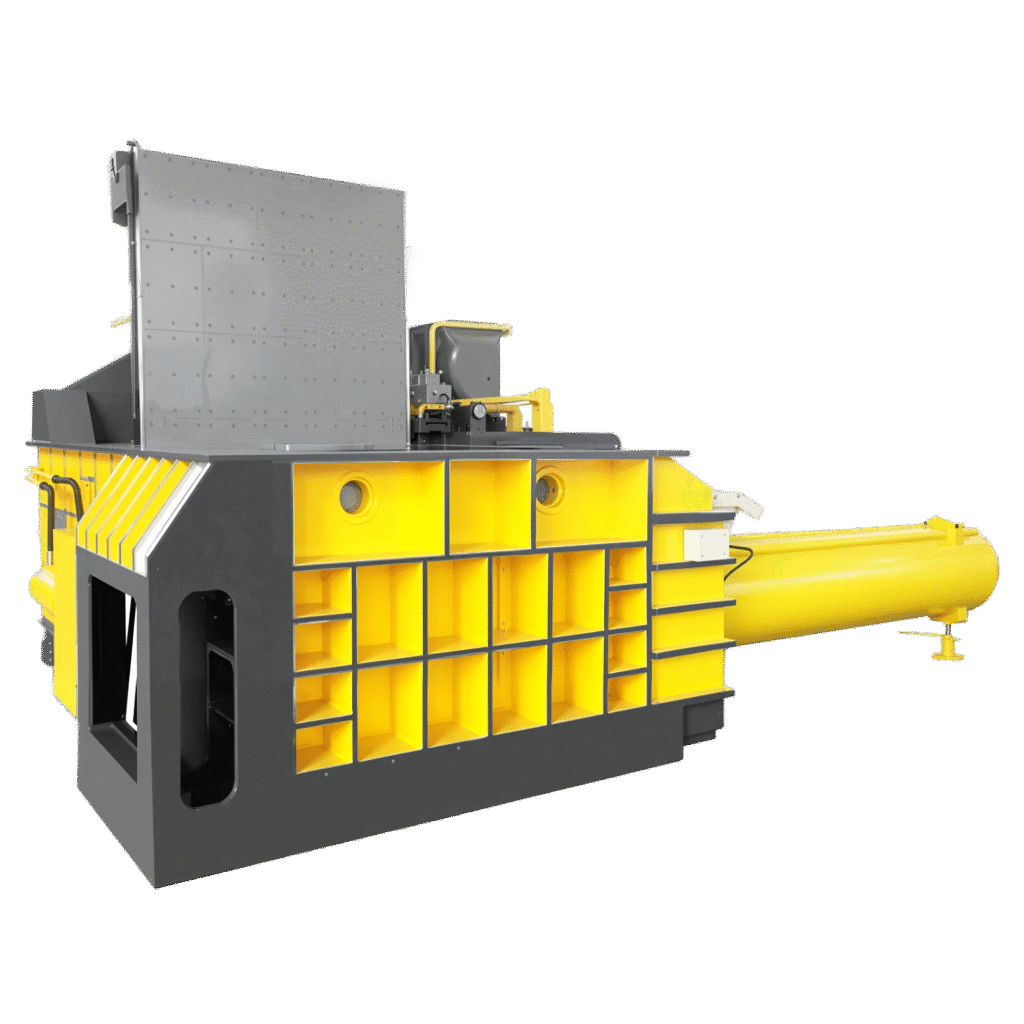

Equipment Introduction:

The door cover type metal baling machine, also known as the door cover type metal briquetting machine, consists of a frame, a door cover, a hydraulic cylinder, a pressing head, a package door, a hydraulic station, and other components. The door cover cylinder, side cylinder, and main cylinder compress the metal material in three directions, respectively, ultimately squeezing it into a compact rectangular prism. This achieves the purpose of reducing volume and increasing bulk density. The compressed blocks are convenient for loading and unloading, storage and transportation, and charging into furnaces, significantly reducing the costs throughout the entire metal recycling and regeneration industry chain, especially transportation and storage costs. Therefore, this equipment is particularly widely used in the field of metal recycling and regeneration.

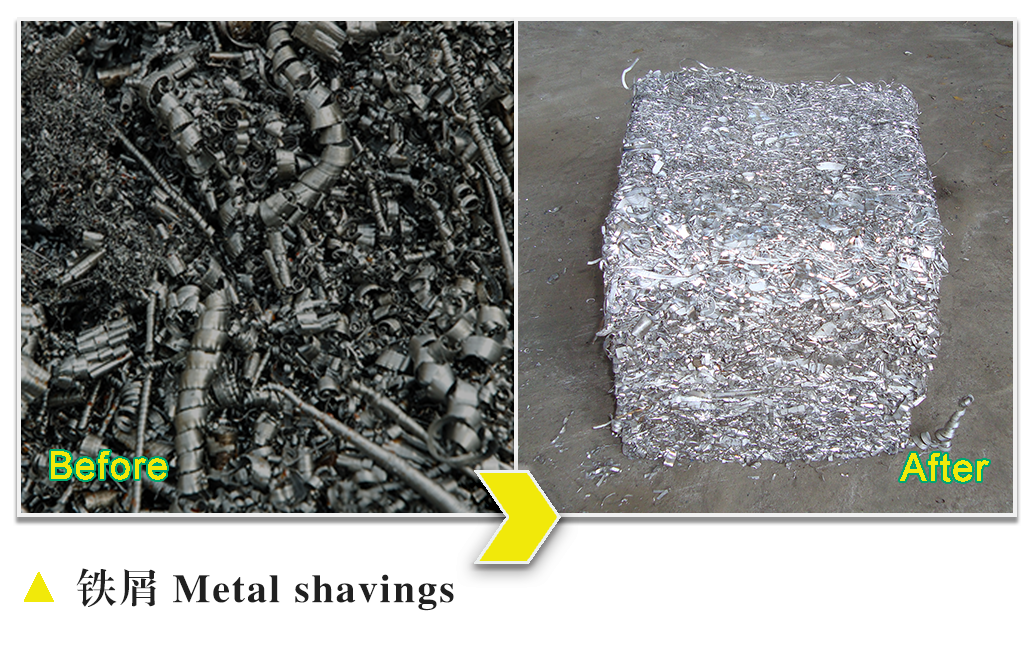

Application Range:

| General Metal Scraps | Aluminum cans, scrap steel, scrap iron, waste aluminum, waste copper, waste colored steel tiles, construction waste rebars, waste aluminum profiles |

| Ferrous Metal Granules | Granulated stainless steel chips, granulated steel chips, granulated iron chips, stamping scraps |

| Non-Ferrous Metal Granules | Granulated aluminum chips, granulated titanium chips |

| Structural Metal Waste | Disassembled car shells, household appliance shells, computer case shells; aluminum foil sorted from lithium battery electrode sheets |

| Manufacturing Byproducts | Granulated chips produced during the manufacture of refined plates |

| Miscellaneous Metal Waste | Silicon steel sheet scraps, oil filters, oil drums, paint cans, aluminum foil product scraps |

Model Parameters:

| Model | GFB-P2512 | GFB-P3512 | GFB-P4016 | GFB-P5025 |

| Packaging size (W×H×L)(mm) | 1200×700×600 | 1400×900×700 | 1600×1000×800 | 2000×1400×1000 |

| Main cylinder pressure (T) | 250×250 | 350×350 | 400×400 | 500×500 |

| Sub-cylinder pressure (T) | 125 | 125 | 160 | 250 |

| Hydraulic power (kW) | 11 | 15 | 22 | 45 |

| Dimensions (L×W×H)(mm) | 3200×2800×2000 | 3500×3200×2300 | 4100×3700×2600 | 4900×4650×3150 |

| Overall weight (kg) | Approx. 6000 | Approx. 8400 | Approx. 11300 | Approx. 21100 |

The above models are standard universal models. If you require other models, please contact our staff, and we can also provide customized services according to your needs.

Technical Highlights:

1. Durable and reliable

All surfaces in contact with materials are covered with wear-resistant plates, and key stress positions are designed with a large safety factor.

2. Stable and reliable

Bearings are added at the hinge points to improve the stability and reliability of the equipment operation.

3. Intelligent anti-tampering

The intelligent PLC program, meticulously crafted by engineers, effectively prevents equipment damage caused by accidental operation.

Working Process:

- Feeding: Metal scrap is loaded into the compression chamber manually or by conveyor belt

- Compression: Hydraulic cylinder applies 100-300 tons of pressure for multiple compressions

- Forming: Forming high-density rectangular blocks (density 2-5 tons/m³)

- Pushing out: Unique side push device pushes out the finished blocks completely

- Discharging: The blocks can be transported away by forklift or conveyor belt

- Reset: The equipment automatically resets and prepares for the next cycle

Core Advantages of Door Cover Metal Baling Machine:

High-Efficiency Production

- Capable of baling dozens of metal scrap bags per hour, far exceeding manual processing efficiency

Cost Optimization

- Compression reduces volume by over 80%, significantly reducing storage costs

- Regularized bales facilitate transportation, reducing transportation costs by 30%-50%

Value-Added Benefits

- High-density pure metal bales increase recycling prices by 15%-20%

Environmental Compliance

- Enclosed baling reduces contamination risks

- Fully complies with the latest environmental regulations

Management Improvements

- Standardized bales facilitate storage and management

- Enhancing the company’s green production image

(Equipment processing capacity can be customized according to needs)

FAQs

1. Q: Are you a hydraulic scrap metal recycling machinery manufacturer?

A: Yes, GIGAPA is a professional scrap metal recycling machinery manufacturer, focusing on the design and production of various types of scrap metal baling machines, shredders, metal briquetting machines and other mechanical equipment. We have many years of industry experience and technical accumulation, providing OEM and ODM services.

2. Q: Can you provide customized services?

A: Yes, we have rich customization experience and can design and produce products according to the specific needs of customers.

3. Q: What is the minimum order quantity?

A: The minimum order quantity is 1 set.

4. Q: How do you control product quality?

A: We have a strict quality control system, and all products will undergo strict quality inspection before packaging. If the customer is not satisfied with the product in any way, we will respond quickly and provide you with a solution.

5. Q: How to place an order?

A: The customer selects the product and tells us the required quantity. After confirming the details, we will quote. After the customer confirms and provides the delivery address, we will issue a pro forma invoice and wait for the customer to pay.

6. Q: What are the payment methods?

A: The payment method we accept is telegraphic transfer (T/T).

-200x45.png)