Equipment Introduction:

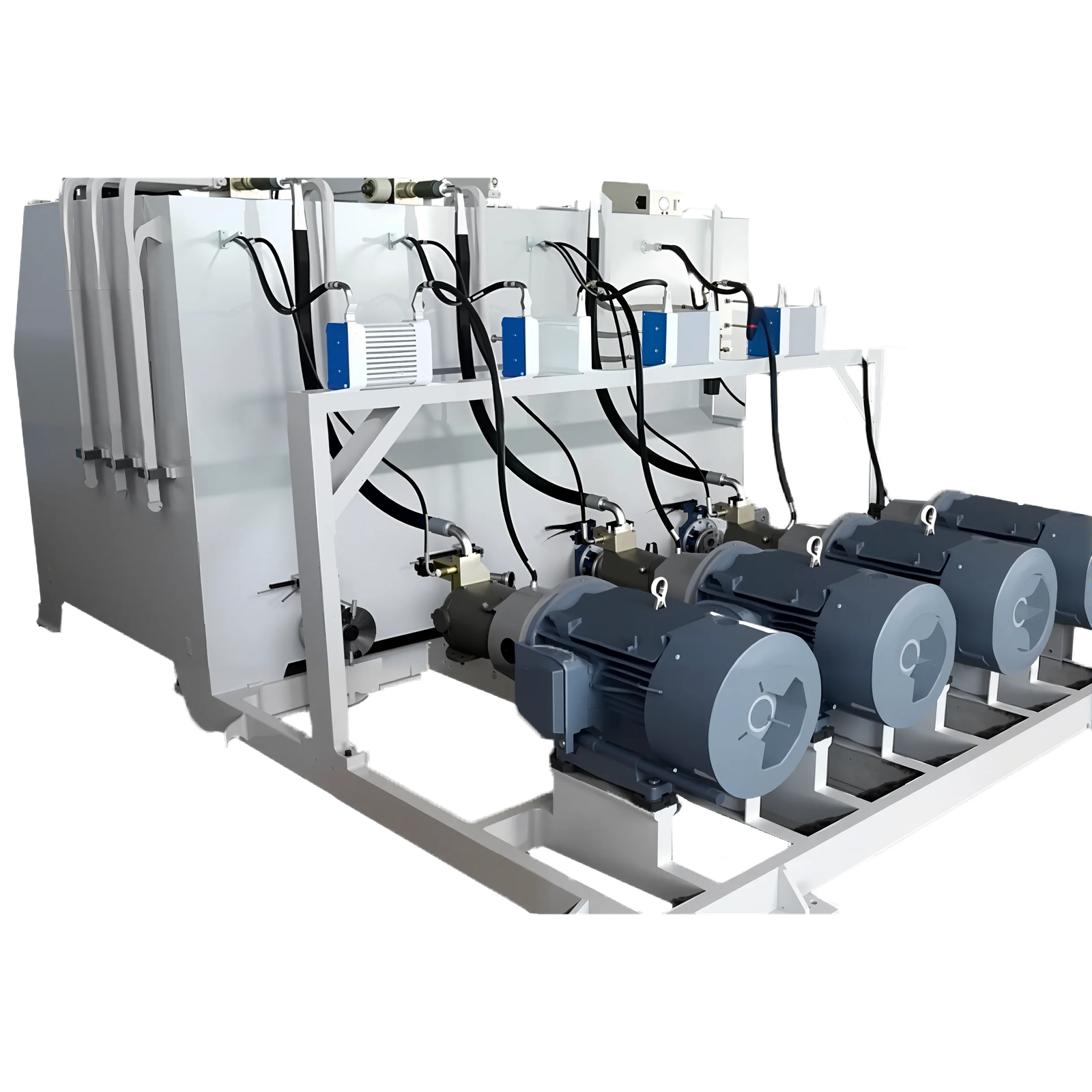

The fully automatic horizontal baling machine consists of a casing, a hydraulic station, hydraulic cylinders, a pressure head, a wire threading mechanism, a wire twisting mechanism, and a necking mechanism, among other components. The main cylinder drives the pressure head to compress the material, while the necking mechanism provides resistance for the package block to pass through. The wire threading mechanism and the wire twisting mechanism work together to tie up the package block. The entire compression and binding process of the package block is controlled by a PLC, eliminating the need for manual intervention, and the high level of automation means it is not only efficient but also saves on labor costs. Consequently, it is widely used in situations where a large volume of processing is required and processing speed needs to be fast.

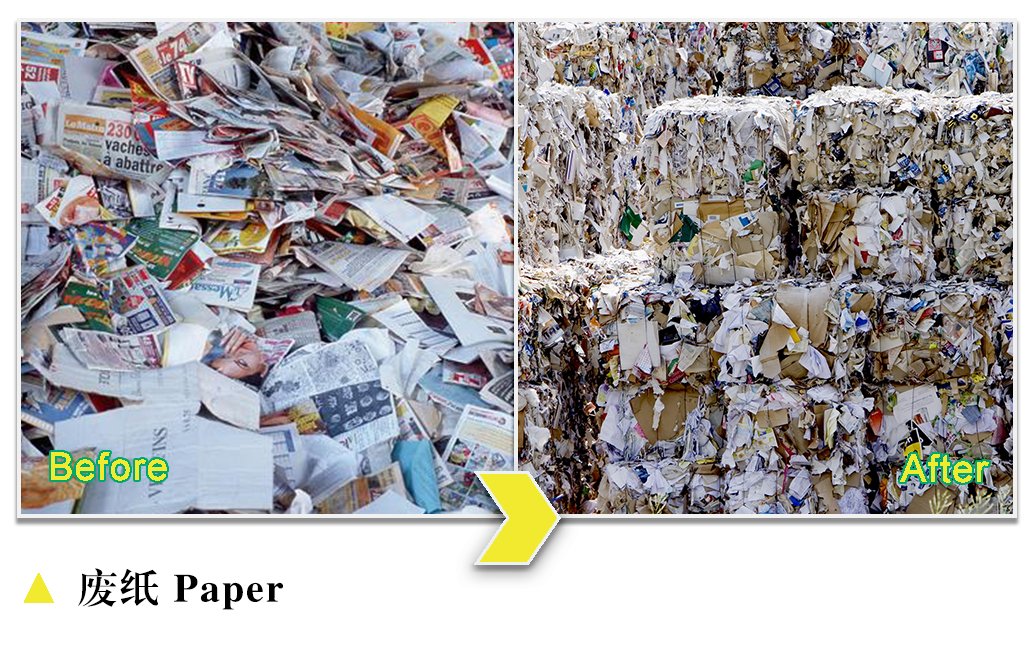

Application Range:

| Paper | Cardboard boxes, paper boxes, advertising paper, various paper mill and printing factory scraps, etc. |

| Plastics | Plastic bags, plastic packaging, plastic bottles, beverage bottles, ground film, plastic film, woven bags, etc. |

| Fabric and leather | Leather scraps, textile factory scraps, garment factory scraps, carpets, clothing, curtains, plush toys, etc. |

| Plants | Various straws, tree branches, etc. |

| Metals | Aluminum cans, etc. |

| Others | Household garbage, sponges, rubber strips, industrial waste, etc. |

Model Parameters:

| Model | GSB-F0707 | GSB-F1107 | GSB-F1111 | GSB-F1112 |

| Packaging size (W×H×U)(mm) | 720×720×(500-1500) | 1100×750×(500-1500) | 1100×1100×(500-1800) | 1100×1250×(500-1800) |

| Number of binding passes (PCs) | 4 | 4 | 5 | 5 |

| Main cylinder pressure (T) | 63 | 63 | 100 | 112 |

| Hydraulic power (kW) | 22 | 22 | 45 | 55 |

| Host size (L×W×H)(mm) | 6780×3000×3600 | 6880×3800×3600 | 8560×3910×4500 | 9260×4120×4850 |

| Overall weight (kg) | Approx 6800 | Approx 9100 | Approx 18600 | Approx 21300 |

The above models are standard universal models. If you require other models, please contact our staff, and we can also provide customized services according to your needs.

Technical Highlights:

1. High intelligence

The rigorous and reliable PLC control program, combined with sensors, improves the efficiency and effectiveness of packaging, reducing operational difficulty.

2. Good stability

The equipped material cutting device effectively cuts the risk of downtime caused by material jamming.

3. High reliability

The overall structure adopts a design with a large safety factor, preventing permanent deformation or cracking.

FAQ

1. Do you offer customized solutions?

We can provide customized equipment solutions based on your specific needs, including equipment size, functional configuration, and level of automation.

2. Can additional features or accessories be added to the equipment?

We offer a variety of optional accessories, allowing you to add features as needed, such as automatic feeding and hydraulic system upgrades.

3. How long will the product last?

Our equipment is constructed of high-strength steel and is designed to last 10-20 years. With regular maintenance, it can operate reliably.

4. Is the equipment complex to operate?

Our equipment features an automated control system with a simple, easy-to-understand interface, allowing operators to operate with minimal training.

5. Is the equipment safe during operation?

The equipment is equipped with multiple safety features, including automatic shutdown and overload protection, to ensure safe operation.

6. Do you offer volume discounts or customized quotes?

We offer volume discounts for bulk purchases. Additionally, if you require customized equipment, we can provide a customized quote based on your needs.

7. What payment methods do we accept?

We accept TT (Telegraphic Transfer) as a payment method. Upon receiving our official quotation, customers are required to pay a deposit via bank transfer in accordance with the contract terms.

8. Do we accept FOB delivery terms?

Yes, we offer FOB delivery terms.

Working Principle

GIGAPA fully automatic horizontal baling machine adopts an electromechanical and hydraulic integrated design, and realizes fully automatic strapping operation through intelligent control system. Its work process can be divided into four key stages:

Feeding compression stage

After the material enters the baling chamber through the conveyor belt or manually, the main hydraulic cylinder drives the pressure head to compress the waste horizontally. The unique necking device works synchronously to form a standard bale size during the compression process.

Bundling preparation stage

When the bale reaches the preset density, the intelligent wire threading mechanism automatically passes the baling wire through the bottom of the bale. High-precision sensors monitor the wire threading position in real time to ensure the accuracy of strapping.

Automatic strapping stage

After receiving the PLC instruction, the wire twisting mechanism quickly completes the actions of tightening and cutting the wire. The double locking technology is used to ensure that the strapping firmness meets the transportation requirements.

Discharging cycle stage

The bundled bales are automatically discharged by the ejection mechanism, and the system immediately enters the next working cycle. The whole machine is equipped with a fault self-diagnosis system, which can monitor the operating status of each component in real time.

The horizontal baling machine adopts industrial-grade PLC control and has the following technical advantages:

- Compression force can reach 200-500 tons (depending on the model)

- Packaging efficiency 6-12 packs/hour

- Wire bundling tensile strength ≥800N

- Optional automatic weighing system

- Support remote monitoring function

Horizontal Baler vs. Vertical Baler: How to Choose?

In the waste recycling and baling industry, horizontal baling machines and vertical balers are common equipment. Both effectively compress and baler waste, but they differ significantly in structure, application scenarios, and processing capacity.

1. Horizontal Baler

- High processing capacity: Suitable for medium to large production needs, with continuous feeding and automated baling.

- High degree of automation: Most models can be equipped with a conveyor belt for fully automated baling, saving labor.

- Wide application: Suitable for large or high-density materials such as metal, cardboard, plastic bottles, and fiber.

- Large footprint: Typically requires a fixed installation, making it more suitable for industrial environments such as recycling stations and waste treatment plants.

2. Vertical Baler

- Compact structure: Small size, easy installation, and minimal space requirements.

- Simple operation: Manual loading and baling are required, making it suitable for small businesses or those with low production volumes.

- High cost-effectiveness: Low equipment investment cost and easy maintenance. Applicable Materials: Ideal for cardboard, plastic film, lightweight waste, and more.

3. How to Choose?

- If you’re a large-scale scrap recycling plant or metal processing company with high production and efficiency requirements, a horizontal baler is recommended.

- If you’re a small factory, warehouse, or supermarket primarily processing lightweight packaging waste, a vertical baler is more economical and practical.

👉 Whether you choose a horizontal baling machine or vertical baler, we offer customized solutions tailored to your needs, helping you achieve more efficient and environmentally friendly waste management.

-200x45.png)