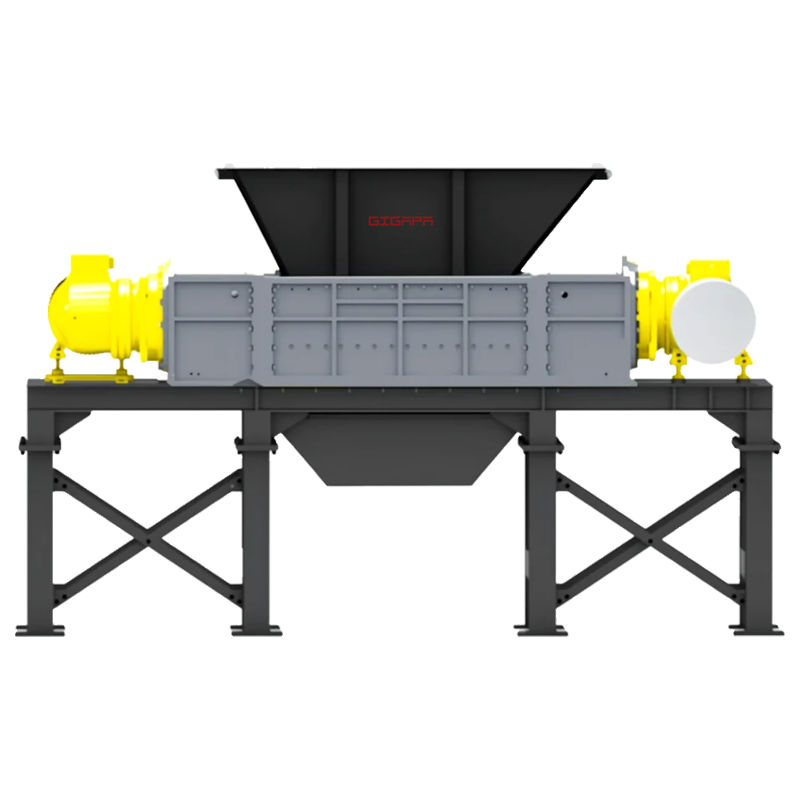

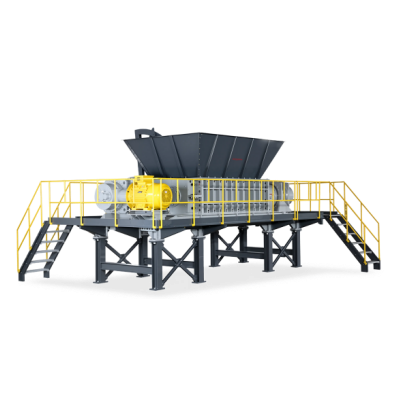

Equipment Introduction:

A single-shaft crusher, also known as a single-shaft granulator. The high-speed rotating blades of the single-shaft crusher continuously cut against the stationary blades until the material size is reduced enough to pass through the smaller aperture of the screen mesh. Due to its high rotational speed and small screen mesh size, it is typically used as a secondary crushing method. The smaller and uniform granules are beneficial for the operation of subsequent equipment such as granulators. The use of an air discharge device can effectively solve the problem of large space occupied by conveyors, and the final discharge position is more flexible. Because of these advantages, the single-shaft crusher is widely used in the recycling industry of resources that require high particle quality.

Application Range:

| Plastics | Injection molding, extrusion, blow molding, and other general plastics; traffic cones, small appliance shells, beverage bottles, woven bags, and other plastic products. |

| Wood | Waste wood, wood scraps, wood molds, wood pallets, wood doors, wood tables, wood chairs, etc. |

| Rubber | Tire rubber, recycled rubber, sealing strips, etc. |

| Paper | Document paper, wrapping paper, cardboard, books, etc. |

| Fabric and Leather | Leather scraps, synthetic fabrics, carpets, clothing, curtains, etc. |

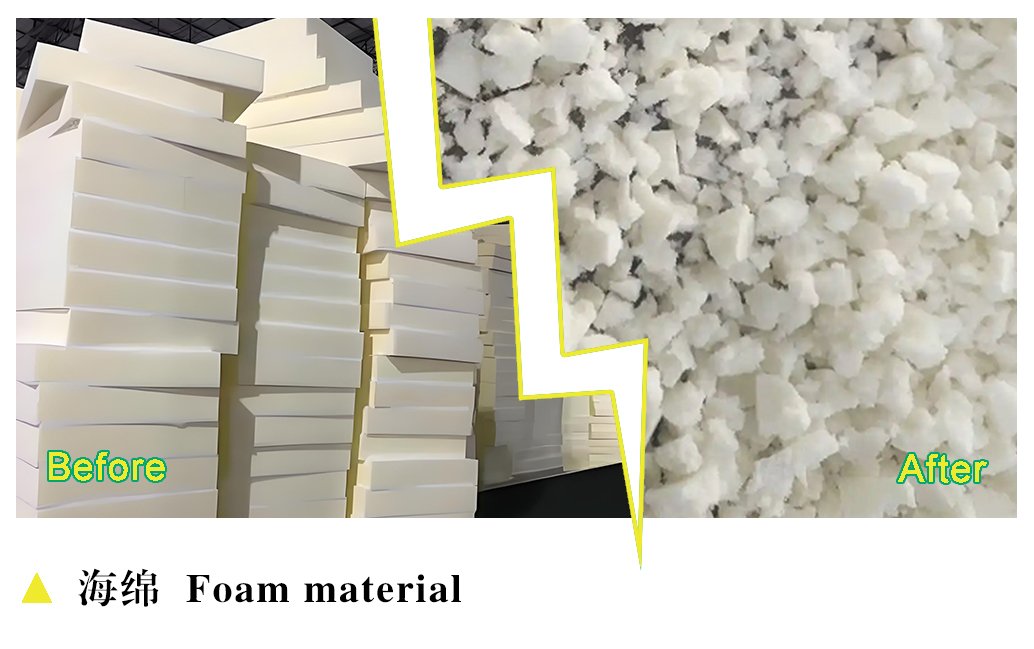

| Others | Circuit boards, wires, cables, sponge, foam, latex, fiberglass, etc. |

Model parameters:

| Model | GSG-M806 | GSG-M808 | GSG-M408 | GSG-M508 | GSG-M512 | GSG-M612 |

| Swing diameter (mm) | φ320 | φ320 | φ420 | φ520 | φ520 | φ660 |

| Roller length (mm) | 600 | 800 | 800 | 800 | 1200 | 1200 |

| Mesh aperture (mm) | φ12 | φ12 | φ12 | φ12 | φ12 | φ12 |

| Motor power (kW) | 22 | 30 | 37 | 45 | 75 | 90 |

| Dimensions (L•W•H)(mm) | 1400×1180×2220 | 1400×1380×2220 | 1580×1450×2310 | 2170×1780×3100 | 2170×2180×3100 | 2490×2280×3350 |

| Overall weight (kg) | Approx 1500 | Approx 1800 | Approx 3100 | Approx 4300 | Approx 5400 | Approx 7200 |

The above models are standard universal models. If you require other models, please contact our staff, and we can also provide customized services according to your needs.

Technical Highlights:

1. High reliability

High safety factor high-speed bearings are used, making the bearings more stable and long-lasting.

2. Good economy

Both the moving and fixed blades can be ground multiple times, effectively reducing the cost of wearing parts.

3. Excellent maintainability

The split box design is equipped with an opening and closing mechanism, making maintenance simple, efficient, and safe.

Working Principle

1. Material Feeding

- Material Input: The material is fed into the crushing chamber of the crusher through an inlet. Depending on the design, materials can be manually or automatically fed into the machine using a conveyor or other devices.

- Applicable Materials: This crusher can handle a variety of materials such as plastics, rubber, e-waste, metals, wood, paper, etc.

2. Cutting and Shredding by Rotating Blades

- Rotating Blades: The Single Shaft Crusher is equipped with a main shaft that drives multiple strong blades. The main shaft is typically driven by an electric motor, causing the blades to rotate at high speeds.

- Shear Action: As the material enters the crushing chamber, the rotating blades come into contact with the material. The blades apply a cutting, tearing, and compressing force to break the material into smaller particles.

- Interaction Between Material and Blades: The material is pushed into the blade area, where the blades rapidly cut and crush it. The relative motion of the blades against the material creates strong cutting and shredding forces.

3. Crushing and Screening

- Crushing Process: As the material passes through the blades, it is quickly shredded and crushed. The crushed material then flows out of the chamber, either passing through a screen or undergoing further crushing for more fine processing.

- Screening Function: Some models of the Single Shaft Crusher are equipped with screens to control the size of the crushed material. The material must pass through the screen, and if the particle size meets the required specifications, it is expelled. If not, the material will re-enter the crushing chamber for further reduction.

4. Material Output

- Crushed Particles: The material is continuously shredded and crushed by the rotating blades and is ejected from the crusher through the outlet. Due to the high-speed cutting and shredding action, the resulting output is usually in the form of smaller, uniform particles.

- Particle Size: The final particle size depends on the blade design, material hardness, and operating conditions. If smaller particles are needed, the blade precision may be adjusted, or operational settings can be fine-tuned.

-200x45.png)