Introduction

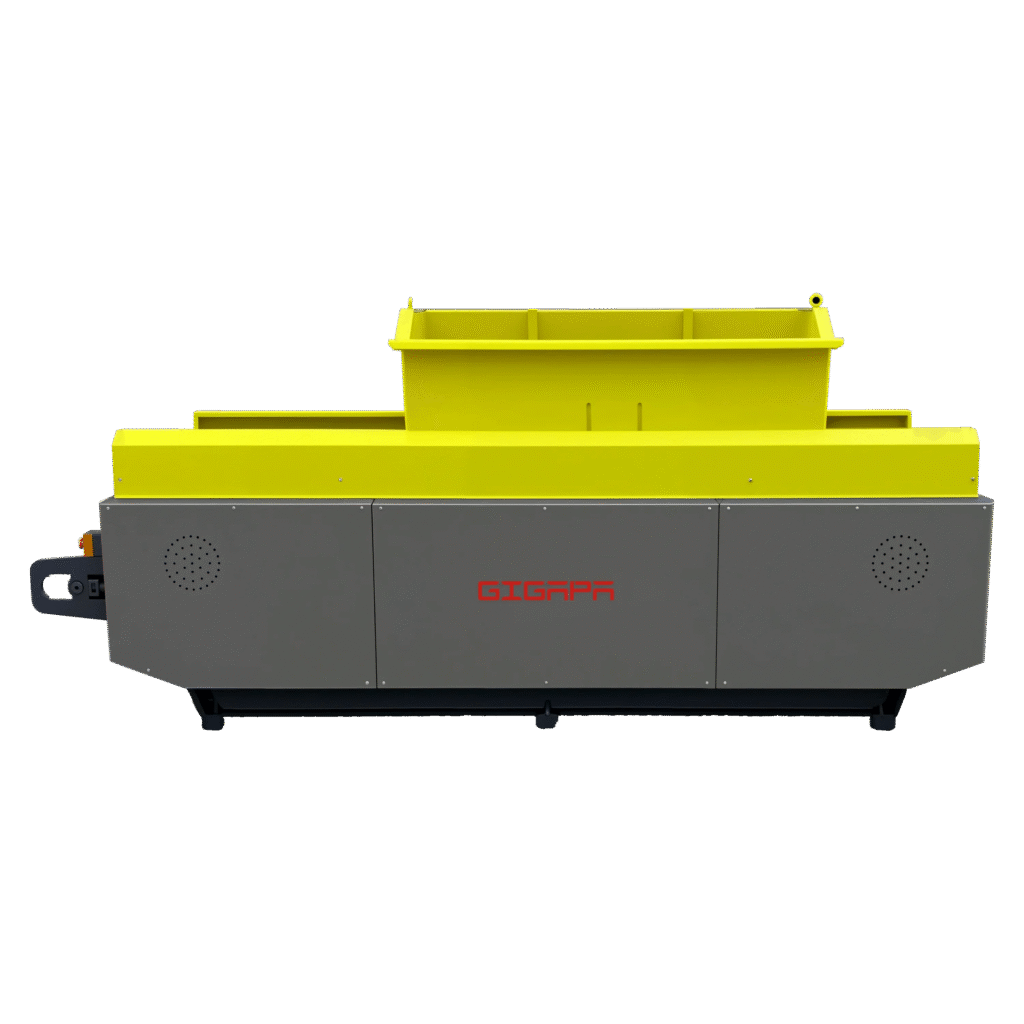

The wood chip shaving machine is a specialized piece of equipment designed for efficiently producing wood shavings from wood chips. This machine is widely used in various industries such as wood processing, animal bedding production, and even in the manufacturing of composite wood products. It is engineered to deliver high efficiency, durability, and precision in shaving wood into fine, uniform shavings that meet industry standards.

Whether you are in the business of creating animal bedding materials or wood-based products, the wood chip shaving machine is an essential tool to enhance your productivity and reduce waste. This versatile machine can handle different types of wood chips and produce shavings in various sizes, making it a valuable asset for businesses looking to optimize their wood processing capabilities.

Features of the Wood Chip Shaving Machine

-

High Efficiency and Output

The wood shaving making machine is designed for high-speed production, ensuring a steady output of wood shavings. The machine’s efficient operation minimizes downtime, allowing for consistent production in large volumes. It is ideal for businesses looking to meet high demand while maintaining operational efficiency. -

Customizable Shaving Size

One of the most significant advantages of the wood chip shaving machine is its adjustable shaving size feature. Depending on the application, operators can easily adjust the thickness and texture of the shavings. This flexibility makes it suitable for multiple industries, from creating fine shavings for animal bedding to coarser shavings used in wood-based products. -

Robust and Durable Construction

Built with high-quality materials, the wood shaving making machine is designed to handle the demands of heavy-duty wood processing. The machine’s durable construction ensures a long service life, even under continuous operation. It can withstand wear and tear, providing a reliable solution for businesses that rely on consistent performance. -

Low Maintenance Requirements

The machine’s design also incorporates easy-to-maintain components. With minimal moving parts, the wood chip shaving machine is simple to service, reducing the need for costly repairs or prolonged downtime. Regular maintenance ensures the machine’s optimal performance and longevity, making it a cost-effective investment. -

Eco-Friendly Operation

The machine operates in an environmentally responsible manner by efficiently utilizing wood waste. Instead of discarding wood chips as waste, the wood shaving making machine transforms them into useful shavings, contributing to a reduction in environmental impact. This makes it an excellent choice for companies looking to adopt sustainable practices.

Applications of the Wood Chip Shaving Machine

The wood shaving making machine has a wide range of applications, making it an essential piece of equipment for various industries. Some of the most common uses include:

-

Animal Bedding

One of the most common applications of the wood chip shaving machine is in the production of animal bedding. The fine, soft shavings produced by the machine are ideal for providing a comfortable and hygienic environment for animals. These shavings are absorbent, helping to manage moisture and reduce odors in animal enclosures. -

Wood-based Product Manufacturing

The shavings produced by the wood shaving machine are often used in the manufacturing of wood-based products such as particleboard, MDF (medium-density fiberboard), and plywood. These shavings serve as raw materials that are mixed with adhesives and compressed to form sturdy composite wood products. -

Wood Pellets Production

The shavings generated by this machine can also be used as raw material for making wood pellets. These pellets are commonly used in heating systems, as well as in industrial applications. The fine and uniform shavings produced by the machine ensure that the resulting pellets have a consistent size and burn efficiency. -

Packaging Materials

Shavings produced by the Wood Chip Shaving Machine can be utilized for creating eco-friendly packaging materials. These shavings can be used as cushioning for fragile products, replacing traditional packaging materials like foam or plastic. -

Landscaping and Mulch

Wood shavings can be used in landscaping projects and as mulch in gardens. The wood chip shaving machine can produce shavings that are uniform in size, making them perfect for use in garden beds, flower pots, and lawns.

How the Wood Shaving Machine Works

The wood chip shaving machine operates through a series of mechanical processes that transform wood chips into finely shaved material. The machine consists of a feed hopper, rotating blades, and a discharge system. Here’s a brief overview of how it works:

-

Feeding Wood Chips

Wood chips are fed into the machine through the feed hopper, which guides them into the shaving chamber. -

Shaving Process

Inside the shaving chamber, the wood chips are sliced by high-speed rotating blades. The blades are designed to cut the wood into thin, uniform shavings. The size of the shavings can be adjusted by modifying the blade settings. -

Shavings Discharge

Once the wood chips are processed into shavings, the final product is discharged through an output chute. The shavings are then collected and processed further, depending on the intended application.

Benefits of the Wood Chip Shaving Machine

-

Cost-Effective

The wood shaving machine is an affordable solution for businesses looking to process wood waste into valuable products. Its efficiency and durability ensure a low cost of ownership, making it a wise investment for companies in wood processing, animal bedding, and other industries. -

Improved Waste Management

By converting wood chips into shavings, this machine helps businesses manage wood waste effectively. Rather than sending wood chips to landfills, companies can repurpose them into useful products, contributing to better resource utilization. -

Enhanced Productivity

With its high-output capabilities, the wood chip shaving machine boosts productivity by reducing processing times and minimizing downtime. This allows businesses to meet high-demand production requirements without compromising quality. -

Versatility

The machine’s ability to adjust shaving sizes makes it versatile enough to cater to various industries. Whether you’re producing fine shavings for animal bedding or larger shavings for composite wood products, the wood shaving machine provides the flexibility you need.

Conclusion

The wood chip shaving machine is a highly efficient and versatile solution for processing wood chips into fine, uniform shavings. Its robust design, customizable features, and eco-friendly operation make it a valuable asset for industries such as animal bedding production, wood-based product manufacturing, and landscaping. With its ability to streamline operations and reduce waste, the wood shaving machine offers a cost-effective and sustainable solution for businesses looking to enhance productivity and resource utilization.

By investing in a wood chip shaving machine, businesses can not only improve their bottom line but also contribute to a more sustainable and environmentally friendly industry.

-200x45.png)