatment and can meet the recycling and reuse processing needs of various types of solid waste.

Application Range:

| Industrial waste | tires, ceramic or glass products, leather and textile scraps, defective plastic products, defective electronic products, waste wood, waste paper, waste slag, waste materials, waste packaging, etc., and non-metallic waste. |

| Domestic waste | large items such as computers, refrigerators, washing machines, sofas, mattresses, disposable food containers, chopsticks, waste paper, plastic, and other metal or non-metallic waste |

| Bulk waste | disposable food containers, chopsticks, beverage bottles, waste paper, plastics, and other metallic or non-metallic waste materials |

| Agricultural waste | straw, tree branches, bamboo, animal carcasses, plastic mulch, etc. |

| Construction waste | construction wood forms, old doors and windows, gypsum boards, drop ceilings, color steel tiles, etc. |

| Medical waste | syringe waste, pharmaceutical waste, small medical equipment, used masks, surgical gowns, bed linen, and other medical waste. |

Model parameters:

| Model | GTS-E103 | GTS-E205 | GTS-E208 | GTS-E21 | GTS-E310 | GTS-E312 |

| Crushing chamber size (mm) | 300×300 | 520×500 | 810×500 | 980×516 | 1010×730 | 1170×730 |

| Swing diameter (mm) | φ170 | φ278 | φ278 | φ288 | φ400 | φ400 |

| Blade thickness (mm) | 20 | 30 | 30 | 30 | 40 | 40 |

| Motor power (kW) | 7.5 | 22 | 30 | 22×2 | 55×2 | 90×2 |

| Dimensions (L×W×H)(mm) | 1680×700×1790 | 2280×1540×2000 | 2580×1590×2000 | 3180×1820×2000 | 3760×2510×2910 | 4250×2910×2910 |

| Overall weight (kg) | Approx 800 | Approx 2300 | Approx 2700 | Approx 3300 | Approx 10000 | Approx 11800 |

The above models are standard universal models. If you require other models, please contact our staff, and we can also provide customized services according to your needs.

Technical Highlights:

1. Bearing life is long

Multiple protective measures are taken to extend the service life of the bearings

2. Low crushing resistance

Different blade profile designs are selected according to the requirements of the crushed materials to minimize crushing resistance as much as possible.

3. High crushing efficiency

The specially designed fixed knife not only serves as a material rejection function but also forms additional shearing with the moving knife, enhancing the overall crushing efficiency

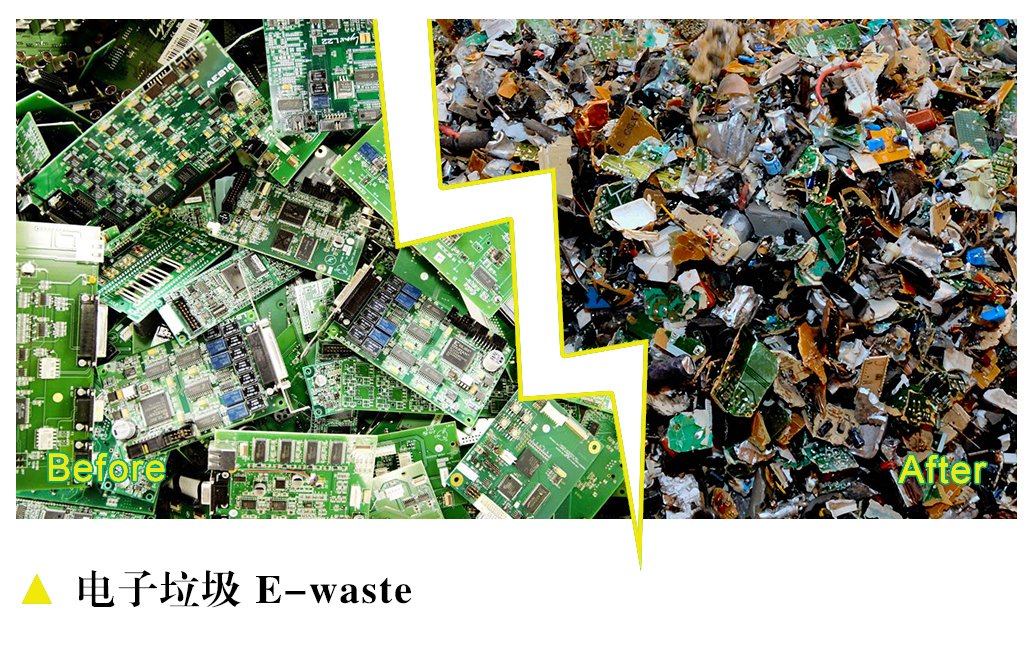

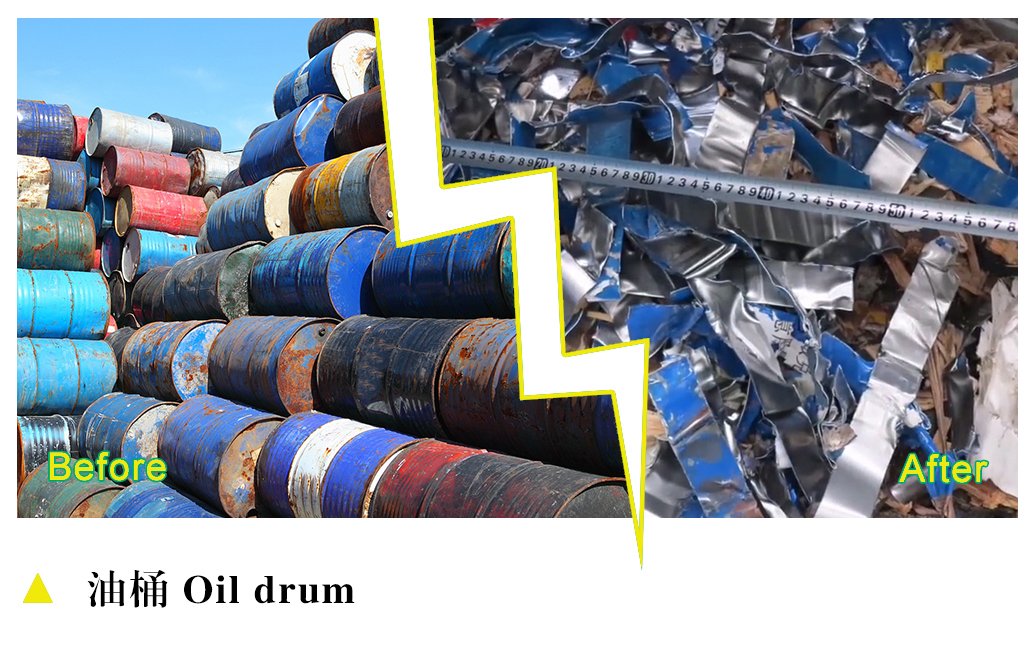

Effect Comparison:

Working Principle

A double-shaft shredder utilizes two parallel, counter-rotating shafts equipped with interlocking blades to shear, tear, and crush materials. When fed into the chamber, bulky waste is gripped and shredded between the rotating blades, which slice, rip, and compress it into smaller fragments. The slow-speed, high-torque design efficiently processes tough materials (e.g., metals, rubber) and features auto-reverse anti-jamming protection.

Double-Shaft Shredder vs. Single-Shaft Shredder

- Double-Shaft Shredder: Features two counter-rotating shafts with interlocking blades, utilizing shearing, tearing, and crushing forces for high-volume or mixed waste processing.

- Single-Shaft Shredder: Equipped with one rotor and stationary blades, designed for controlled size reduction of uniform materials at medium speeds.

5 Competitive Advantages

Double-Shaft Shredder

- Heavy-Duty Processing: Hydraulic system crushes metals, alloys, and mixed industrial waste.

- Anti-Jamming: Auto-reverse function protects against overload.

- Low Maintenance: Modular blades allow individual replacement.

- Screen-Free Design: Output size adjusted via blade spacing.

- High Throughput: Continuous processing capacity up to 3-20 tons/hour.

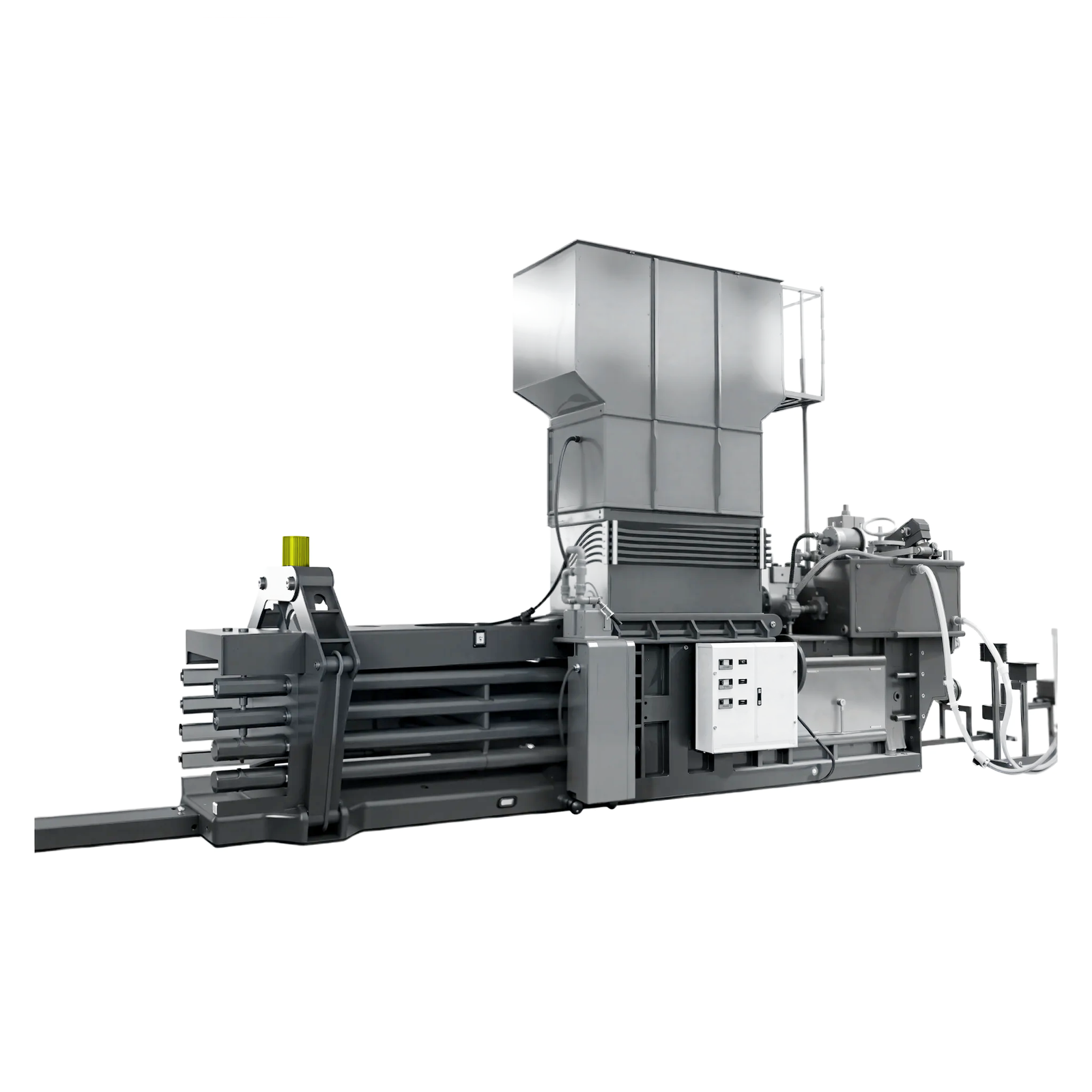

Single-Shaft Shredder

- Precision Shredding: Screen-controlled output for recycling granules.

- Quiet Operation: Noise levels below 75dB (ideal for indoor use).

- Energy Savings: 15%-30% lower power consumption vs dual-shaft.

- Compact Footprint: 40% smaller space requirement.

- Cost-Effective: 50%-70% lower upfront investment.

FAQ

1. What materials can a double-shaft shredder process?

Plastics, metals, e-waste, wood, rubber, paper, tires, and industrial scraps. It is ideal for recycling and volume reduction applications.

2. How does a double-shaft shredder work?

It uses two counter-rotating shafts with sharp blades to cut, tear, and shred bulky waste into smaller, uniform pieces. The process ensures efficient size reduction, making waste easier to transport, recycle, or reuse.

3. What industries use double-shaft shredders?

Industries such as recycling plants, manufacturing, automotive, packaging, metal processing, and waste management companies widely use our shredders for efficient waste handling.

4. How is the machine maintained?

Routine maintenance includes regular inspection of blades, lubrication of moving parts, and cleaning of the cutting chamber. Our shredders are designed for easy maintenance, and spare parts are readily available.

5. Can the shredder be customized?

Yes. GIGAPA provides customized shredding solutions tailored to your material type, capacity requirements, and plant layout.

6. Does GIGAPA offer after-sales service?

Absolutely. We provide global technical support, spare parts supply, remote troubleshooting, and on-site service if required.

7. How can I get a quote for a double-shaft shredder?

Simply contact us through the inquiry form, and our sales team will provide you with a customized quotation based on your material type, required capacity, and project needs.

8. What payment methods do you accept?

We mainly accept T/T for international orders.

-200x45.png)