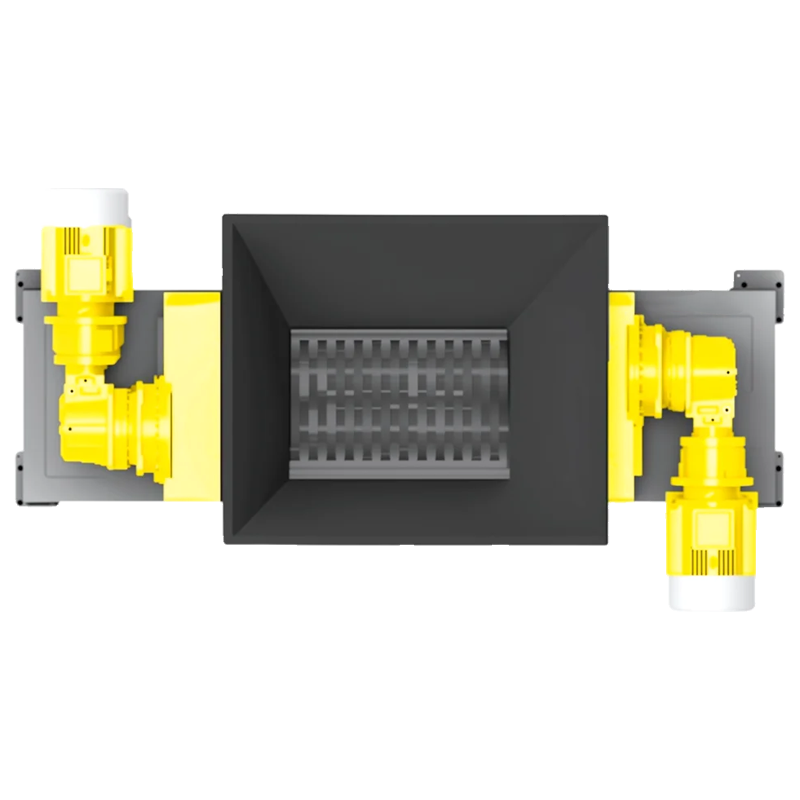

Equipment Introduction:

The fully automatic horizontal cotton baler consists of a housing, hydraulic station, hydraulic cylinder, pressure head, and binding mechanism. The hydraulic pressure provided by the hydraulic station drives the main cylinder to compress the material using the pressure head. After compression, the bale is ejected by the ejection hydraulic cylinder, and the binding mechanism binds the bale. The entire bale compression and binding process is controlled by a PLC. The binding mechanism automatically completes the feeding, binding, and tightening processes without manual intervention, resulting in a high degree of automation. This makes it not only highly efficient but also saves labor costs. Therefore, it is widely used in applications requiring large throughput and high processing speed, such as cotton mills, textile mills, and waste treatment plants.

Parameter Selection:

| Model | GSB-P0505 | GSB-P0606 |

| Bale Size (W×H×L) (mm) | 500×500×500 | 600×600×750 |

| Number of Binding Wires (PCS) | 2-5 | 3-5 |

| Main Cylinder Pressure (T) | 40 | 50 |

| Hydraulic Power (kW) | 7.5 | 15 |

| Machine Size (W×H×L) (mm) | 3990×3960×2220 | 5980×4680×2430 |

| Machine Weight (Kg) | 2600 | 4500 |

Applications:

Cotton, cotton linters, chemical fibers, hemp, wool, grass, medicinal materials, and recycled materials (such as waste paper and plastics) and other lightweight, loose materials.

Technical Highlights:

- High Reliability: The entire machine structure adopts a high safety factor design, preventing permanent deformation or cracking.

- High Intelligence: A rigorous and reliable PLC control program, combined with sensors, improves packaging efficiency and effectiveness.

- Good Stability: The equipped material cutting device effectively reduces the risk of downtime caused by material jamming.

Effect Comparison:

Advantages of Fully Automatic Horizontal Cotton Baler:

High Automation & Productivity: Eliminates manual feeding and bale ejection via conveyor belt integration, enabling continuous operation. This reduces labor costs and boosts throughput, ideal for large-scale cotton processing facilities handling high volumes daily.

Superior Bale Density & Uniformity: Horizontal compression design delivers consistent, high-pressure compaction, producing dense, uniform bales. Denser bales minimize storage space requirements and reduce transportation costs by maximizing load capacity per shipment.

Space-Efficient Workflow: Despite larger overall size, its horizontal layout integrates seamlessly with production lines (e.g., cotton ginning or textile waste processing), optimizing floor space usage compared to disjointed manual or semi-automatic setups.

Operational Convenience & Safety: Automated controls (e.g., PLC systems) simplify operation, while built-in safety features (emergency stops, interlocks) ensure compliance with workplace safety standards. Reduced manual intervention also lowers accident risks.

Cost Savings Over Time: Lower labor costs, reduced logistics expenses, and minimal downtime (due to reliable automation) contribute to a lower total cost of ownership, making it a long-term cost-effective investment for high-volume operations.

-200x45.png)