Approximately 400 million tons of scrap metal are recycled worldwide each year, making it one of the most valuable and widely reused materials in the global economy. As demand for recycled metal continues to grow, recycling companies must employ efficient methods to handle and process this material.

Metal baler machines are crucial for this purpose. They convert bulky, irregularly shaped scrap metal into compact, manageable bundles, making them easier to store, transport, and further process. By significantly reducing the volume of scrap, metal balers help improve the efficiency of recycling operations, reduce costs, and support environmental sustainability across industries worldwide.

The Importance of Metal Baler Machines in the Recycling Industry

Scrap metal, including aluminum, steel, copper, and other metals, can often be bulky and difficult to manage. The metal baler machine addresses this challenge by compressing large volumes of metal waste into compact, manageable bales. This process makes it easier to store, transport, and reuse metal materials, significantly reducing handling costs and improving the overall efficiency of recycling operations.

Moreover, with the growing demand for recycled materials, industries such as metal recycling, automotive manufacturing, and construction are relying on efficient waste processing solutions. The metal baler machine is designed to meet this demand by offering high-density compaction, enhancing material handling efficiency, and ensuring safe operations.

How Does a Metal Baler Work?

A metal baler machine works by compressing large quantities of metal waste into compact bales, making it easier to handle, store, and transport. The baling process involves applying hydraulic pressure to scrap metal, squeezing it into a dense, manageable block that reduces storage space and increases the material’s transport efficiency. Metal balers are essential in industries like recycling, metal processing, and waste management, as they significantly improve productivity and lower costs.

In this section, we will focus on how two specific types of metal balers — the GFB-P Door Cover Metal Baler and the GFB-C Continuous Metal Baler — work, highlighting their features, benefits, and applications.

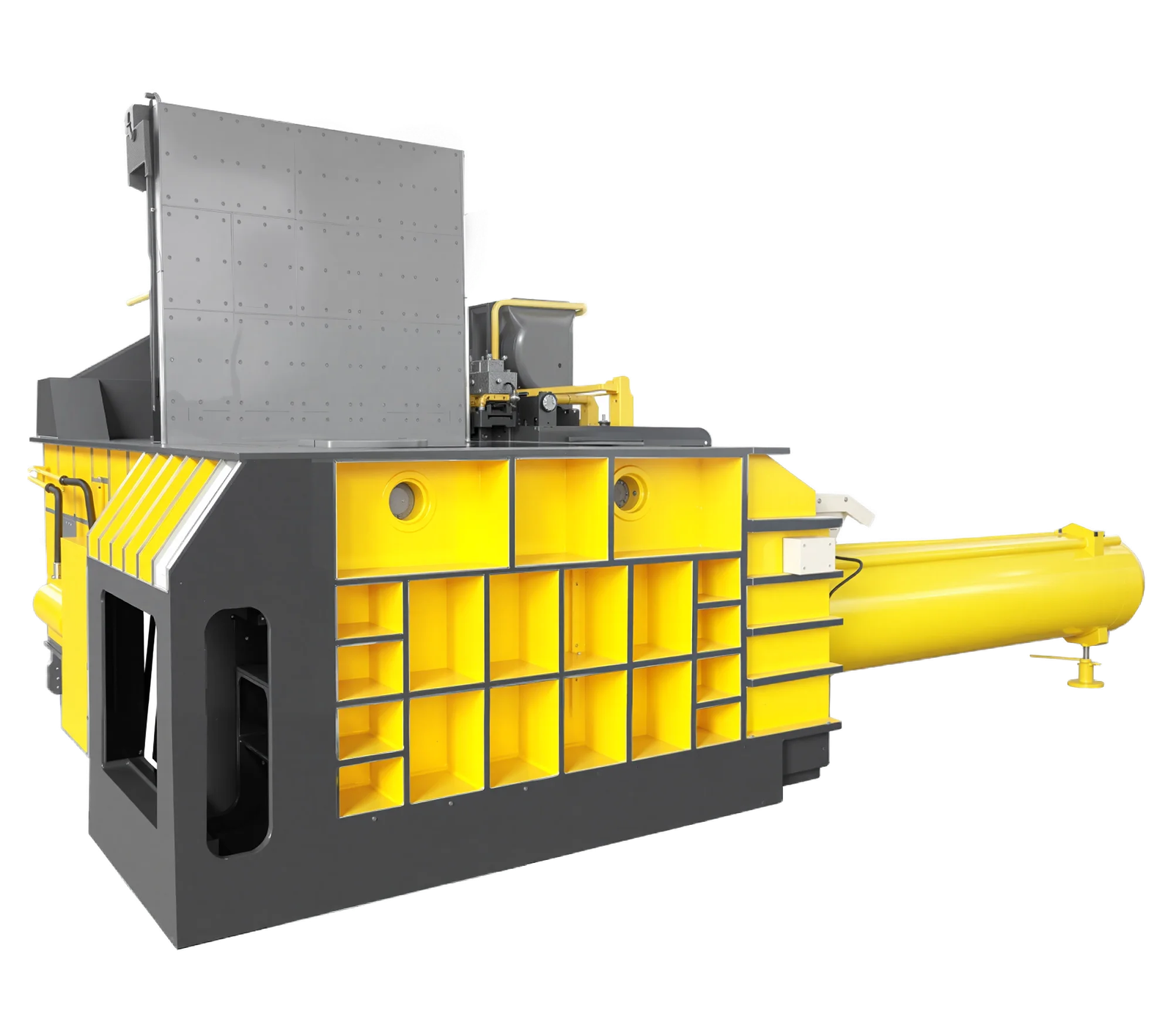

GFB-P Door Cover Metal Baler Machine

The GFB-P Door Cover Metal Baler Machine is designed for high-efficiency compression of scrap metal, including materials like aluminum, steel, and copper. This baler features a door cover design, which is essential for safely compressing metal waste while maintaining high-density bales. It is ideal for waste yards, recycling centers, and metal processing plants that require consistent performance and safety in handling large volumes of metal waste.

How It Works:

-

Material Loading:

The process begins when scrap metal is loaded into the baling chamber. The door cover design ensures that the metal is securely contained, preventing any debris or material from scattering during the compression process. -

Hydraulic Compression:

The machine utilizes a hydraulic system with multiple cylinders to apply powerful pressure in different directions. The side cylinders, main cylinder, and door cover cylinder work together to compress the material from three different angles, ensuring uniform and dense compaction. -

Bale Formation:

As the hydraulic pressure builds, the metal waste is compacted into a rectangular or cuboid shape, depending on the desired bale dimensions. The compact bales are tightly formed, which reduces their volume and increases their weight, making them easier to store and transport. -

Ejection of Finished Bales:

Once the compaction is complete, the bales are ejected from the chamber using a hydraulic ejection system. The finished bales are now ready for further processing, recycling, or transportation.

Key Features and Benefits:

- Safety and Control: The door cover design provides extra safety by keeping the metal waste securely contained, reducing the risk of accidents during operation.

- High Compression Density: The machine’s powerful hydraulic system ensures that the scrap metal is compressed into dense, heavy bales, making transportation and storage more efficient.

- Versatility: The GFB-P is suitable for handling a wide range of metal materials, including ferrous and non-ferrous metals such as aluminum, copper, and steel.

- Cost Savings: By reducing storage space and transportation costs, the GFB-P helps businesses cut down on operational expenses, improving overall profitability.

The GFB-P Door Cover Metal Baler Machine is perfect for businesses that need a reliable, high-performance machine for safely compressing scrap metal and improving material handling efficiency.

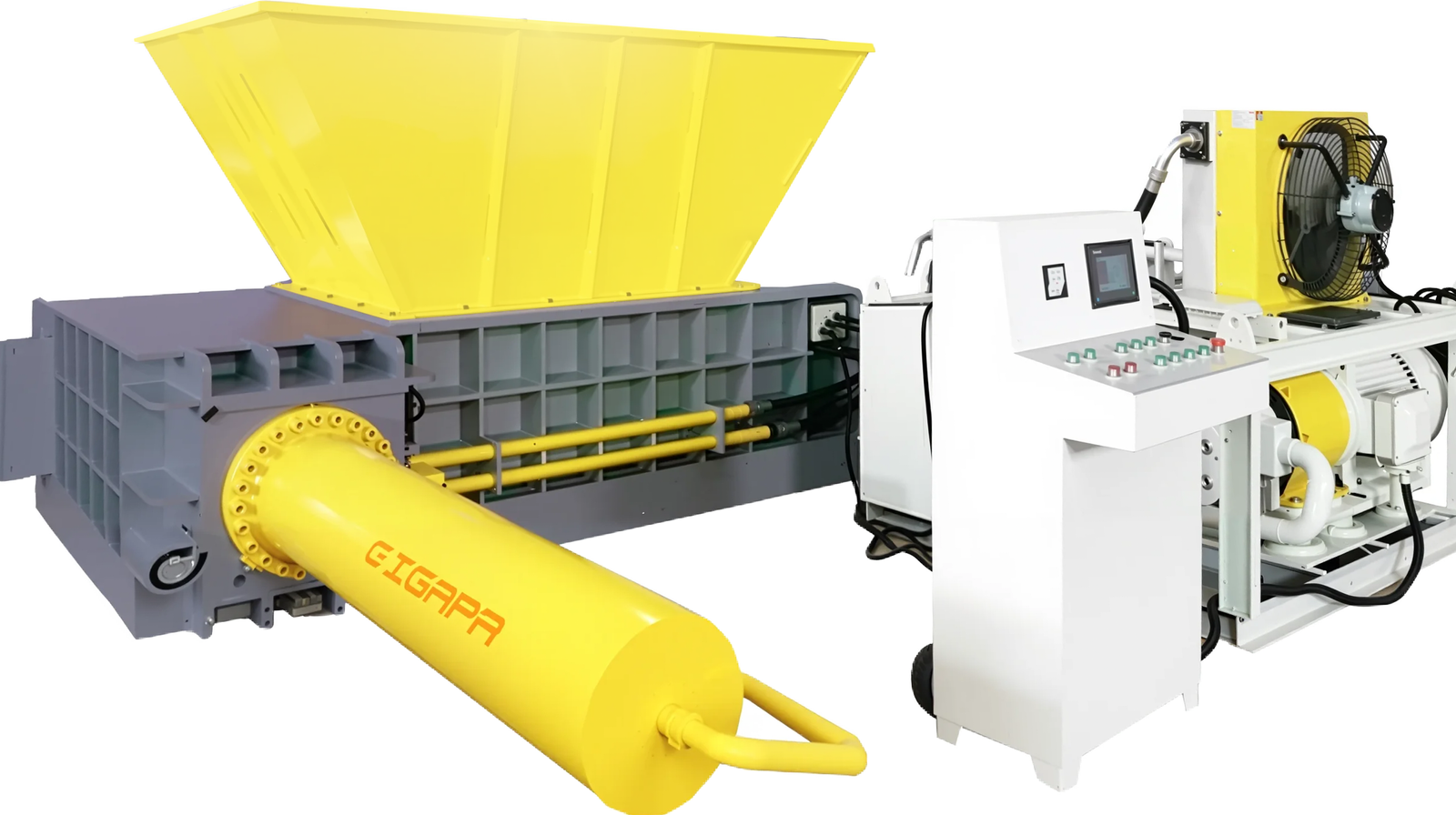

GFB-C Continuous Metal Baler Machine

The GFB-C Continuous Metal Baler Machine is designed to handle high volumes of metal scrap in a continuous, uninterrupted process. Unlike traditional balers that require manual loading and stop for each cycle, the GFB-C features a continuous feed system, allowing materials to be compressed and baled continuously without downtime. This makes it the ideal solution for high-volume operations, such as recycling centers, automotive manufacturing plants, and metal processing facilities.

How It Works:

-

Continuous Feeding of Material:

The GFB-C uses a hopper and conveyor system to continuously feed metal scrap into the baling chamber. This automatic feeding system ensures that there is no downtime between cycles, allowing the machine to operate efficiently and maintain high throughput. -

Hydraulic Compression Process:

Once inside the baling chamber, the metal waste is compressed using a hydraulic system. The system applies consistent pressure through multiple cylinders, ensuring uniform compression and high-density bales. The GFB-C can handle large volumes of material, even those with higher original densities, such as scrap metal from industrial manufacturing processes. -

Bale Ejection and Continuous Operation:

After compression, the finished bale is ejected from the chamber through a hydraulic ejection system. Because the machine operates continuously, this process happens with minimal interruption, leading to increased productivity and reduced labor costs. -

Liquid Removal:

A key feature of the GFB-C is its ability to expel liquid content during compression. This is particularly beneficial for materials such as aluminum scrap, where some liquid content can be removed, enhancing the bale’s density and cleanliness.

Key Features and Benefits:

- Continuous Operation: The GFB-C’s ability to continuously process metal scrap without stopping boosts productivity and efficiency. This is ideal for operations that handle large volumes of waste and require a high throughput.

- High Throughput and Low Downtime: The GFB-C can operate non-stop, making it perfect for businesses that need to process scrap metal around the clock. The minimal downtime between cycles allows for maximum output.

- Automated Integration: This baler can be easily integrated into existing production lines, facilitating seamless automation and reducing the need for manual labor.

- Improved Bale Quality: The continuous feed system and hydraulic compression ensure that each bale is uniformly compressed and of high quality. Additionally, the removal of excess liquids helps create cleaner bales, reducing contamination.

- Cost-Effective and Efficient: By reducing labor costs, improving throughput, and increasing operational efficiency, the GFB-C is a highly cost-effective solution for large-scale metal recycling operations.

The GFB-C Continuous Metal Baler Machine is ideal for businesses that need to handle large quantities of metal scrap efficiently and with minimal downtime. Its continuous operation and high-volume capabilities make it a go-to choice for businesses looking to scale their recycling operations.

Conclusion

In today’s world, where resource efficiency and sustainability are paramount, metal baler machines are indispensable in the recycling industry. Whether you’re processing aluminum, copper, steel, or other metal scrap, investing in a high-quality baler, such as the GFB-P or GFB-C, can help streamline your recycling process, reduce costs, and improve overall productivity. These machines not only enhance material handling and compaction capabilities but also ensure a safer, more efficient workplace while contributing to global sustainability.

-200x45.png)