The plastic scrap baler machine plays a crucial role in addressing one of the most pressing environmental challenges worldwide—plastic waste management. With the rapid growth of manufacturing, packaging, and consumer industries, the volume of plastic scrap generated every day continues to increase. For recycling plants, manufacturing factories, and waste management companies, efficiently compressing and handling this waste is essential to reduce storage space, lower transportation costs, and improve overall recycling efficiency.

A plastic scrap baler machine plays a critical role in plastic recycling systems by compressing loose plastic waste into dense, manageable bales. This process significantly reduces storage space, lowers transportation costs, and improves recycling efficiency.

In this comprehensive guide, we will explore what a plastic scrap baler machine is, how it works, its key features, applications, benefits, and how to choose the right baler for your recycling needs.

What Is a Plastic Scrap Baler Machine?

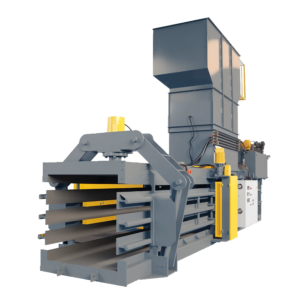

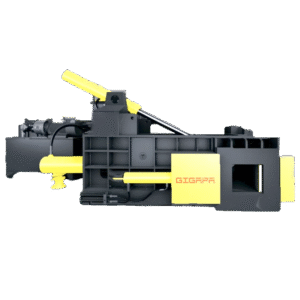

A plastic scrap baler machine is an industrial hydraulic machine designed to compress plastic waste materials into compact bales. These bales are easier to store, transport, and process in downstream recycling operations.

Plastic scrap materials typically include:

- PET bottles

- HDPE and LDPE plastics

- Plastic films and bags

- Injection moulding scrap

- Plastic containers and packaging waste

- Industrial plastic scraps

By converting loose plastic scrap into dense bales, recycling companies can optimize logistics and increase operational efficiency.

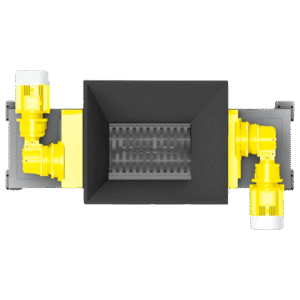

How Does a Plastic Scrap Baler Machine Work?

A plastic scrap baler uses a hydraulic compression system to apply high pressure to plastic waste. The basic working process includes:

- Material Feeding: Plastic scrap is fed into the baler chamber manually or through a conveyor system.

- Hydraulic Compression: A powerful hydraulic cylinder compresses the plastic scrap into a dense block. Multiple compression cycles ensure high bale density.

- Bale Tying: Automatic or manual tying systems secure the compressed bale using steel wire or PET strapping.

- Bale Discharge: The finished bale is ejected automatically or manually, ready for storage or transport.

This process significantly reduces the volume of plastic waste, making recycling operations more efficient and cost-effective.

Key Features of a Plastic Scrap Baler Machine

- Powerful Hydraulic System: High-pressure hydraulic cylinders ensure strong compression, producing dense and uniform bales.

- Heavy-Duty Steel Structure: Industrial-grade steel frames provide durability and long-term stability, even under continuous operation.

- PLC Intelligent Control: Modern balers use PLC systems for automated operation, fault detection, and safety control.

- Automatic Bale Tying System: Fully automatic balers use wire tying machines, reducing labor costs and improving efficiency

- Energy-Efficient Design: Optimised hydraulic circuits and servo systems reduce power consumption.

- Safety Protection System: Emergency stop buttons, door interlocks, and overload protection ensure operator safety.

Applications of Plastic Scrap Baler Machines

Plastic scrap balers are widely used across various industries:

- Plastic Recycling PlantsRecycling facilities use balers to compress plastic bottles, films, and containers before shredding or granulating.

- Manufacturing FactoriesInjection molding and extrusion factories generate large volumes of plastic scrap that must be compacted for recycling or disposal.

- Waste Management CompaniesMunicipal waste processing facilities use balers to handle plastic waste efficiently.

- Logistics and Packaging IndustriesWarehouses and distribution centers use balers to manage plastic packaging waste.

- E-Waste RecyclingPlastic casings from electronic waste are baled before further processing.

Benefits of Using a Plastic Scrap Baler Machine

- Volume Reduction: Baling reduces plastic waste volume by up to 80–90%, optimizing storage and transport.

- Lower Transportation Costs: Dense bales allow more material to be transported per truckload, significantly reducing logistics expenses.

- Improved Recycling Efficiency: Uniform bales simplify feeding into shredders and granulators, improving processing efficiency.

- Increased Workplace Safety: Compressed bales reduce loose waste, improving workplace cleanliness and safety.

- Higher Profitability: Compact bales have higher market value and are easier to sell to recycling buyers.

Key Technical Parameters of Plastic Scrap Baler Machines

When selecting a plastic scrap baler, consider the following technical parameters:

- Compression Force: 50–200 tons or more

- Bale Size: Customizable (e.g., 1100 × 1100 × 1200 mm)

- Bale Weight: 300–1500 kg, depending on material

- Power Requirement: 15–75 kW

- Throughput Capacity: 1–20 tons/hour

- Automation Level: Manual, semi-automatic, fully automatic

These parameters should be chosen based on material type, production volume, and recycling workflow.

How to Choose the Right Plastic Scrap Baler Machine?

- Material Type: Different plastics have different compression characteristics. PET bottles require higher compression than plastic films.

- Throughput Requirement: Estimate daily or hourly processing capacity to select the appropriate baler model.

- Automation Level: Fully automatic balers reduce labor costs but require a higher initial investment.

- Space Availability: Vertical balers are suitable for limited space, while horizontal balers require larger installation areas.

- Budget Considerations: Consider the total cost of ownership, including energy consumption, maintenance, and labor savings.

- Manufacturer Support: Choose a reliable manufacturer that provides installation, training, and after-sales service.

Plastic Scrap Baler vs. Plastic Shredder: What’s the Difference?

Many recycling facilities use both balers and shredders. Their functions are different:

- Plastic Scrap Baler: Compresses loose plastic into dense bales for storage and transport.

- Plastic Shredder: Reduces plastic size into small flakes for further recycling processes.

Balers are often used before shredders to optimize material handling.

Maintenance and Safety Tips

- Regular Hydraulic System Inspection: Check oil levels, seals, and hoses to prevent leaks and ensure stable pressure.

- Lubrication: Lubricate moving parts regularly to reduce wear.

- Electrical System Check: Inspect PLC, sensors, and wiring to avoid downtime.

- Operator Training: Ensure operators are trained in safety procedures and emergency operations.

- Spare Parts Management: Keep critical spare parts in stock to minimize downtime.

Future Trends in Plastic Scrap Baling Technology

The recycling industry is evolving rapidly, and baler technology is advancing with new features:

- Smart PLC and IoT Monitoring

- Energy-Saving Servo Hydraulic Systems

- Fully Automated Recycling Lines

- Robotic Bale Handling Systems

- Integration with Sorting and Shredding Systems

These innovations help recycling companies improve efficiency and reduce operational costs.

Conclusion

A plastic scrap baler machine is an essential piece of equipment for modern recycling and waste management operations. Compressing loose plastic waste into dense bales significantly improves storage efficiency, reduces transportation costs, and enhances recycling productivity.

Whether you operate a recycling plant, manufacturing factory, or waste management facility, investing in the right plastic scrap baler machine can deliver substantial economic and environmental benefits.

If you are looking for a reliable plastic scrap baler machine manufacturer, consider factors such as capacity, automation level, energy efficiency, and after-sales support to make the best decision.

-200x45.png)