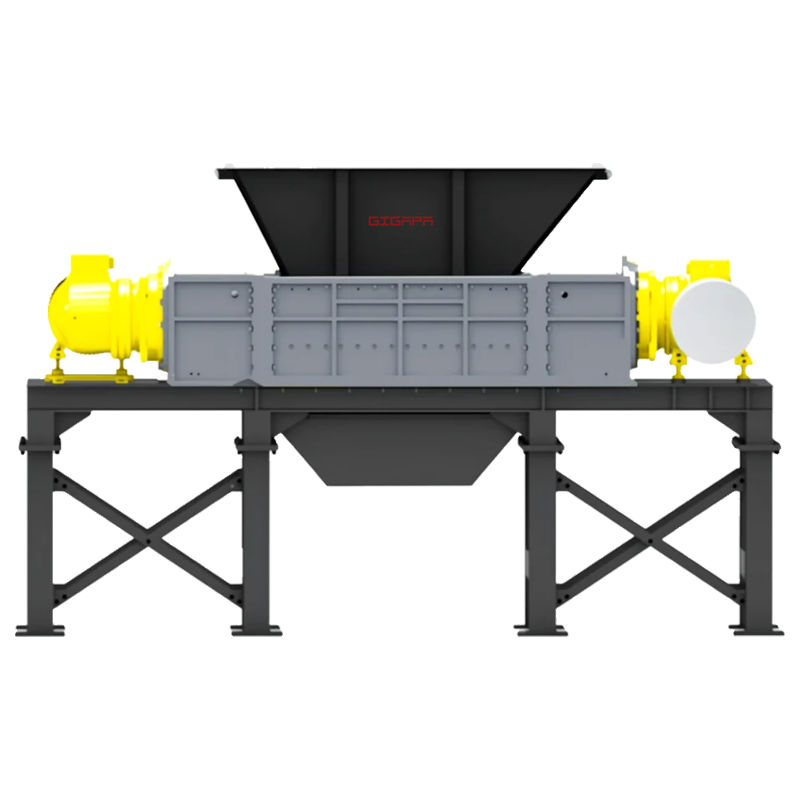

Equipment Introduction:

The motor drives a medium-ratio gear reducer through V-belts, which then rotates the cutter shaft. The rotating blades on the shaft tear materials and create shearing action against stationary blades. The single-shaft shredder material is carried into the chamber – when particle size becomes smaller than the screen mesh, it falls through; otherwise, it gets recirculated for further shredding. The unique shredding mechanism enables the single-shaft shredder to process large lump materials and even compressed material bales. Operating at medium-low speed provides high torque and efficiency. The equipped screen mesh effectively controls output particle size. These advantages give it wide applicability, making it a frequent choice in various solid waste recycling projects.

Application Range:

| Plastic | plastic sheets, pipes, films, pallets, household appliance shells, beverage bottles, woven bags, and other plastic products. |

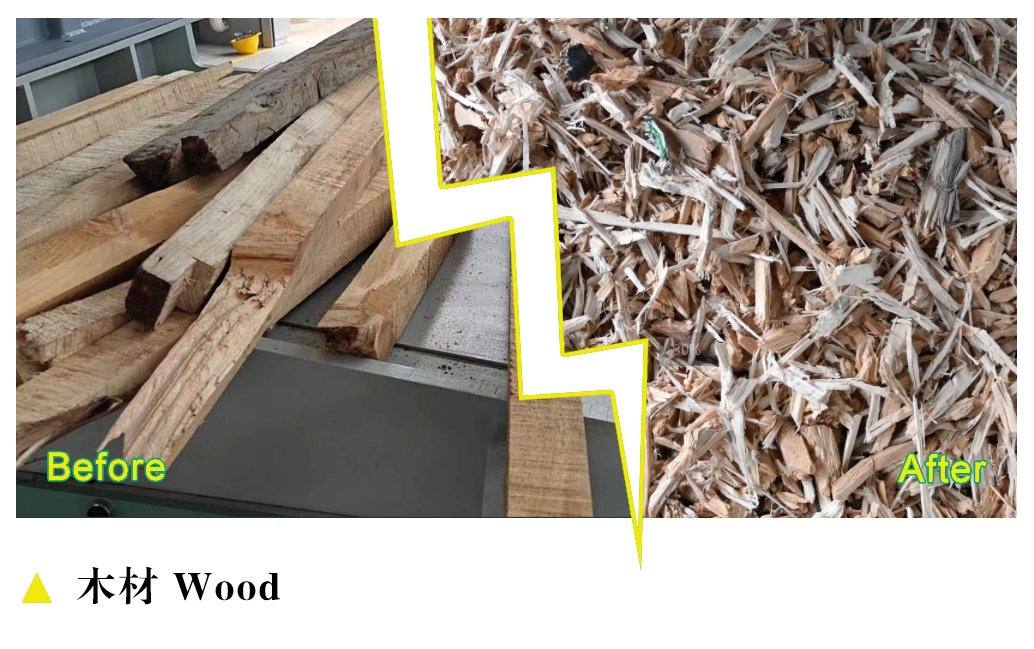

| Wood | waste wood, wood scraps, wooden molds, wooden pallets, wooden doors, wooden tables and chairs, etc. |

| Paper | office paper, wrapping paper, cardboard, books, paper trays, etc. |

| Fabric and leather | leather scraps, synthetic fiber cloth, cotton cloth, textile materials, carpets, clothes, curtains, etc. |

| Metals | aluminum scraps, aluminum cans, aluminum profiles, etc. |

| Others | colored steel tiles, sponges, foam, latex, fakes, substandard goods, expired items, etc. |

Model Parameters:

| Model | GSS-F206 | GSS-F308 | GSS-F310 | GSS-F312 | GSS-F314 | GSS-F415 |

|---|---|---|---|---|---|---|

| Crushing chamber size (mm) | 500×570 | 815×770 | 815×970 | 815×1170 | 815×1370 | 1100×1470 |

| Swing diameter (mm) | φ224 | φ392 | φ392 | φ392 | φ392 | φ480 |

| Mesh aperture (mm) | φ40 | φ40 | φ40 | φ40 | φ40 | φ40 |

| Motor power (kW) | 18.5 | 37 | 45 | 55 | 75 | 110 |

| Dimensions (L×W×H) (mm) | 1880×1300×1730 | 2810×1770×2120 | 2810×1970×2120 | 2810×2490×2120 | 2810×2710×2120 | 3700×2840×2530 |

| Overall weight (kg) | Approx 1600 | Approx 4000 | Approx 4300 | Approx 5300 | Approx 5900 | Approx 11400 |

The above models are standard universal models. If you require other models, please contact our staff, and we can also provide customized services according to your needs.

Technical Highlights:

1. High Cost-effectiveness

High hardness, wear-resistant, can be reused multiple times by replacing the angle

2. Good Stability

Unique liquid and debris channels, protecting the hydraulic system from interference.

3. High Safety

Fixed knives can not only be adjusted but also locked, effectively preventing collision with knives.

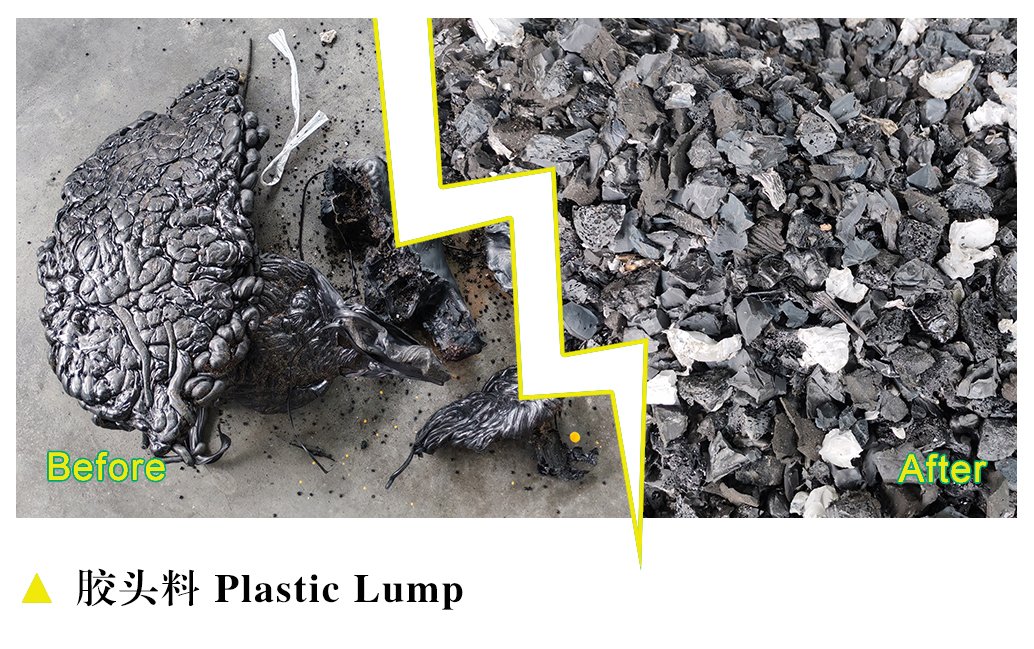

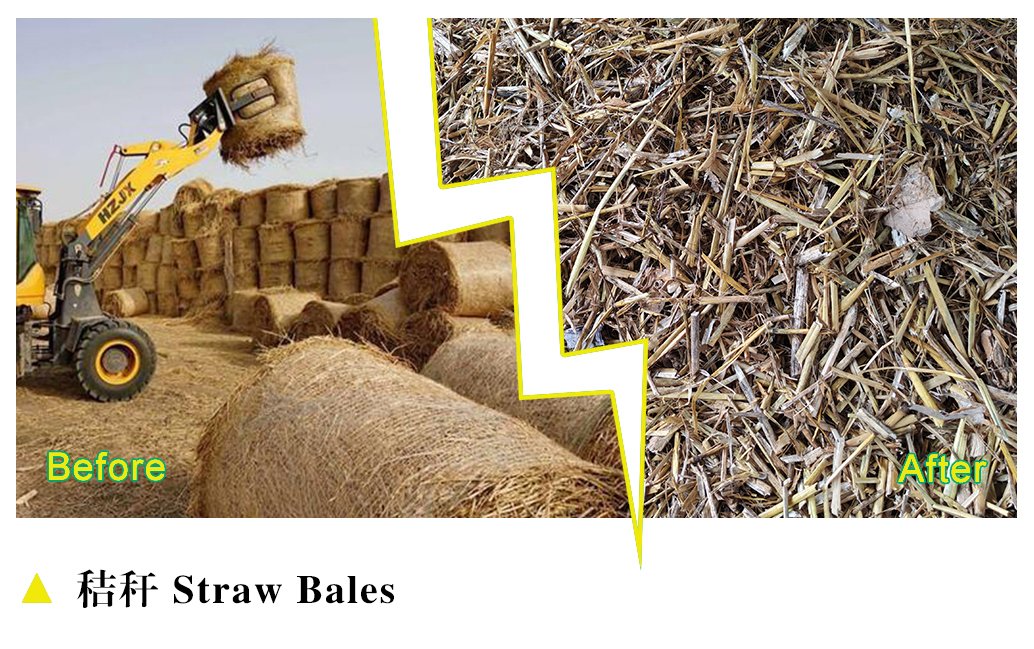

Effect Comparison:

Working Principle

Single-shaft shredder is a kind of mechanical equipment widely used in the crushing and processing of waste plastics, wood, rubber, metal and other materials. Its core working principle can be systematically described as follows:

1. Core structure composition

1.1 Power system

Adopt high-torque motor (30-200kW) or hydraulic drive, transmit power through reducer/gearbox to ensure low-speed high-torque output (speed is usually 15-60rpm).

1.2 Shredding unit

- Spindle: forged with high-strength alloy steel, surface hardened (hardness above HRC55), equipped with removable blade seat.

- Moving knife: 6-40 pieces, made of D2/H13 tool steel, fixed by hydraulic nut, and the blade edge is arranged in a spiral to reduce the impact load.

- Fixed knife: 2-4 pieces, forming a shear angle with the moving knife (usually 15°-25°), the material matches the moving knife.

1.3 Screen system

Replaceable screen plate (aperture 10-100mm optional), control the particle size of the discharge, manganese steel material to extend the service life.

1.4 Hydraulic system

Equipped with a push cylinder (pressure 10-20MPa) and a knife box opening and closing cylinder to achieve automatic feeding and maintenance and fast opening of the cabin.

2. Workflow

2.1 Feeding stage

The material is put into the hopper through the conveyor belt/manually, and the hydraulic push plate (or gravity feeding) presses the material to the rotating knife shaft.

2.2 Shredding stage

- Shearing action: The moving knife and the fixed knife form an interlaced shearing to cut the material into strips.

- Tearing action: The axial tension generated by the spiral layout of the blade breaks the material fiber.

- Squeezing action: The material is repeatedly rubbed and crushed between the blade and the screen.

2.3 Discharging control

After crushing, the material is filtered through the screen, and the qualified particles are discharged, and the unqualified material blocks continue to be circulated and crushed.

3. Technical characteristics

3.1 Intelligent control

- The PLC system monitors parameters such as current and temperature in real time, and automatically reverses/stops when overloaded.

- Optional metal detection interlocking device can be used to prevent hard foreign objects from damaging the tool.

3.2 Adaptable design

- Optional knives can be selected for different materials (such as double-edged knives for metals and hook-shaped knives for fibers).

- Adjustable knife gap (0.1-5mm) to adapt to changes in material thickness.

3.3 Safety mechanism

- Electrical and hydraulic double locking, physical locking of the knife shaft during maintenance.

- Noise control <85dB (with soundproof cover design).

-200x45.png)