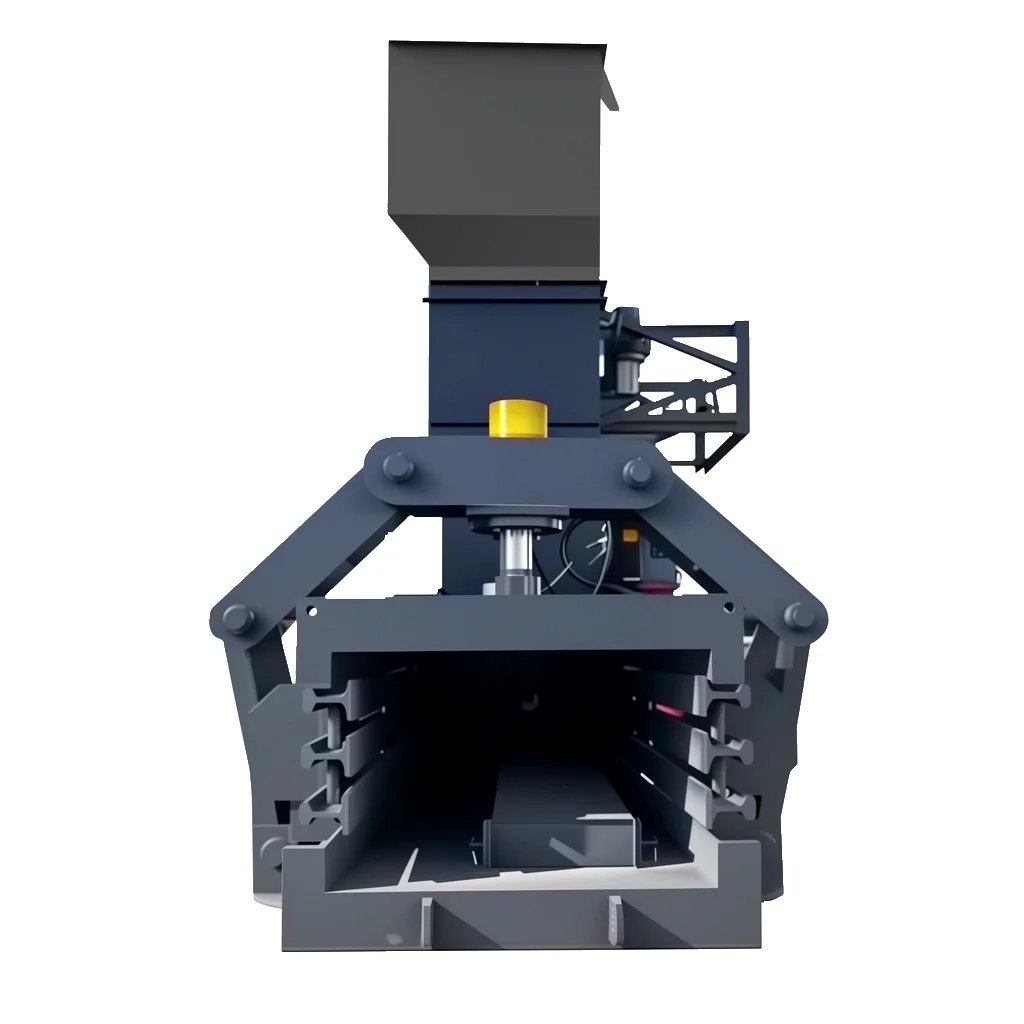

In today’s increasingly eco-conscious and efficiency-driven industrial environment, waste management has become a critical priority across many sectors. Whether in manufacturing, retail, distribution, or logistics, businesses are constantly looking for solutions that are cost-effective, space-saving, and environmentally responsible. The standard vertical hydraulic baler with manual door opening offers a reliable, user-friendly, and budget-friendly solution for compacting a wide range of recyclable waste materials.

This vertical baler is specifically designed to meet the needs of businesses that produce moderate volumes of waste materials like cardboard, paper, textiles, plastic film, and soft packaging. It compresses these materials into tightly packed bales that are easier to store, transport, or recycle, allowing companies to reduce disposal costs, maintain tidier workspaces, and demonstrate environmental responsibility.

Space-Saving Vertical Design

The vertical configuration of this baler is ideal for businesses with limited floor space. Its upright structure means it can be installed in smaller areas such as warehouses, back-of-store spaces, and narrow loading docks without interfering with day-to-day operations. The compact footprint doesn’t sacrifice performance and still delivers high compaction force, making it a preferred choice for small to medium enterprises.

Manual Door Opening for Safe and Simple Operation

The manual door opening feature offers controlled and safe access to the loading chamber. This design allows operators to manually open and close the front door when loading materials or removing finished bales. Unlike automated doors that require more complex mechanisms and maintenance, the manual system reduces mechanical complexity and enhances machine reliability.

Additionally, manual door operation increases user control, which can be particularly beneficial when processing inconsistent or irregular materials such as textile offcuts or crumpled cardboard. Operators can monitor the chamber closely, position materials properly, and ensure maximum load efficiency before compression.

Ideal for a Wide Range of Materials

The standard vertical hydraulic baler is engineered for multi-material compaction. It is widely used in handling:

- Corrugated cardboard boxes (OCC)

- Office paper and shredded documents

- Plastic films, shrink wraps, and packaging waste

- Textiles, rags, and garment scraps

- Aluminum cans and PET bottles (dry)

- General dry solid waste

This versatility makes the machine an excellent all-around baler for companies with diverse waste streams. It also promotes material separation at the source, helping businesses comply with local recycling regulations and improve recycling efficiency.

Cost-Effective Waste Reduction

By compressing large volumes of loose waste into smaller, denser bales, the vertical baler offers direct financial benefits, including:

- Lower waste collection frequency

- Reduced transportation and landfill fees

- Minimized storage requirements

- Enhanced facility cleanliness and safety

These savings quickly add up, especially for businesses with recurring packaging waste. Additionally, well-formed bales can be sold or transported to recyclers, turning waste into potential revenue.

User-Friendly and Low Maintenance

The baler is designed with simplicity in mind, making it easy for operators to use with minimal training. Basic functions are intuitive, allowing for quick onboarding and consistent operation even in high-turnover environments. The manually operated door mechanism also contributes to fewer breakdowns and lower maintenance needs over time, reducing downtime and service costs.

Key benefits for users include:

- Easy-to-understand control interface

- Manual feed system at waist height

- Simple bale removal and tie-off process

- Durable components designed for long life

These features make it especially suitable for small businesses or operations without dedicated waste management staff.

Applications Across Multiple Industries

The flexibility, reliability, and affordability of this baler make it suitable for a broad range of industries and sectors, including:

- Retail and supermarkets – For daily packaging waste such as cardboard boxes and shrink wrap

- Warehousing and logistics – For plastic films, paper, and discarded packaging

- Garment and textile factories – For fabric scraps and defective clothing

- Food and beverage outlets – For dry packaging materials and cans

- Hospitality sector – Hotels and resorts managing high volumes of guest-related packaging waste

- Commercial offices – For paper waste and internal recycling programs

Its manual door design allows for easy integration into existing workflows without requiring complex upgrades or automation.

A Smart Investment for Sustainable Growth

The Standard Vertical Hydraulic Baler – (Manual Door Opening) is more than just a machine—it’s a strategic investment in efficiency, cleanliness, and sustainability. With growing waste disposal costs and increasing consumer demand for eco-conscious operations, businesses must implement waste reduction strategies that deliver real value.

This baler offers exactly that: reliable performance, minimal maintenance, simple operation, and immediate cost savings. Whether you’re just starting to organize your waste or looking to upgrade from loose-bin disposal, this baler provides a smart, scalable solution.

Conclusion

If your business generates recyclable waste and you’re looking for an affordable, efficient, and environmentally friendly way to manage it, the Standard Vertical Hydraulic Baler with Manual Door Opening is the ideal choice. Designed to balance simplicity with functionality, this baler is the perfect companion for any company aiming to streamline operations, cut costs, and support a greener future.

-200x45.png)