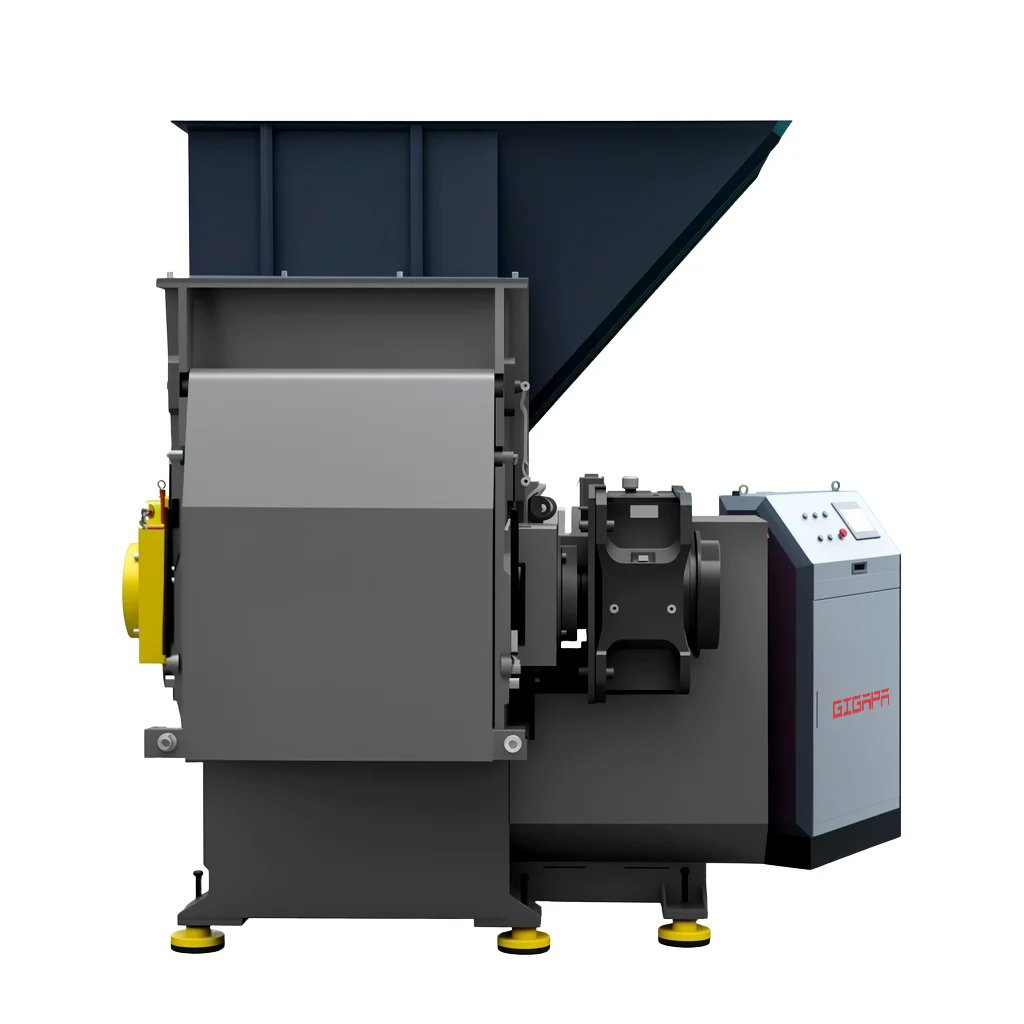

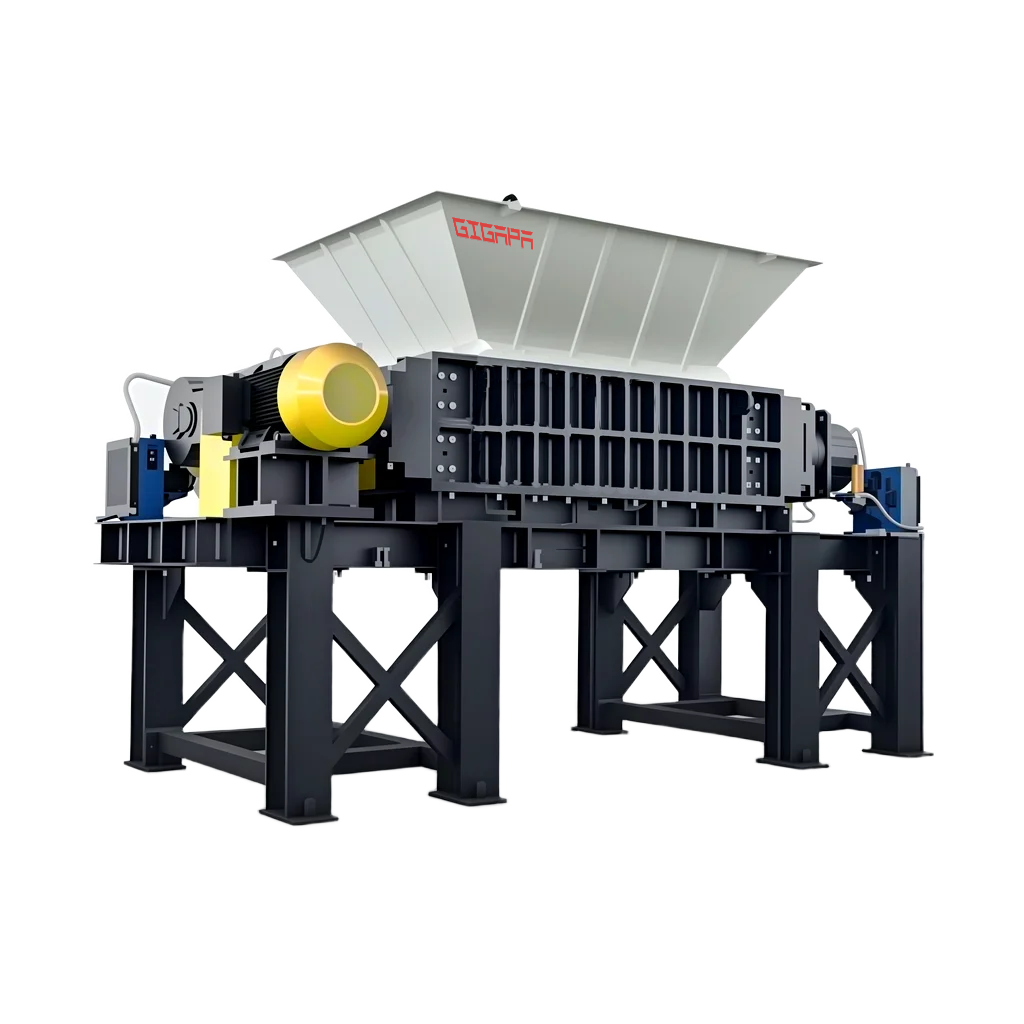

Equipment Introduction:

The vertical baling machine is powered by a hydraulic pump to drive the movement of the hydraulic cylinder, thereby moving the compression head to execute the compression action, achieving the purpose of reducing the volume of materials and increasing the bulk density. After compression, these materials generally cannot maintain their shape through complete deformation, so they need to be assisted in maintaining the compression effect through binding methods. Due to its strong versatility, small footprint, and simple operation, the vertical baling machine is widely used in enterprises with small processing volumes, especially supermarkets and small recycling stations that make extensive use of this type of vertical baler.

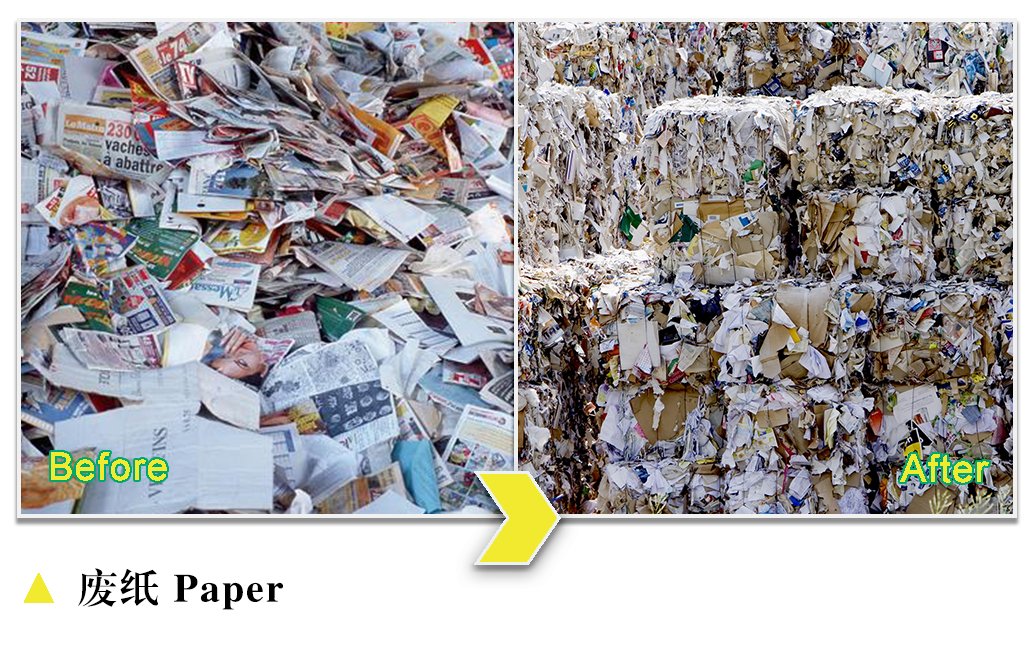

Application Range:

| Paper | Newspapers, magazines, books, wrapping paper, corrugated cardboard, cardboard boxes, paper boxes, advertising paper, various paper mill scraps, etc. |

| Plastic | Plastic bags, plastic packaging, plastic bottles, beverage bottles, mulch film, plastic film, woven bags, etc. |

| Fabric and leather | Leather scraps, textile mill scraps, garment factory scraps, carpets, clothing, curtains, plush toys, etc. |

| Plants | Various straws, tree branches, rice husks, etc. |

| Metal | Aluminum cans, aluminum profiles, etc. |

| Others | Household garbage, sponges, rubber strips, color-coated steel tiles, etc. |

Model Parameters:

| Model | GSB-V0604 | GSB-V0806 | GSB-V1107 | GSB-V1208 |

| Feed opening size (L×H) (mm) | 600×360 | 800×450 | 1100×550 | 1200×550 |

| Packing size (L×W×H)(mm) | 600×400×(400-640) | 800×600×(300-800) | 1100×700×(500-950) | 1200×800×(500-950) |

| Cycle time (s) | 25 | 50 | 50 | 47 |

| Number of strapping lanes (PCS) | 4 | 4 | 4 | 4 |

| Master cylinder inner diameter (mm) | φ90 | φ125 | φ110 | φ125 |

| Master cylinder pressure (T) | 16 | 31.5 | 25×2 | 31.5×2 |

| Hydraulic power (kW) | 2.2 | 4 | 5.5 | 7.5 |

| Dimensions (L×W×H)(mm) | 950×760×2070 | 1150×960×2850 | 1580×1080×3140 | 1680×1160×3280 |

| Overall weight (kg) | Approx 500 | Approx 850 | Approx 1500 | Approx 1850 |

The above models are standard universal models. If you require other models, please contact our staff, and we can also provide customized services according to your needs.

Technical Highlights:

1. Long service life of the machine

Made of high-quality steel and thickened steel plates, it remains fatigue-free and does not deform with long-term use.

2. Comprehensive safety protection

Multiple safety measures are in place to prevent potential hazards.

3. Easy operation for workers

A well-developed intelligent operation program ensures simple, worry-free operation and high efficiency

Working Principle

1. Loading Material

- vertical baling chamber from the top or side.

- The chamber is typically a sturdy steel structure with a hydraulic ram at the bottom.

2. Compression Process

- A hydraulic cylinder powers the ram, which moves upward to compress the material against a fixed top plate.

- The compression force can range from 10 to 100+ tons, depending on the machine’s size and material type.

- Multiple compression cycles may occur to achieve optimal density.

3. Bale Tying

- Once the material is fully compressed, the operator (or an automated system) inserts baling wire, strapping, or twine through pre-designed slots.

- The tied bale retains its shape after pressure is released.

4. Ejection

- The hydraulic ram retracts, and the finished bale is ejected from the chamber (either manually or via a tilting mechanism).

- Some models include a bale kicker to push the bale onto a pallet or conveyor.

5. Cycle Reset

- The machine resets, and the process repeats for the next batch.

FAQs

Q: 1. What is the difference between a vertical baling machine and a horizontal baler?

- Vertical: space-saving, suitable for small factories, supermarkets, etc., cheap, and more manual operation.

- Horizontal: large output, fully automatic, suitable for large recycling stations, but more expensive and takes up more space.

Q: 2. How long does it take to pack a waste paper box?

- Usually 3-5 minutes (including loading, compression, and bundling), the speed depends on the operator’s proficiency and machine performance.

Q: 3. How to maintain a vertical baling machine?

- Regularly add lubricating oil

- Check whether the hydraulic oil is sufficient

- Clean up the debris in the baling bin

- Pay attention to whether the baling rope/wire is normal

Q: 4. Can the vertical baling machine be bundled automatically?

- Semi-automatic: requires manual threading of wire or strapping (common in economical machines).

- Fully automatic: with automatic bundling device (higher price, suitable for frequent use).

-200x45.png)