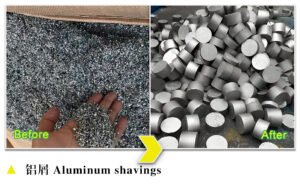

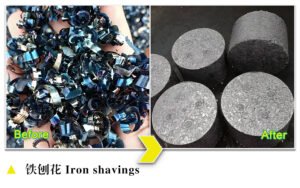

In the mechanical processing, metal casting, and other industries, the treatment of metal waste such as iron filings, aluminum filings, and copper filings has always been a difficult problem. The piles of scraps not only take up space but may also affect the production environment. How to efficiently recycle these metal scraps? The metal scrap briquetter came into being! It can compress the loose iron filings into high-density cakes, greatly reducing the volume, facilitating transportation and recycling, and at the same time increasing the economic value of the waste. Today, let’s take a deeper look at this industrial environmental protection tool!

What is Metal Scrap Briquetter

A metal scrap briquetter (also known as metal scrap briquetting machine) is a device that compresses metal scraps (such as iron scraps, aluminum scraps, copper scraps, steel scraps, etc.) into high-density cakes through high pressure.

Core advantages:

- Volume reduction of 70%-90%—loose scraps are pressed into compact cakes, saving storage and transportation costs.

- Increase recycling value—metal after briquetting is easier to melt and has a higher recovery rate.

- Environmentally friendly and efficient—reduce flying scraps, improve workshop environment, and meet green production requirements.

- Automated operation—hydraulic or mechanical pressing saves time and effort, and reduces labor costs to a certain extent.

Application Scenarios of Metal Scrap Briquetter

1. Mechanical processing industry

Lathes, milling machines, and CNC machining centers will produce a large amount of iron scraps and aluminum scraps, and the briquetting machine can quickly process them to avoid waste accumulation.

2. Foundries & Metal Smelters

Metal scraps after briquetting are easier to put into furnaces for smelting, reducing oxidation losses and improving recovery rates.

3. Scrap Recycling Station

After metal briquettes are pressed, they are easy to transport and sell, which increases the profit of scrap trading.

4. Automobile Manufacturing & Hardware Industry

Scrap generated by stamping and cutting can be directly compressed to reduce processing costs.

Working Principle of Metal Scrap Briquetter

- Feeding: Metal scraps are put into the hopper through a conveyor belt or manually.

- Pre-pressing: Initial compression to remove air and oil.

- High-pressure forming: The hydraulic system applies tens to hundreds of tons of pressure to press the scrap into high-density cakes.

- Discharging: The pressed metal cakes are automatically discharged for easy stacking and shipping.

How to Choose Metal Scrap Briquetter

- Processing capacity: Choose the appropriate tonnage (such as 50T, 100T, 200T, etc.) according to the average daily scrap volume.

- Applicable materials: Different metals such as iron scraps, aluminum scraps, copper scraps, etc. need to match the corresponding pressure.

- Automation degree: Manual, semi-automatic or fully automatic, select according to needs.

- Brand and after-sales: Choose a reliable manufacturer to ensure equipment stability and long-term maintenance support.

Maintenance and care

1. Daily maintenance

Cleaning equipment

- After each use, remove the residue (such as metal scraps, oil stains, dust) from the mold, roller, feeding system and other parts to avoid accumulation that affects the accuracy or corrodes the equipment.

- Clean the surface with a soft cloth or brush. Stubborn stains can be wiped with a neutral detergent and avoid using corrosive chemicals.

- Make sure the equipment is completely dry after cleaning to prevent rust.

Lubrication and maintenance

- Lubrication points: Regularly lubricate moving parts such as guides, bearings, chains, gears, etc., and use the lubricant specified in the equipment manual (such as lithium-based grease or anti-wear hydraulic oil).

- Hydraulic system: Check the hydraulic oil level, replace the oil regularly (it is recommended to replace every 6-12 months or according to the workload), and filter impurities.

- Pneumatic system: drain the water in the water separator and check whether the air pipe is leaking.

Tightening inspection

- Check whether the bolts, nuts, and mold fixings are loose, especially the high-frequency vibration parts (such as the punch head and transmission mechanism).

- Use a torque wrench to tighten according to the standard to avoid over-tightening and thread damage

2. Regular maintenance

Key component inspection

- Mold: Check for wear, cracks or deformation, and repair or replace in time; apply anti-rust oil when storing.

- Electrical system: Check the aging of the line, oxidation of the relay contacts, and clean the dust in the electric control box.

- Transmission system: Check the tension of the belt/chain, adjust or replace the worn parts.

Hydraulic and pneumatic system

- Regularly replace the hydraulic oil filter element, check the sealing of the oil cylinder, and avoid oil leakage.

- Pneumatic system: Check whether the pressure reducing valve and cylinder action are normal.

Calibration and debugging

- Regularly check the accuracy of sensors such as pressure gauges and travel switches.

- Adjust the mold gap and pressure parameters to ensure consistent cake thickness.

The metal scrap briquetter is not only a powerful assistant for scrap disposal, but also an important equipment for enterprises to reduce costs, increase efficiency and achieve green production. Whether it is a machining plant, a foundry, or a scrap recycler, it can help you improve efficiency and create higher value! Is your factory facing the problem of metal scrap disposal? Welcome to consult professional metal scrap briquetter solutions!

-200x45.png)