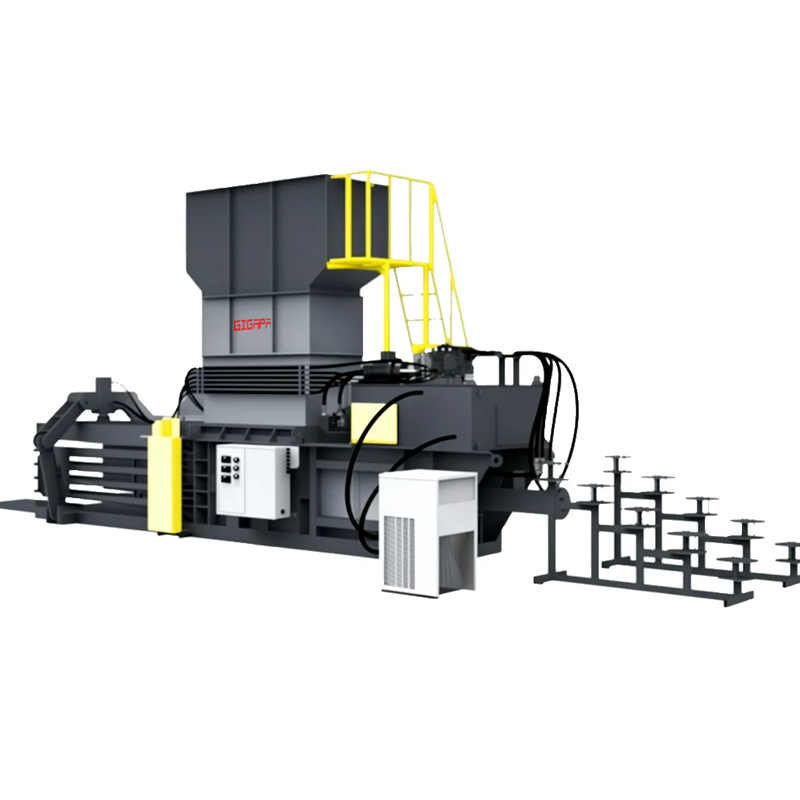

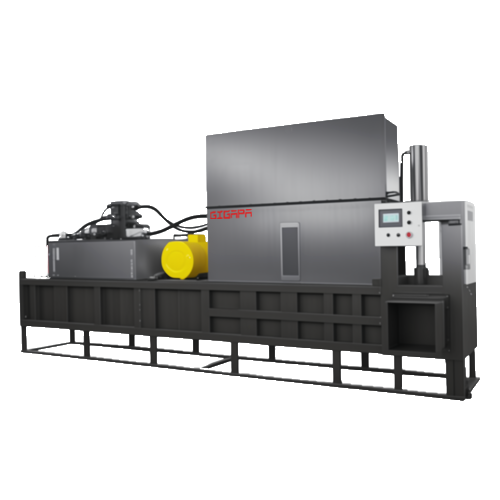

The Fully Automatic Strapping Baler (Iron Wire) is a heavy-duty and intelligent waste management machine designed to streamline the recycling process by compressing large volumes of material into dense, easy-to-handle bales secured with durable iron wire. Built for high-performance industrial applications, this baler delivers automation, speed, and safety—making it an ideal solution for modern waste processing and recycling centers, logistics hubs, and manufacturing facilities.

As waste volumes increase across industries, businesses need efficient, reliable solutions to manage and transport recyclable materials. This baler meets that need by offering a fully automated baling and strapping system, significantly reducing labor costs and improving operational efficiency.

Key Features

Fully Automatic Operation

From feeding to compression to bale ejection and strapping, all processes are controlled automatically via a user-friendly PLC system. Operators simply set the parameters and monitor performance through a touchscreen interface, allowing the baler to function with minimal human intervention. This ensures consistent output and greatly increases productivity.

Strong Iron Wire Strapping System

Unlike balers that use plastic straps or twine, this model uses iron wire for strapping—offering superior strength and durability. This is especially important for heavy and rigid materials like cardboard, cartons, and compressed paper. The automatic wire tying system ensures each bale is tightly secured, stable during transport, and compliant with recycling facility requirements.

Heavy-Duty Construction

Constructed with high-grade wear-resistant steel, this baler is built for 24/7 industrial use. Its reinforced frame, hydraulic components, and wear-resistant liners are designed to withstand high-pressure operation without deformation or frequent maintenance. It also includes a powerful hydraulic system for strong and fast compaction.

Consistent Bale Output

The machine produces uniform, high-density bales with adjustable length and weight depending on the material and customer needs. This consistency improves space utilization in storage and during transport, resulting in lower logistical costs and more organized waste handling.

Safety & Control

Safety is a core feature of this baler. Emergency stop buttons, door interlocks, overload protection, and fault alarms are integrated to ensure operator safety and prevent machine damage. The intelligent control panel displays real-time operating data and system alerts for quick response and smooth operation.

Applications

The Fully Automatic Strapping Baler (Iron Wire) is widely used in a variety of industries, including:

- Recycling Centers – For compressing paper, cardboard, and mixed paper waste

- Packaging and Printing Plants – To manage waste generated from trimming and defective prints

- Paper Mills – For collecting and baling waste edge trimmings and scrap rolls

- Warehouses and Distribution Centers – For compacting used cartons and packaging materials

- Municipal Solid Waste Facilities – For handling dry waste before transport or incineration

It is suitable for handling:

- Old Corrugated Cartons (OCC)

- Waste Paper and Newspaper

- Paper Packaging Waste

- Light Textile Waste (with optional configurations)

Advantages for Your Business

- Reduced Labor Dependency: Full automation cuts down on manual operations, increasing throughput with fewer workers.

- Lower Transportation Costs: Denser bales mean fewer trips and more material per load.

- Enhanced Workplace Efficiency: Clean, compact storage improves overall plant organization and safety.

- Consistent Quality Output: Uniform bales with strong strapping reduce material loss during handling.

- Durability & Reliability: Built to last in tough industrial environments with minimal downtime.

Conclusion

The Fully Automatic Strapping Baler (Iron Wire) is not just a machine—it’s a smart investment in efficiency, sustainability, and cost reduction. Designed with industrial demands in mind, it provides robust performance, intelligent control, and reliable strapping power, allowing your business to manage recyclable materials more efficiently than ever before.

Contact us today to learn how this baler can fit into your waste management or recycling process. Custom models and OEM/ODM services are available for global distributors and enterprise clients.

-200x45.png)