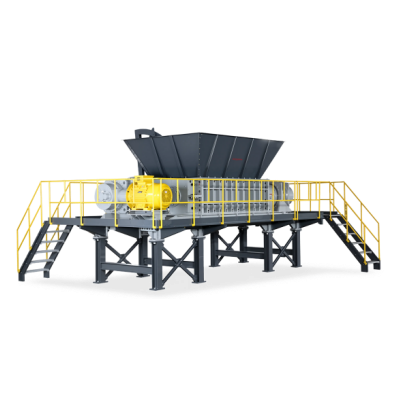

A scrap car shell shredder is a specialized crushing device designed for processing large metal waste, such as end-of-life vehicle shells. Driven by a powerful power system, the blades on the drive shafts exert multiple actions—including shearing, tearing, and crushing—on the scrap car shells. This process breaks down the originally bulky vehicle shells into uniform small pieces or fragments that meet the requirements for subsequent handling, facilitating transportation, recycling, reuse, or environmentally friendly treatment. A scrap car shell shredder typically includes a feeding system, shredding chamber, power transmission system, control system, and discharge system. It is capable of adapting to the shredding requirements of automotive shells of varying thicknesses and materials, including car bodies, doors, hoods, and other components.

A Scrap Car Shell Shredder Equipment Feature

- Powerful Shredding Capacity: Equipped with a high-torque motor and precision-engineered blades, this scrap car shell shredder effortlessly tears through thick car bodies, frames, and even reinforced structural components. It offers high processing capacity (customizable based on model), providing efficient support for large-scale operations.

- Durable Construction: Built with heavy-duty steel alloy, the machine’s rotor, housing, and cutting blades resist wear and impact, minimizing downtime and extending service life. The reinforced structure handles continuous use in harsh industrial environments.

- Advanced Safety Systems: Integrated safety features include emergency stop buttons, overload protection, and a safety interlock system to prevent accidents during operation. The enclosed design reduces noise and dust, complying with strict workplace safety standards.

- Customizable Output Sizes: Adjustable screen sizes allow operators to control the final fragment dimensions, meeting specific recycling or processing requirements for downstream applications like melting, sorting, or resale.

- Energy Efficiency: Optimized motor design and intelligent power management reduce energy consumption without compromising performance, lowering operational costs, and supporting sustainable practices.

Revealing the Shredding Process

A professional scrap car shell shredder operates like an industrial “steel monster,” equipped with powerful rotating cutter shafts and custom-engineered blades, capable of handling entire car bodies with ease.

Four-Step Shredding Process

- Pretreatment: Removal of Batteries, Tires, Fluids, and Hazardous Materials

- Compression: Flattening vehicles to reduce volume.

- Shredding: The giant shredder reduces vehicles into fist-sized fragments.

- Separation: Different materials are separated through magnetic separation, eddy current, and screening technologies.

Equipment Applications

- Automotive Recycling: The primary application is processing end-of-life (ELV) vehicle bodies, breaking them down into metal chips for recycling. This reduces landfill waste and recovers valuable ferrous and non-ferrous metals (steel, aluminum, and copper) for reuse in automotive, construction, or appliance manufacturing.

- Waste Management: Ideal for municipal or industrial waste facilities handling large volumes of scrap metal, including discarded car parts, appliances, and structural steel. It simplifies waste sorting and transportation by reducing material size.

- Metal Processing Plants: Provides feedstock for smelting and refining operations, as shredded metal fragments melt more efficiently than large scrap pieces, improving furnace productivity and reducing energy use.

- Sustainable Manufacturing: Supports circular economy goals by converting waste into high-quality raw materials, reducing reliance on virgin resources, and lowering carbon footprints for eco-conscious businesses.

Key Maintenance Points for Equipment

Daily Maintenance:

- Visual inspection of cutting components

- Lubrication check for all bearings and hydraulic systems

- Monitoring of vibration levels and abnormal noises

- Cleaning of the discharge area to prevent material buildup

Preventive Maintenance Schedule:

- Weekly: Tighten all bolts and fasteners; check drive alignment.

- Monthly: Inspect and rotate cutting components; test safety systems.

- Quarterly: Replace worn parts based on throughput volume; calibrate sensors.

- Annually: Perform a major overhaul, including bearing replacement and structural inspection.

Common Wear Parts and Replacement Indicators:

- Hammers/Blades: Replace when wear reaches 30–40% for optimal efficiency.

- Screen/Sieve: Replace according to the required output particle size.

- Conveyor Belt: Inspect for tears and misalignment issues.

- Electrical Components: Regularly test motors and drives.

Common Troubleshooting

- Reduced throughput capacity: Often indicates worn cutting elements or improper feeding.

- Abnormal vibrations: Check for rotor imbalance or foreign objects.

- Overheating: Verify proper function of lubrication and cooling systems.

- Material backflow: Adjust the discharge system or inspect for blockages.

Cutting-Edge Technology: A Smarter, More Efficient Shredding Future

Today’s automobile shredding industry has evolved far beyond simple “crushing” into a high-tech field integrating the Internet of Things (IoT) and Artificial Intelligence (AI). Intelligent sensors now monitor equipment status in real-time, while AI vision systems optimize sorting precision. Big data analytics are employed to predict maintenance needs. In some advanced facilities, material composition analysis can even trace the lifecycle history of each individual vehicle.

Why Choose Our Scrap Car Shell Shredder?

Choosing a scrap car shell shredder is beneficial because it serves as the “industrial giant pliers” that transforms mountains of discarded vehicle shells into high-value renewable resources. In the field of resource recycling, with its powerful shearing force and intelligent design, it is not only an efficient processing tool but also a core piece of equipment for achieving environmental compliance and economic benefits.

Scrap car shell shredder can effortlessly “chew through” large-volume, high-strength automotive metal shells, using low-speed, high-torque shearing to break them into uniform, high-density, regularly shaped fragments. This not only significantly saves transportation and storage space and greatly reduces logistics costs but also lays the foundation for subsequent processes such as magnetic separation and smelting. Modern shredders are further equipped with intelligent control systems, featuring automatic overload protection and real-time monitoring functions, ensuring continuous, stable, and safe operation of the production line.

With proven reliability, high efficiency, and compliance with international safety and environmental standards (e.g., CE, ISO), our shredder is a trusted solution for businesses looking to optimize scrap processing, boost profitability, and contribute to sustainable waste management. Contact us today to learn more about custom configurations and get a quote tailored to your needs!

Conclusion

The market prospects for scrap car shell shredders are optimistic, driven by the continuous increase in end-of-life vehicles, growing environmental awareness, technological advancements, and economic feasibility. Globally, the automotive scrap shredder market is projected to maintain steady growth in the coming years. From a technological evolution perspective, the industry is expected to accelerate its transition toward intelligent, modular, and environmentally friendly transformation over the next five years.

Scrap car shell shredder technology is driving profound transformation in the resource recycling industry toward higher efficiency and intelligence. From basic dual-shaft crushing and powerful four-shaft tearing to vertical fine processing, the core of equipment iteration lies in achieving higher-purity metal separation with lower energy consumption. With the application of IoT monitoring and AI recognition, traditional machinery has been upgraded into intelligent systems capable of self-adaptive adjustment, providing precise empowerment for the circular economy under the “dual-carbon” goals. In the future, this field will continue to focus on green energy efficiency and modular innovation, serving as a critical technological bridge connecting end-of-life vehicles with renewable resources, thereby offering solid support for sustainable development.

-200x45.png)