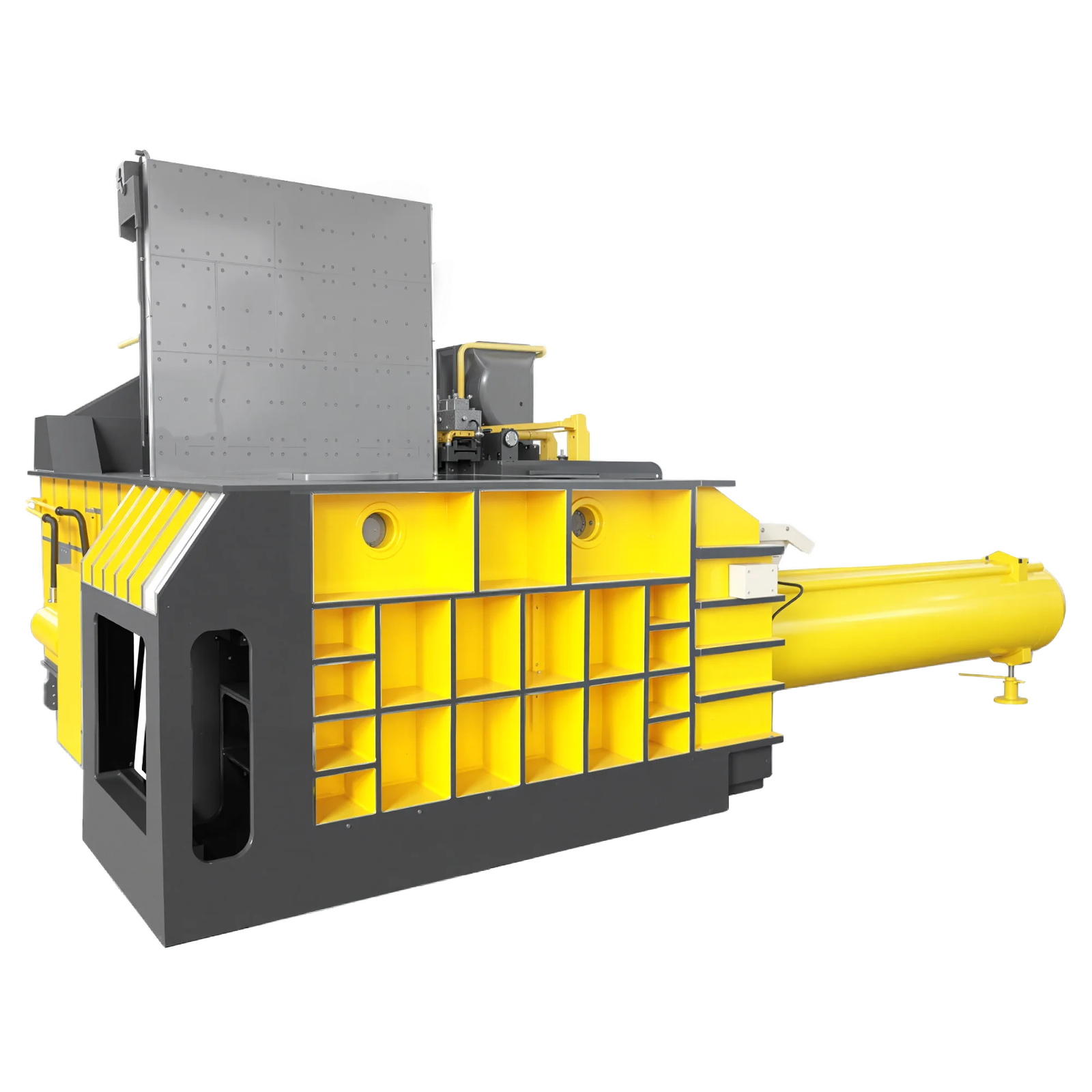

The hopper-type metal baler is a high-efficiency baling machine designed to handle large volumes of scrap metal with minimal labor. This heavy-duty baler is equipped with a hopper feeding system that allows continuous and automatic material loading, making it the ideal choice for recycling facilities, scrap yards, steel processing plants, and industrial manufacturers seeking to optimize their metal waste handling process.

Unlike traditional metal balers that require manual feeding, the hopper type baler uses a large hopper to automatically receive scrap metal from conveyors, forklifts, or cranes. Once the metal enters the chamber, the machine uses powerful hydraulic cylinders to compress the material into dense, manageable bales. This automated system significantly improves operational efficiency, reduces labor costs, and maximizes output.

Key Features of the Hopper Type Metal Baler:

- Automated Hopper Feeding: The integrated hopper allows for continuous feeding of metal scrap without manual intervention. This is particularly useful for facilities that generate high volumes of offcuts, trimmings, or shavings.

- Robust Hydraulic System: Equipped with high-pressure hydraulic cylinders, the baler compresses metal scraps into compact blocks with uniform density and shape.

- Heavy-Duty Frame: Constructed from wear-resistant steel, the frame offers superior strength and durability for long-term industrial use.

- PLC Control System: Easy-to-use interface with programmable logic controller (PLC) enables full automation and precise control of the baling process.

- Customizable Bale Size: Output bale dimensions can be customized to meet customer requirements, ensuring compatibility with transport and storage systems.

- Safety Design: Built-in safety interlocks and emergency stop features ensure operator protection during use.

Applications:

The hopper type metal baler is suitable for a wide range of scrap metal recycling operations, including but not limited to:

- Steel mills

- Non-ferrous metal recycling plants

- Aluminum extrusion factories

- Automotive part manufacturers

- Metal stamping workshops

- Machining centers and tool manufacturing plants

It can process materials such as:

- Aluminum scraps

- Copper wires and pipes

- Steel trimmings

- Stainless steel scraps

- Iron shavings

- Alloy metal pieces

By turning loose metal waste into high-density bales, this machine helps businesses save on transportation and storage costs while improving scrap value when selling to smelters or metal processors.

Advantages of Using Our Hopper Type Metal Baler:

- Labor Saving: Automatic feeding means fewer workers are required to manage the baling process, freeing up manpower for other tasks.

- Time Efficiency: Faster operation and continuous feed design significantly boost productivity, allowing more scrap to be processed in less time.

- Space Saving: Compressed bales take up significantly less space than loose metal, optimizing warehouse and container storage.

- Higher Resale Value: Dense, uniform bales are easier to handle and more valuable in the recycling market.

- Environmental Compliance: Helps meet environmental protection standards by promoting sustainable waste management and recycling.

Why Choose Our Hopper Type Metal Baler?

We have years of experience designing and manufacturing baling equipment for industrial and commercial applications. Our hopper type metal balers are engineered with precision, using high-quality materials and reliable components to ensure stable performance in demanding environments.

We also offer customization services to fit your production layout and recycling needs, including adjustments to hopper size, bale dimensions, and motor power. Comprehensive technical support, installation guidance, and after-sales service are provided to guarantee customer satisfaction.

Conclusion

The hopper-type metal baler is an essential piece of equipment for any business dealing with large volumes of metal scrap. With its automated feeding, powerful hydraulic compression, and heavy-duty design, this machine offers unmatched efficiency and reliability. Whether you’re processing aluminum, copper, or steel waste, our baler helps you reduce costs, streamline operations, and increase profitability.

-200x45.png)