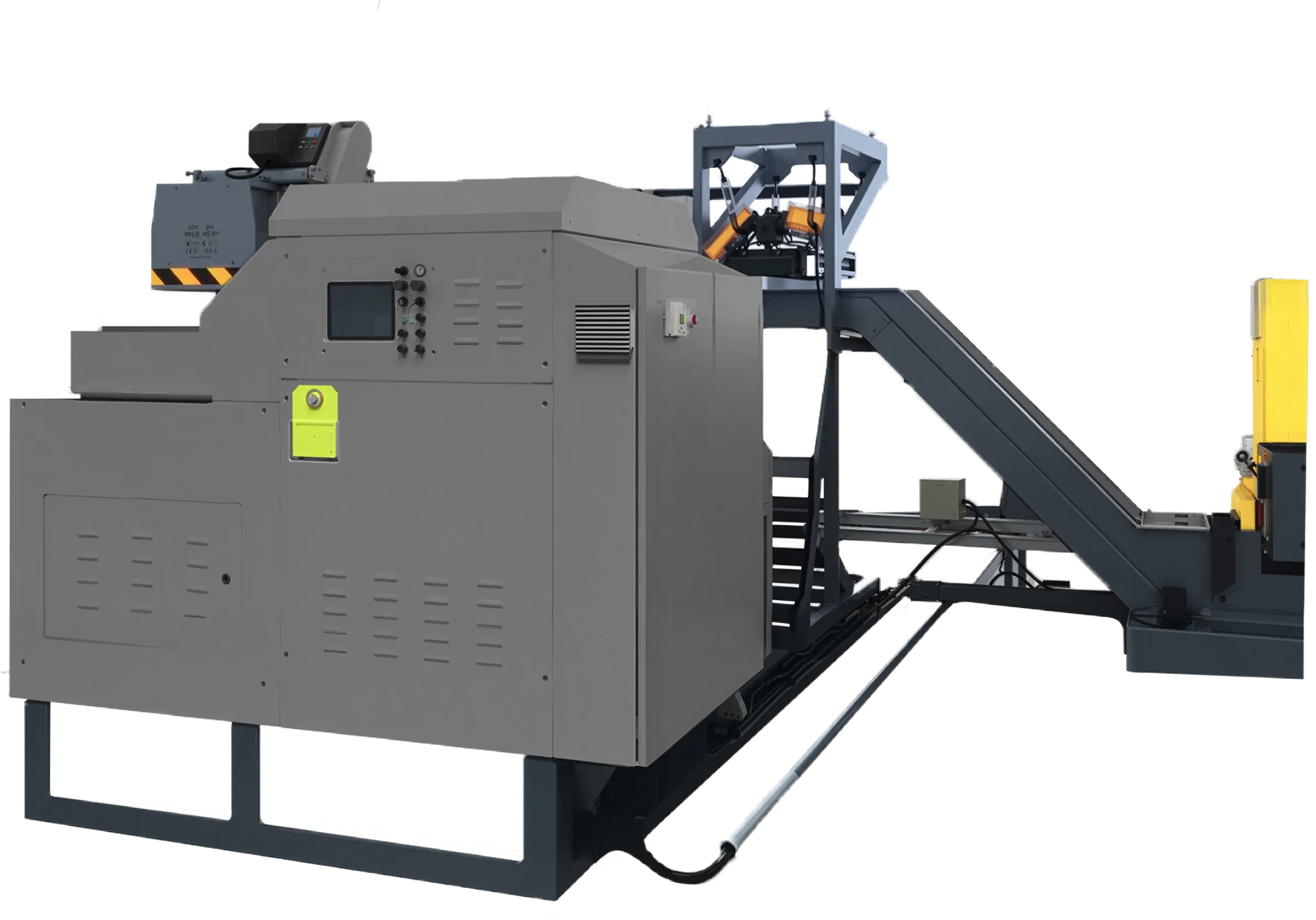

In modern metalworking industries, managing metal chips and turnings efficiently has become a key part of sustainable manufacturing. A swarf compactor, also known as a chip briquetting press machine, helps transform loose metal swarf into dense, manageable briquettes. This not only reduces storage and transportation costs but also allows for cleaner workshops and higher metal recycling value. Choosing the right swarf compactor, however, requires careful consideration of your production environment, material type, and operational goals.

This article provides an in-depth guide on how to select the most suitable swarf compactor for your factory.

1. Understand What a Swarf Compactor Does

A swarf compactor compresses loose metal chips—such as aluminum, steel, cast iron, brass, or copper—into solid cylindrical briquettes.

These briquettes are easier to handle, store, and transport. Moreover, compacting removes cutting fluids and oils from the chips, allowing the coolant to be recycled and reused.

In simple terms, a chip briquetting press machine helps you:

- Save valuable workshop space

- Recover and reuse coolant oil

- Reduce fire hazards from loose chips

- Improve recycling efficiency and cleanliness

Understanding how it works will help you evaluate technical parameters when choosing your equipment.

2. Identify Your Material Type and Volume

The first and most critical factor in selecting a swarf compactor is your material type. Different metals have different densities, oil content, and chip characteristics.

- Aluminum and brass chips are softer and easier to compress, producing uniform briquettes.

- Steel and stainless steel swarf require higher compaction force and wear-resistant components.

- Cast iron chips often contain graphite and oil, requiring efficient oil separation during compression.

Additionally, determine your daily or hourly chip volume.

For example:

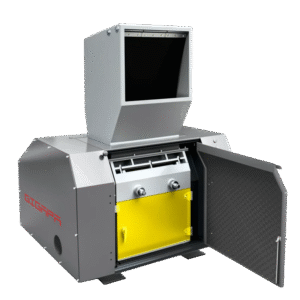

- Small workshops generating below 100 kg/hour can use a compact vertical swarf compactor.

- Medium-sized factories (100–500 kg/hour) may need a semi-automatic horizontal model.

- Large-scale production (500 kg/hour and above) requires a fully automatic chip briquetting press machine with continuous feeding and hydraulic compression.

Choosing based on actual chip output ensures efficiency without overinvesting in unnecessary capacity.

3. Evaluate the Compression Force and Briquette Density

The compression force directly affects the density and quality of the briquettes.

Typical hydraulic compactors range between 200–1000 kN.

A higher compression ratio leads to:

- Denser briquettes (less than 1/10 the original chip volume)

- Easier transportation and melting in furnaces

- Reduced residual oil content (as low as 2–5%)

However, too much force can overheat or damage the material.

The best swarf compactor should balance power, energy consumption, and briquette density.

4. Pay Attention to Oil Recovery System

Metal chips often contain cutting fluids or lubricants. A good swarf compactor should include an oil recovery system with separation filters and collection tanks.

Efficient oil recovery:

- Prevents coolant waste

- Reduces environmental pollution

- Saves cost on new cutting fluid

- Keeps the working area clean

For industries such as automotive parts or precision machining, this feature is critical for sustainability and compliance with environmental regulations.

5. Choose Between Manual, Semi-Automatic, and Fully Automatic Systems

Depending on your production scale and budget, swarf compactors come in three automation levels:

| Type | Features | Suitable for |

|---|---|---|

| Manual | Simple structure, requires operator feeding and discharge | Small workshops |

| Semi-Automatic | Hydraulic compression with partial automation | Medium production lines |

| Fully Automatic | Continuous feeding, oil separation, and briquette discharge | Large-scale metal recycling or machining factories |

A fully automatic chip briquetting press machine can operate continuously with minimal human intervention, ideal for companies seeking long-term ROI.

6. Check the Construction Quality and Material of the Machine

Since the swarf compactor operates under high pressure, durability is essential.

Key components to check:

- Hydraulic cylinder: must be made of high-strength alloy steel.

- Compression chamber: should have wear-resistant liners.

- PLC control system: ensures stable operation and accurate pressure monitoring.

Also, ensure the machine comes from a reliable manufacturer with proven case studies and after-sales service.

7. Consider Maintenance and Spare Parts Availability

Maintenance frequency affects production continuity.

Choose a machine with:

- Easy access to replaceable parts

- Local technical support or agent service

- Standardized components (such as hydraulic valves and seals)

For international buyers, it’s crucial to confirm that the swarf compactor supplier offers long-term spare part availability and online support.

8. Assess Energy Efficiency and Environmental Impact

Energy-efficient chip briquetting press machines reduce operating costs and carbon footprint.

Look for:

- Hydraulic systems with energy-saving pumps

- Smart pressure control that adjusts automatically

- Integrated oil-water separation system

In many regions, using eco-friendly equipment also qualifies for green manufacturing incentives or government subsidies.

9. Verify Certifications and Safety Standards

A professional swarf compactor should comply with international standards such as:

- CE Certification (Europe)

- ISO 9001 Quality Management

- Safety Guarding and Emergency Stop Systems

These certifications ensure machine reliability, operator safety, and legal compliance for import/export.

10. Calculate Total Cost of Ownership (TCO)

When purchasing industrial equipment, don’t focus only on the upfront price.

Consider:

- Installation and transportation costs

- Power consumption

- Maintenance expenses

- Machine lifespan

- Resale value

A high-quality swarf compactor may cost more initially but provides long-term savings through durability, reliability, and energy efficiency.

Conclusion

Choosing the right swarf compactor or chip briquetting press machine is a strategic investment that improves production efficiency, cleanliness, and sustainability. By understanding your material type, production volume, automation needs, and maintenance capabilities, you can select a machine that delivers the best balance of performance and cost.

In today’s competitive manufacturing environment, optimizing chip management is no longer optional—it’s essential for operational excellence and profitability. Investing in the right swarf compactor ensures your factory runs cleaner, greener, and more efficiently for years to come.

-200x45.png)