Product Description:

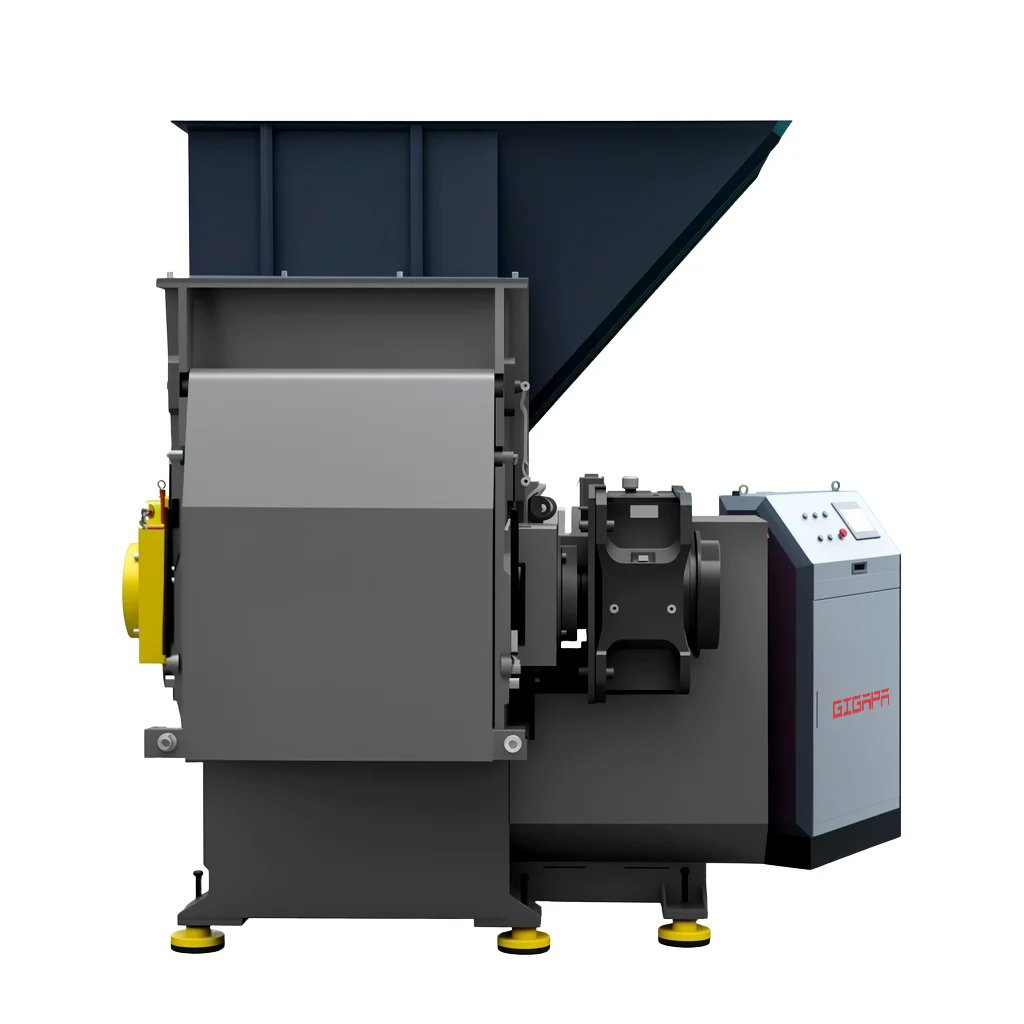

The Single Shaft Shredder (Flat Pushing) is an advanced industrial waste shredding solution designed for high-efficiency material reduction in a wide range of industries. Featuring a flat-pushing mechanism that ensures consistent material feeding, this shredder is engineered to handle bulky, dense, or irregular waste materials with superior precision and reliability.

In modern manufacturing, recycling, and waste management sectors, effective size reduction is essential for improving downstream processing, reducing disposal costs, and achieving sustainable operations. Whether you’re dealing with plastic scrap, wood blocks, textile remnants, rubber offcuts, or light metals, the Single Shaft Shredder (Flat Pushing) offers a compact yet powerful answer to your material handling needs.

Key Advantages of the Single Shaft Shredder (Flat Pushing):

1. Optimized Feeding with Flat Pushing System

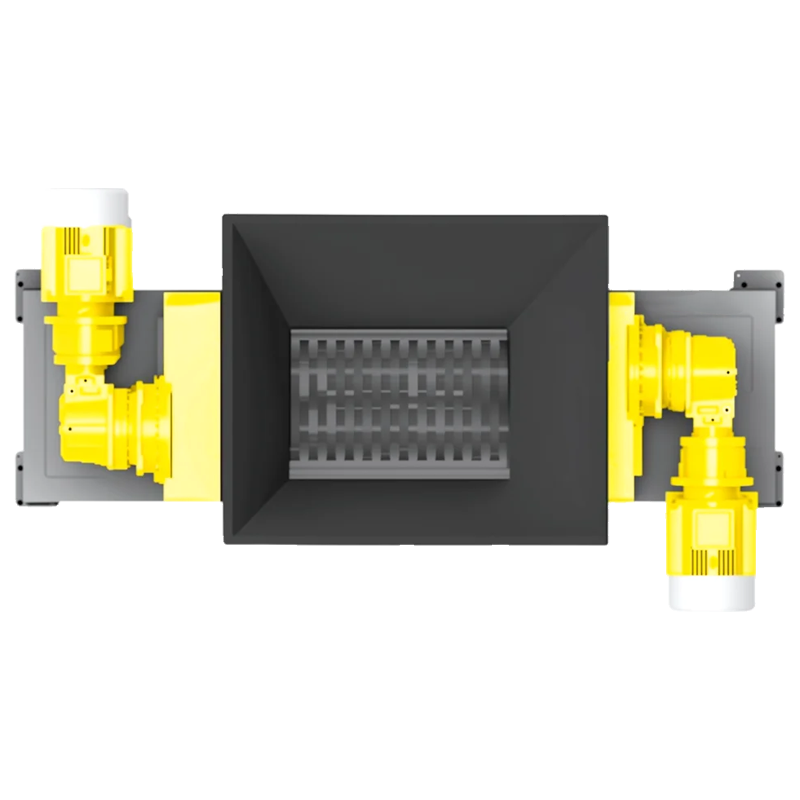

The standout feature of this model is its flat pushing system. Unlike gravity-fed or rotary-feeding systems, flat pushing provides uniform pressure across the feed chamber. This allows for smoother and more controlled material intake, especially with uneven, bulky, or hard-to-grip materials. The result is a continuous shredding flow with minimal material jams and interruptions.

2. Versatile Waste Handling

The Single Shaft Shredder (Flat Pushing) is a multi-purpose machine capable of processing a diverse range of materials. Whether you’re working with rigid plastics, soft film, thick rubber, packaging waste, textiles, or even electronic waste, this shredder adapts to your needs. It is especially effective for pre-processing waste before granulation, incineration, or recycling.

3. Superior Material Size Reduction

This shredder is equipped to transform large, unwieldy items into uniform fragments, enhancing the efficiency of further processing stages such as sorting, compacting, or extrusion. The consistent particle size achieved with this machine contributes to higher-value recycled output and improved logistics handling.

4. Industrial-Grade Durability and Reliability

The single-shaft shredder is built for demanding industrial environments. Its robust structure and wear-resistant components ensure long-term durability even under continuous use. With a heavy-duty rotor and high-performance cutters, this shredder can withstand abrasive materials and harsh operating conditions.

5. Automation-Ready and Low Maintenance

With intelligent design features like automatic pushing control, reverse rotation for jam prevention, and easy access maintenance points, the machine delivers high operational uptime and lower manual labor requirements. The flat-pushing plate is controlled with precision to maximize throughput while protecting internal components.

6. Noise and Dust Control for Safer Work Environments

Industrial shredding can be noisy and dusty, creating an uncomfortable or hazardous workplace. The Single Shaft Shredder (Flat Pushing) addresses this with insulated enclosures, controlled feed speeds, and dust-limiting design features. This makes it more suitable for indoor factory use or near-employee work zones.

7. Space-Efficient and Easy to Integrate

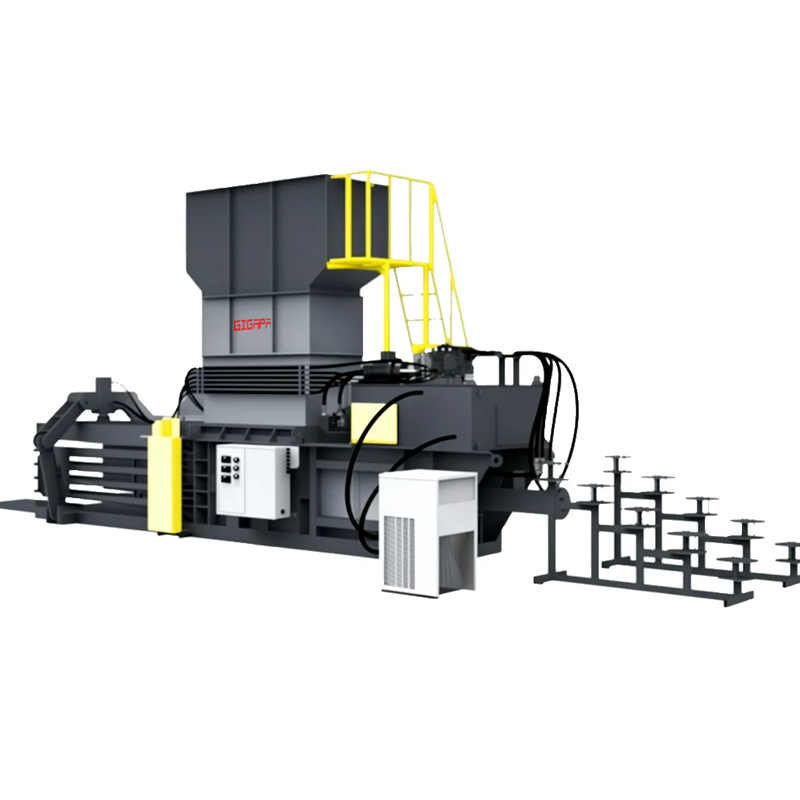

Thanks to its compact footprint and vertical-pushing design, the machine saves floor space and fits seamlessly into existing production lines or recycling systems. It can be integrated with conveyors, balers, granulators, or storage silos depending on the requirements of your operation.

8. Energy Efficiency and Environmental Benefits

Efficient waste shredding not only reduces disposal costs but also contributes to more sustainable industrial practices. By reducing waste volume at the source, this shredder helps lower fuel use in transport and improves recycling rates. Its energy-efficient operation means lower power consumption over time, aligning with green manufacturing goals.

Common Applications:

- Plastic industry: Pre-shredding of injection molding runners, plastic sheets, bottles, film, and containers.

- Wood processing: Shredding wood offcuts, pallets, fiberboard, and timber packaging materials.

- Textile and garment: Handling scrap fabric, old clothes, nonwoven waste, and textile rolls.

- Rubber and foam: Reducing tire fragments, rubber seals, insulation foam, and cushioning material.

- Electronic waste (e-waste): Processing keyboards, cables, casings, and small electronics.

- General industrial waste: Mixed manufacturing scrap, packaging waste, and defective products.

Why Choose the Flat Pushing Model?

The flat pushing mechanism gives this shredder an edge in terms of processing consistency and material adaptability. While traditional shredders may struggle with oversized or awkwardly shaped waste, the flat pushing action ensures materials are pressed directly and evenly toward the cutting rotor. This not only improves throughput but also enhances the quality and predictability of shredded output.

Moreover, the design minimizes idle time between shredding cycles, as the pusher maintains constant contact with the material bed. This results in higher processing efficiency and reduced operational costs. Maintenance is simplified with easily replaceable cutting tools and intuitive access panels for cleaning and adjustments.

Conclusion:

The Single Shaft Shredder (Flat Pushing) is a professional-grade waste reduction machine that delivers consistent performance, excellent versatility, and exceptional reliability. Suitable for a wide range of industries—from plastics and packaging to textiles and e-waste—it is a smart investment for businesses seeking efficient, cost-effective, and environmentally responsible waste management.

Its combination of a flat-pushing feed system, rugged construction, and automation-ready controls makes it ideal for companies looking to enhance their shredding capacity and integrate size reduction into broader recycling or production processes.

Whether you’re upgrading your waste handling system or building a new processing line, the Single Shaft Shredder (Flat Pushing) offers the strength, flexibility, and precision your operation demands.

-200x45.png)