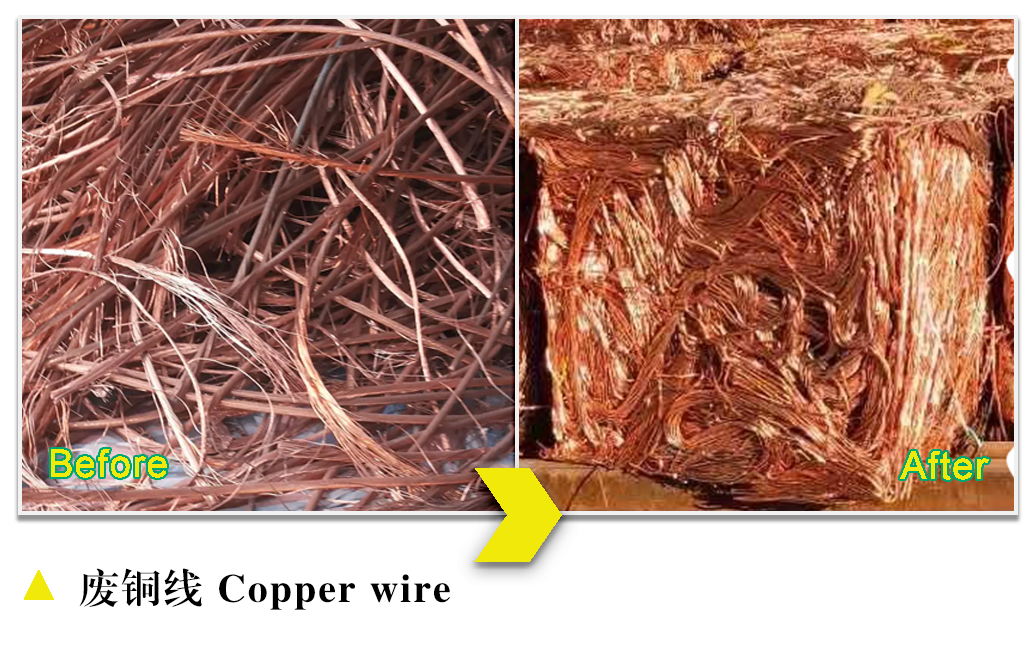

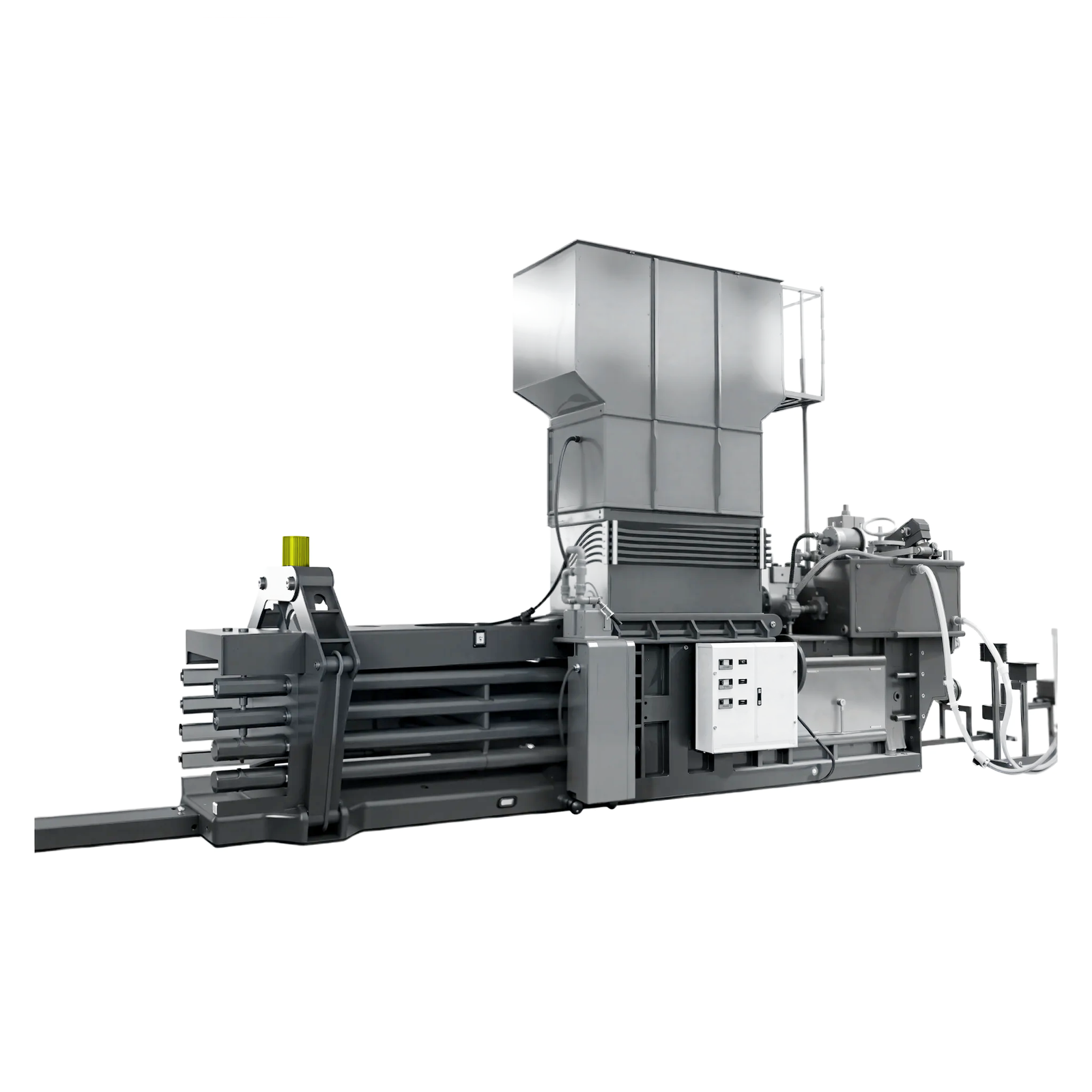

Equipment Introduction:

Continuous metal baling machines are also known as hopper-type briquetting presses, primarily used for compressing metal scrap into blocks. They can expel some liquid, increase bulk density, facilitate stacking, and recycle. They are particularly suitable for materials with a high original bulk density. By using a hopper for material storage, they allow for continuous feeding and compression, reducing downtime for loading and enhancing production efficiency. When combined with conveyors, they can easily integrate with existing production equipment to form an automated processing line. Therefore, they are widely used in situations where materials are difficult to compress, where a high degree of automation is required, and where they need to form a production line with other equipment.

Application Range:

| General Metal Scraps | Aluminum cans, scrap steel, scrap iron, waste aluminum, waste copper, waste color-coated steel tiles, construction waste rebars, waste aluminum profiles |

| Ferrous Metal Granules | Granulated stainless steel chips, granulated steel chips, granulated iron chips, stamping scraps |

| Non-Ferrous Metal Granules | Granulated aluminum chips, granulated titanium chips |

| Structural Metal Waste | Disassembled car bodies, household appliance shells, computer case shells; aluminum foil sorted from lithium battery electrode pieces |

| Manufacturing Byproducts | Granulated chips from refined plate production, thick aluminum sheets/aluminum scraps from rough machining |

| Miscellaneous Metal Waste | Silicon steel sheet scraps, oil filters, oil drums, paint cans, aluminum foil product scraps |

| Application Industries | Metal Recycling, Automobile Manufacturing, Aerospace, Resource Regeneration, Metal Smelting, Other Industries |

Model Parameters:

| Model | GFB-C2510 | GFB-C3016 | GFB-C3520 | GFB-C4020 |

| Packaging Size (W×H)(mm) | 250×250 | 300×300 | 350×350 | 400×400 |

| Main Cylinder Pressure (T) | 100 | 160 | 200 | 250 |

| Sub-Cylinder Pressure (T) | 50×2 | 80×2 | 100×2 | 125×2 |

| Hydraulic Power (kW) | 22 | 45 | 30×2 | 45×2 |

| Host Size (L×W×H)(mm) | 3150×3300×2150 | 3530×3700×2150 | 3950×4130×2450 | 4500×4600×2450 |

| Overall Weight (kg) | Approx. 6300 | Approx. 7500 | Approx. 9000 | Approx. 11100 |

The above models are standard universal models. If you require other models, please contact our staff, and we can also provide customized services according to your needs.

Technical Highlights:

1. Infinite Strength

Utilizing a dual-sided cylinder compression to increase compression pressure and enhance the compression effect.

2. Waste Liquid Channel

Unique channels for liquids and debris ensure a clean and tidy ground surface.

3. Intelligent Control

Engineers have crafted a smart PLC program that easily achieves seamless integration with other equipment.

Working Principle

1. Loading Through the Hopper

Metal scrap is first loaded into the machine’s hopper either manually or via a conveyor belt. The hopper provides a storage space for the metal scrap and ensures that the scrap enters the compression chamber evenly. The hopper’s size may vary depending on the model, determining the amount of metal scrap it can hold at one time.

2. Compression Process

- Compression Chamber: Once the metal scrap enters the compression chamber, the hydraulic system is activated to push a piston that compresses the material into a compact block. The compression force is applied through a hydraulic cylinder to compress the scrap into a dense block.

- Hydraulic System: The hydraulic system is the core of the compression process. High-pressure hydraulic oil drives the piston, which forces the metal scrap to compact into a tightly packed block. During this process, the scrap is compressed to a high density, usually resulting in blocks that are rectangular or cylindrical in shape.

- Automatic Control: Most continuous metal balers are equipped with an automatic control system. The system controls the compression force and time based on the set bale size, ensuring consistency in density and size for each bale.

3. Baling and Ejection

Once the metal scrap has been compressed to the desired volume and density, the machine activates the tying system. The tying system typically uses steel wire or plastic straps to bind the compressed block into shape. After tying, the bale is ejected from the machine.

- Tying System: Steel wire or plastic straps are used by a mechanical or hydraulic arm to secure the bale, ensuring it stays intact during transportation and storage.

- Ejection System: After the bale is tied, it is automatically pushed out of the machine via a hydraulic or mechanical ejection system, ready for further processing, transportation, or sale.

4. Continuous Operation and Automation

The “continuous” nature of the continuous metal baler allows it to operate without interruption. With an automated control system, the machine can continuously carry out the functions of loading, compressing, tying, and ejecting, greatly enhancing production efficiency.

Main Components

- Hydraulic System: Provides power to the machine, using hydraulic cylinders and pistons to compress the scrap metal.

- Hopper: The area where the metal scrap is stored and loaded into the machine.

- Compression Chamber: The area where the metal scrap is compacted under high pressure to form a block.

- Tying System: Binds the compacted block with steel wire or plastic straps to prevent it from loosening.

- Ejection Device: Pushes the tied block out of the machine for further handling.

-200x45.png)