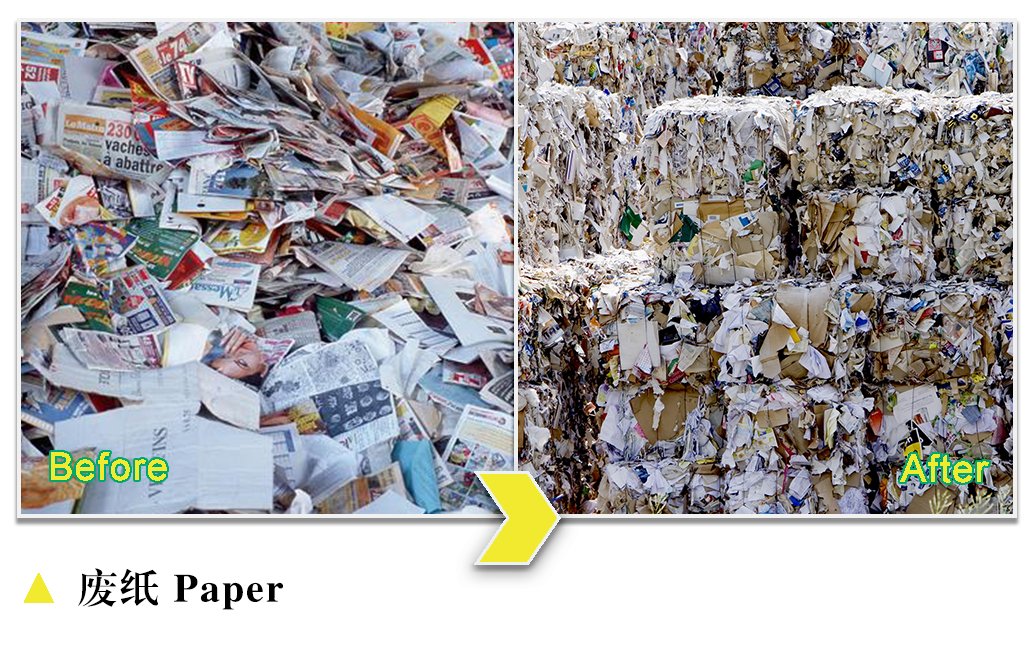

Loose waste paper presents a frequent problem in sectors such as printing, packaging, logistics, and recycling. If not properly managed, it can occupy important space, create safety risks, and hinder efficient transportation. The solution? An advanced horizontal hydraulic baler — especially one that is fully automatic and equipped with an automatic strapping system using PP belts or iron wire.

In this article, we will examine how a horizontal hydraulic baler addresses the problem of loose waste paper bundles and why companies around the globe are adopting fully automatic baling systems to enhance productivity, safety, and recycling efficiency.

Why Loose Waste Paper Bundles Are a Problem

Loose bundles of paper waste are:

- Bulky and space-consuming

- Difficult to move or stack

- Prone to scattering and creating workplace mess

- Costly to transport due to low density

- Prone to contamination, reducing recycling value

Whether you’re handling old corrugated cartons (OCC), office paper, magazines, or packaging scrap, you need a solution that turns disorganized waste into compact, valuable bales.

That’s exactly what a horizontal hydraulic baler does — and the fully automatic models take it to the next level.

What Is a Fully Automatic Horizontal Hydraulic Baler?

The fully automatic horizontal hydraulic baler is specially designed for loose materials such as waste paper, woven bags, plastic films, coke bottles, etc. It can easily compress them into blocks, saving costs and simplifying transportation. Its fully automatic unmanned operation mode is particularly suitable for environments with large amounts of materials. The compressed materials are easier to store and stack, effectively reducing transportation costs. It features:

- Automatic material feeding via conveyor

- Hydraulic compression to compact paper waste

- Automatic strapping using either PP belt or iron wire

- Continuous operation, ideal for high-volume users

This baler design is built for facilities that need to process large amounts of waste paper efficiently while minimizing labor and maximizing automation.

Solution: Hydraulic Balers’ Compression Technology

1. High-Efficiency Compression

The fully automatic horizontal hydraulic baler compacts loose paper into uniform, high-density bales. This drastically reduces the storage volume and prevents paper from scattering. Whether you’re processing tons of paper per day or per hour, the hydraulic force delivers consistent results.

2. Automatic Strapping: PP Strapping or Iron Wire

One of the major advantages of your horizontal hydraulic baler is its automatic tying system, which supports both PP belts and iron wire. This feature:

- Eliminates manual bundling

- Saves labor costs and time

- Ensures tightly secured bales for easy stacking and shipping

Depending on material type and buyer preference, operators can switch between PP or wire strapping to meet market standards.

3. Labor Reduction & Increased Productivity

Manual baling is labor-intensive. With a fully automatic horizontal hydraulic baler, the entire process is streamlined:

- Feed paper automatically via conveyor

- Press and compress with minimal supervision

- Automatically tie bales and eject them

This reduces the need for operators and increases overall throughput.

Why Are Waste Paper Bales Still Loose?

Many businesses encounter a frustrating issue: even when the baler is running normally, the final waste paper bales come out loose and unstable. What causes this problem, and how can it be solved?

Let’s look at three critical factors that directly influence the compactness of paper bales, even when using a high-quality horizontal hydraulic baler:

1. Hydraulic Pressure Adjustment:

The hydraulic system is the core component of the baler and directly determines the compactness of the baling. Many users ignore the adjustment of hydraulic pressure, resulting in unsatisfactory baling results. The following are the key steps to adjust the hydraulic pressure:

- Check the amount of hydraulic oil: Insufficient hydraulic oil will cause unstable pressure. It is recommended to check the oil level regularly to ensure that it is within the standard range.

- Adjust the pressure valve: According to the type of waste paper and packaging requirements, appropriately increase the pressure valve (it is recommended to refer to the equipment manual to avoid overload operation).

- Test the pressure value: Use a pressure gauge to detect the actual pressure and ensure that it is consistent with the set value.

2. Selection of Strapping Materials:

The selection of strapping materials is often overlooked, but its impact on the compactness of the package should not be underestimated. The following are common strapping materials and their applicable scenarios:

- Polyester (PET) strapping: high strength, wear resistance, suitable for heavy waste paper bags.

- Polypropylene (PP) strapping: economical and suitable for light waste paper bags.

- Steel strapping: suitable for metal waste packaging, but the cost is higher.

Tips: When choosing strapping, pay attention to its width and thickness. Generally speaking, the wider and thicker the strapping tape is, the higher the tensile strength is and the better the packing effect is.

3. Equipment Maintenance:

Maintenance of the baler is the key to improving the packing density. Many faults (such as insufficient pressure and oil circuit blockage) will cause loose packing. Here are some important maintenance points:

- Regularly replace the hydraulic oil: Aging of the hydraulic oil will cause the pressure to drop. It is recommended to replace it every 6 months.

- Clean the oil circuit system: Clean the impurities in the oil circuit regularly to avoid blockage.

- Check the seals: Wear of the seals will cause hydraulic oil leakage, affecting the packing effect.

Applications in Various Industries

A horizontal hydraulic baler is not limited to paper waste alone. It can also process:

- Cardboard (OCC)

- Newspaper

- Office paper

- Magazines

- Packaging waste

Industries that benefit from horizontal hydraulic balers include:

- Printing and publishing companies

- Paper mills and converters

- Warehouses and distribution centers

- Retail and grocery chains

- Municipal waste and recycling facilities

Choosing the Right Horizontal Hydraulic Baler

When investing in a fully automatic horizontal hydraulic baler, consider:

- Daily or hourly waste paper volume

- Type of materials (e.g., OCC, mixed paper, kraft)

- Space available for installation

- Required bale size and weight

- Preferred strapping method: PET, PP, or iron wire

- Electrical capacity and local compliance standards

Selecting a reliable manufacturer who provides after-sales service and technical support is also crucial.

Looking for the right horizontal hydraulic baler for your operation?

Contact us today for customized solutions, pricing, and technical specifications.

-200x45.png)