As the global shift toward electric mobility accelerates, the number of electric vehicles (EVs) on the road continues to rise dramatically. According to the International Energy Agency (IEA), global EV sales exceeded 14 million units in 2023, representing nearly 18% of total car sales worldwide. While this growth marks a major milestone for sustainable transportation, it also introduces an urgent challenge — the recycling and disposal of used lithium-ion batteries.

By 2030, it’s estimated that over 11 million tons of spent EV batteries will reach the end of their lifecycle. Without proper recycling, these batteries pose serious environmental and safety risks, including fire hazards, chemical leakage, and heavy metal pollution. To handle these challenges safely and efficiently, high-performance shredding equipment, especially double shaft shredders, has become an essential part of EV battery recycling systems.

The Importance of Safe Battery Shredding

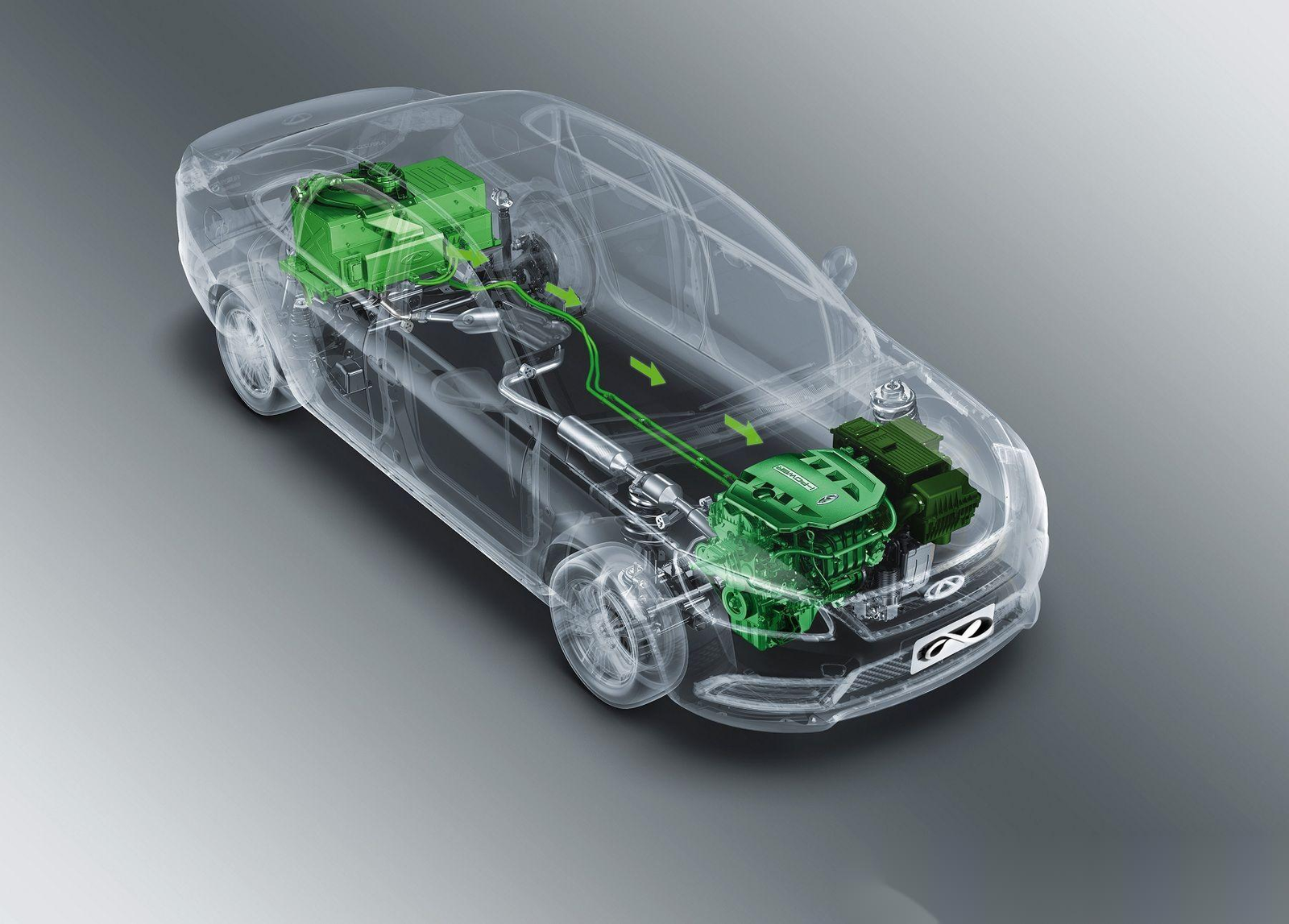

EV batteries are complex assemblies made up of lithium, cobalt, nickel, aluminum, copper, and various plastics. Before any material recovery can occur, batteries must be disassembled, discharged, and shredded under strictly controlled conditions.

This process is critical for three main reasons:

- Safety: EV batteries often retain residual charge. Improper handling can lead to short circuits or explosions.

- Efficiency: Shredding enables the separation of valuable materials for further chemical processing.

- Environmental protection: Controlled shredding prevents toxic gases or electrolyte leakage into the environment.

Because of these factors, recycling plants require robust shredding solutions that can safely process high-energy, high-density battery packs.

This is where double shaft shredders demonstrate unmatched advantages.

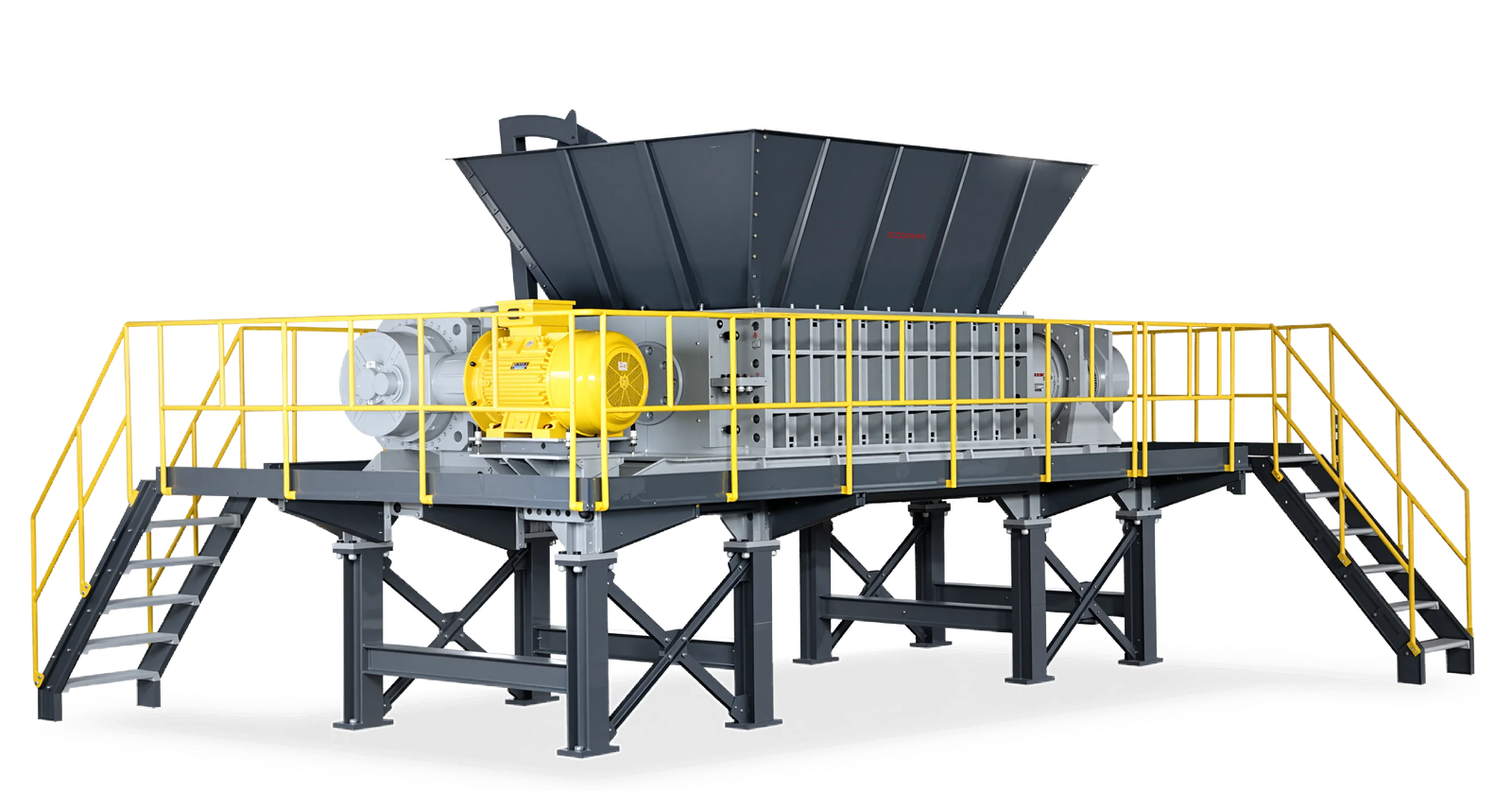

Why Choose a Double Shaft Shredder for Battery Recycling

A double shaft shredder (also known as a twin shaft shredder) uses two counter-rotating shafts with high-torque, low-speed cutting blades. Compared with single shaft or crusher systems, this design provides several key benefits for EV battery recycling:

(1) High Torque and Low Speed for Safety

Lithium batteries are extremely flammable when crushed at high speed. The double shaft design works at low rotational speed but high torque, minimizing the risk of sparks or overheating during operation.

(2) Excellent Material Adaptability

EV battery packs contain a mix of hard metals, soft plastics, and delicate electronic components. Double shaft shredders can handle diverse materials with ease, ensuring uniform particle size and stable throughput.

(3) Energy Efficiency and Durability

Equipped with hardened alloy blades and heavy-duty gearboxes, double shaft shredders are built for continuous operation, reducing maintenance downtime and energy consumption.

(4) Controlled Particle Size Output

The two shafts shear materials in opposite directions, allowing for precise size control that improves downstream separation efficiency in crushing, sorting, and smelting processes.

(5) Safety and Automation Integration

Modern double shaft shredders can be integrated with automatic feeding systems, nitrogen inerting devices, and explosion-proof chambers, making them ideal for EV battery recycling lines.

Technical Features of a High-Performance Double Shaft Shredder

A professional-grade lithium battery shredder typically includes the following design features:

| Feature | Description |

|---|---|

| Motor Power | 37–200 kW (customizable) |

| Cutter Material | High-strength alloy steel (resistant to wear and corrosion) |

| Cutting Speed | 10–30 rpm (low speed for safe shredding) |

| Output Size | 20–80 mm adjustable |

| Control System | PLC automatic control with overload protection |

| Cooling System | Optional water or nitrogen cooling to prevent overheating |

| Safety Design | Explosion-proof enclosure and gas collection interface |

These features ensure that EV batteries, modules, and even full packs can be processed efficiently and safely without compromising operator security or system stability.

Application Scope

High-performance double shaft shredders are widely used in various battery recycling operations, including:

- EV battery pack recycling (Lithium-ion, LFP, NCM, and other chemistries)

- Consumer electronics battery disposal (laptops, smartphones, power tools)

- Energy storage battery dismantling (solar or wind backup batteries)

- E-waste recycling (motors, circuit boards, aluminum housings)

By shredding the batteries into smaller fractions, recyclers can easily separate metal, plastic, and electrode materials, paving the way for further chemical leaching or pyrometallurgical recovery processes.

The Role of Shredders in the EV Battery Recycling Line

A typical EV battery recycling line includes several stages:

- Discharging and deactivation – neutralizing residual power to prevent accidents

- Shell dismantling – removing external covers and components

- Primary shredding – breaking down battery packs using a double shaft shredder

- Secondary crushing and sorting – separating anode/cathode materials

- Dust collection and electrolyte neutralization – ensuring clean operation

The double shaft shredder acts as the core equipment in the primary shredding stage, determining the efficiency, safety, and throughput of the entire recycling system.

GIGAPA Double Shaft Shredder: Reliable Partner for Battery Recycling

At GIGAPA, we specialize in manufacturing industrial-grade shredding and recycling machinery for solid waste and renewable materials.

Our Double Shaft Shredders are engineered specifically for lithium battery and EV recycling with the following advantages:

- ✅ Explosion-Proof Design: Optional nitrogen inerting and sealed chambers

- ✅ Customizable Blades: Optimized for aluminum shells, copper foils, and electrode materials

- ✅ Stable Operation: Heavy-duty gearbox and torque-limiting protection

- ✅ Easy Maintenance: Modular cutter replacement and automatic lubrication system

- ✅ Smart Control: PLC + HMI system for real-time monitoring and safety alerts

These machines are not only suitable for battery recycling plants, but also for metal recovery, e-waste treatment, and renewable energy facilities.

With over a decade of manufacturing experience, GIGAPA provides turnkey solutions from design and installation to after-sales service — ensuring that your recycling project operates efficiently, safely, and profitably.

Environmental and Economic Benefits

Recycling lithium batteries with a double shaft shredder brings both environmental protection and economic advantages:

- 🌍 Reduce carbon emissions: Recycling avoids energy-intensive mining of cobalt, lithium, and nickel.

- 🔋 Recover valuable metals: Up to 95% of valuable materials can be reclaimed from EV batteries.

- 💰 Lower disposal costs: Efficient shredding reduces transportation and processing expenses.

- 🛡️ Enhance safety: Controlled shredding eliminates fire and explosion risks in the recycling line.

These benefits make battery shredding an integral part of the circular economy for electric vehicles.

Conclusion

As EV adoption surges worldwide, the demand for safe and efficient lithium battery recycling equipment will continue to rise.

High-performance double shaft shredders have become the cornerstone of modern recycling plants — offering unmatched durability, safety, and adaptability for handling complex EV battery structures.

Choosing a reliable manufacturer such as GIGAPA ensures that your recycling operation not only meets global environmental standards, but also achieves maximum economic value from every ton of waste batteries processed.

-200x45.png)