Working Principle of Hydraulic Horizontal Baling Press

A hydraulic horizontal baling press is an automated equipment that realizes material compression through hydraulic transmission system. Its core working principle can be divided into four key systems working together:

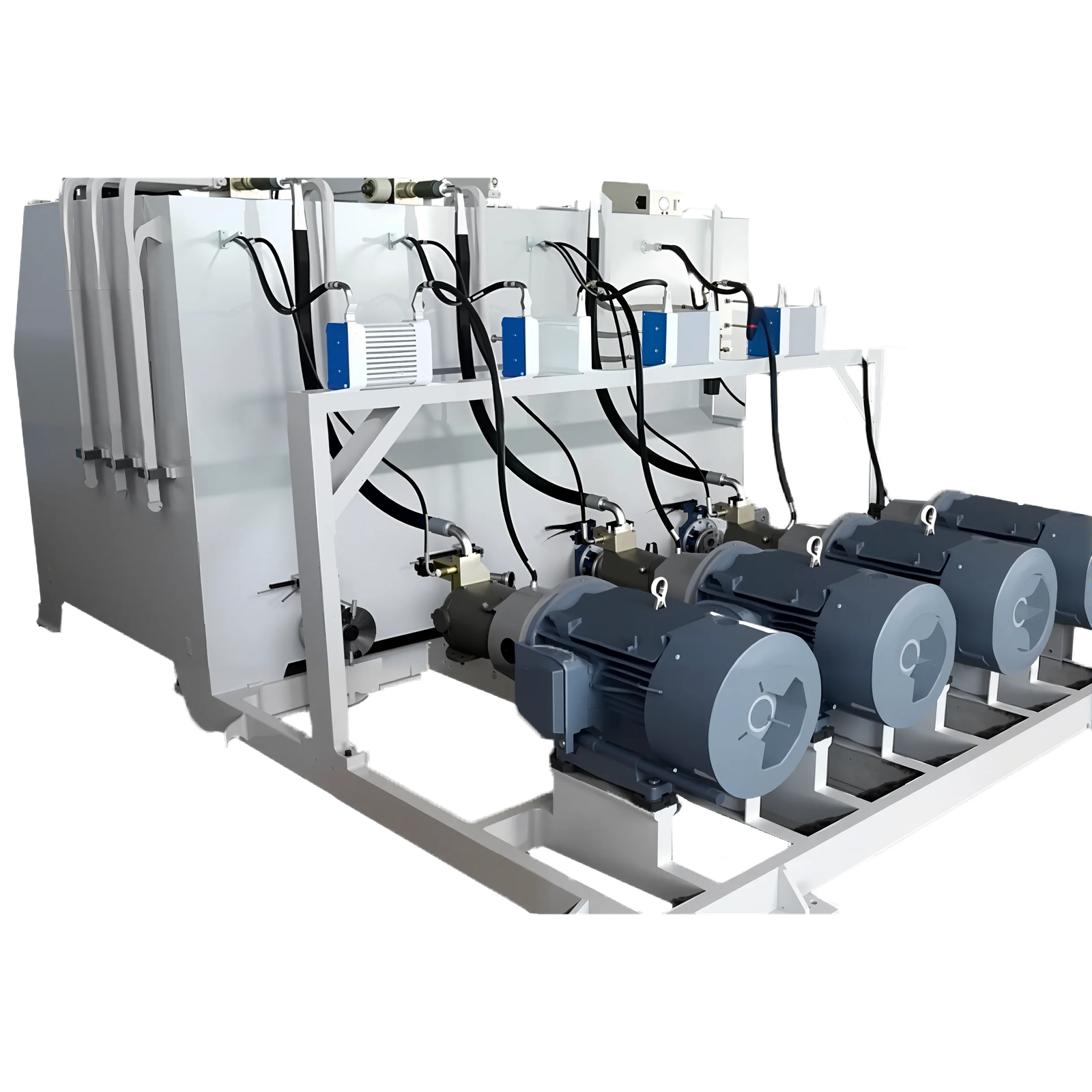

Hydraulic power system

- The motor drives the hydraulic pump to generate high-pressure oil flow

- The pressure regulating valve controls the output pressure (usually 15-30MPa)

- The hydraulic cylinder converts the oil pressure into mechanical thrust (typical thrust 50-300 tons)

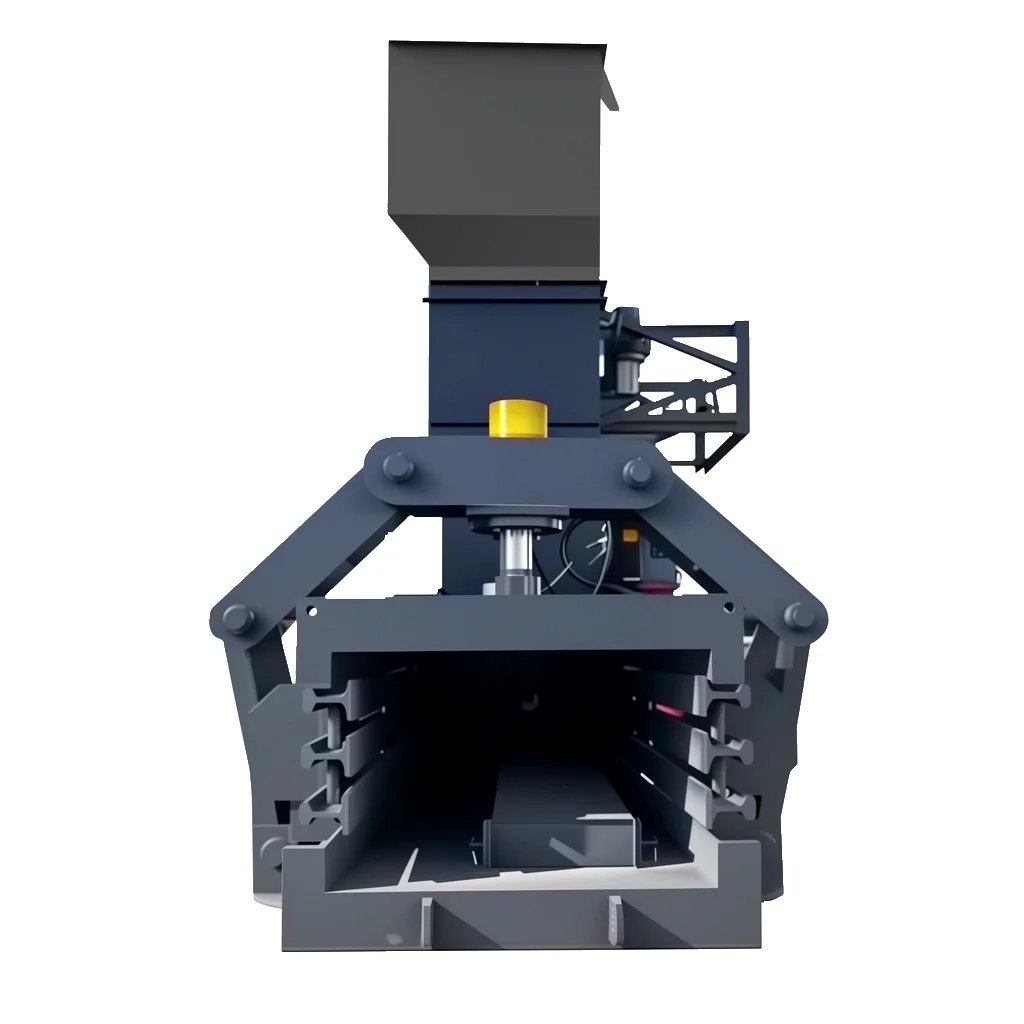

Material compression system

- Horizontally arranged compression chamber (size can be customized)

- The push plate is driven by the cylinder Downward linear reciprocating motion

- Progressive compression design (pre-compression + main compression two stages)

Automatic control system

- PLC programming controls the compression cycle (typical cycle 90-180 seconds)

- Photoelectric sensor monitors the material filling amount

- Pressure sensor realizes overload protection

Bundling output system

- Automatic threading/binding device (optional pneumatic or electric)

- Bag discharging mechanism (push bag/conveyor belt two methods)

- Door lock linkage safety device

Workflow:

Feeding → pre-compression → main compression → pressure holding and shaping → automatic bundling → bag discharging and resetting. The whole process is automated through electro-hydraulic linkage, and the compression ratio can reach 5:1 to 8:1, significantly reducing the volume of materials.

Maintenance Guide for Hydraulic Horizontal Baling Press

I. Daily Maintenance

Hydraulic System Inspection

- Check hydraulic oil level daily (keep above midpoint)

- Monitor oil temperature (normal range: 30-60°C)

- Inspect hoses/fittings for leaks (replace seals immediately if found)

Lubrication

- Apply grease to compression chamber rails daily (recommended: lithium-based grease)

- Clean hydraulic cylinder rods weekly and apply anti-rust oil

- Lubricate bearings with high-temperature grease every 3 months

Key Component Checks

- Inspect electrical wiring for wear (visual check monthly)

- Test emergency stop button function (weekly)

- Clean sensor surfaces to prevent false triggering

II. Scheduled Maintenance (Recommended Intervals)

| Item | Interval | Procedure |

|---|---|---|

| Hydraulic oil change | 2000 hours | Use anti-wear hydraulic oil (ISO VG46) |

| Filter replacement | 500 hours | Clean oil tank simultaneously |

| System pressure calibration | 6 months | Adjust relief valve to nameplate specs |

| Fastener inspection | 3 months | Focus on anchor bolts/cylinder mounts |

III. Common Troubleshooting

Low Pressure

- Check relief valve failure

- Test hydraulic pump output (requires pressure gauge)

- Verify cylinder internal leakage (pressure drop <10%/10min)

Overheating (>70°C)

- Inspect cooler for clogging

- Verify oil viscosity (46±5cSt at 40°C)

- Check for continuous overload operation

Abnormal Operation

- Solenoid valve sticking (clean or replace spool)

- PLC signal failure (inspect sensor wiring)

- Mechanical obstruction (remove foreign objects)

IV. Professional Maintenance Advice

- Schedule comprehensive inspection by manufacturer every 2 years (including cylinder seal replacement)

- Maintain equipment operation log (record pressure/temperature/maintenance)

- Operators must hold proper hydraulic equipment certifications

Safety Warnings:

▶ Always power off and release hydraulic accumulator pressure before maintenance

▶ Never disconnect pressurized hydraulic lines

▶ Dispose of waste oil through professional recycling channels

-200x45.png)