A steel swarf compactor is an essential piece of equipment in modern metalworking and recycling plants. It is designed to compress loose steel chips, turnings, and other metallic swarf into dense, dry, and easy-to-handle briquettes. This not only reduces the storage space required for metal waste but also makes the material more valuable for recycling or smelting. For manufacturers that process steel, stainless steel, cast iron, or aluminum, investing in a steel swarf compactor significantly improves both environmental compliance and operational efficiency.

Working Principle of the Steel Swarf Compactor

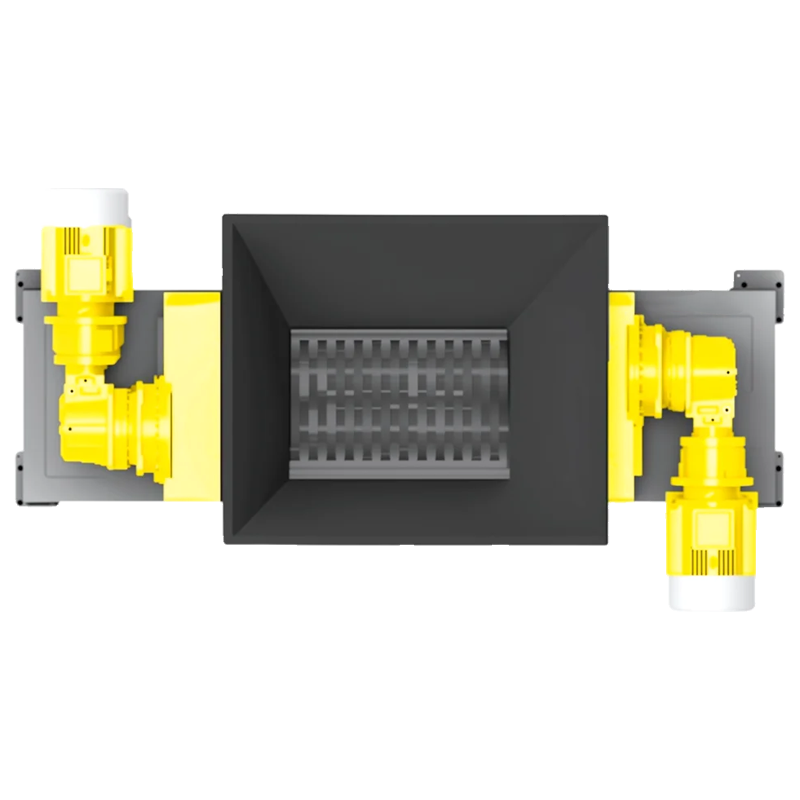

The steel swarf compactor operates through a combination of hydraulic pressure and mechanical compression. After the swarf is collected from machining or grinding operations, it is fed into the hopper of the compactor. Inside the compression chamber, a powerful hydraulic cylinder exerts high pressure—often exceeding 2000 psi—on the loose steel chips. This pressure squeezes out cutting fluids, coolants, and other residual oils while forming compact, solid briquettes.

The resulting briquettes are typically cylindrical or block-shaped and have a much higher density compared to loose swarf. They can be easily stacked, stored, or transported to smelting facilities without contamination or fluid leakage. The extracted coolant can also be filtered and reused, contributing to a cleaner and more sustainable production process.

Advantages of Using a Steel Swarf Compactor

-

Space and Cost Savings

Loose steel chips occupy a large volume. By compacting them into solid briquettes, storage requirements can be reduced by up to 80%. This leads to lower logistics and handling costs. -

Recycling Efficiency

Compact briquettes have a higher bulk density, which improves furnace charging efficiency during remelting. As a result, energy consumption is reduced and the overall recycling rate increases. -

Oil and Coolant Recovery

The compaction process separates and recovers residual cutting fluids from the swarf. These fluids can be reused, minimizing waste and improving sustainability. -

Clean and Safe Working Environment

Briquetting eliminates dripping oils and scattered chips from the workshop floor, creating a cleaner, safer, and more organized workspace. -

Environmental Compliance

The steel swarf compactor supports compliance with modern environmental standards by reducing waste volume, preventing fluid leakage, and promoting recycling.

Technical Features

- High-Pressure Hydraulic System – Ensures maximum compaction density and stable briquette formation.

- Automatic Feeding and Discharging – Reduces labor requirements and increases production efficiency.

- Programmable Control (PLC) – Enables fully or semi-automatic operation with simple settings.

- Durable Compression Chamber – Made from wear-resistant steel to ensure long-term reliability.

- Oil Recovery System – Collects and separates coolants or lubricants for recycling.

- Optional Cooling and Filtration System – Keeps hydraulic oil clean and extends machine lifespan.

Applications

The steel swarf compactor is widely used in industries such as:

- Metalworking and machining centers

- Automotive and aerospace component manufacturing

- Steel and stainless-steel fabrication plants

- Foundries and smelting operations

- Recycling and waste management facilities

Whether the material is steel, cast iron, or non-ferrous metals, the compactor effectively converts waste into valuable resources, supporting a circular economy.

Why Choose Our Steel Swarf Compactor

Our company specializes in designing and manufacturing industrial briquetting and recycling equipment with over ten years of engineering experience. Each steel swarf compactor is designed for heavy-duty performance, easy maintenance, and consistent operation. Custom solutions are available according to customer requirements, including feeding systems, automatic conveyors, or fully integrated recycling lines.

We provide comprehensive technical support, from equipment selection to installation and after-sales service. Our goal is to help manufacturers reduce waste, improve efficiency, and achieve sustainable production.

Conclusion

A steel swarf compactor is not just a waste management machine—it is a smart investment that brings measurable benefits in cost reduction, environmental protection, and productivity improvement. By turning loose steel swarf into dense briquettes, you can simplify storage, recover valuable fluids, and contribute to a cleaner industrial process.

If you are looking for a reliable steel swarf compactor manufacturer or supplier, contact us today to discuss your project requirements. Our professional team will recommend the most suitable model and provide a complete metal recycling solution tailored to your needs.

-200x45.png)