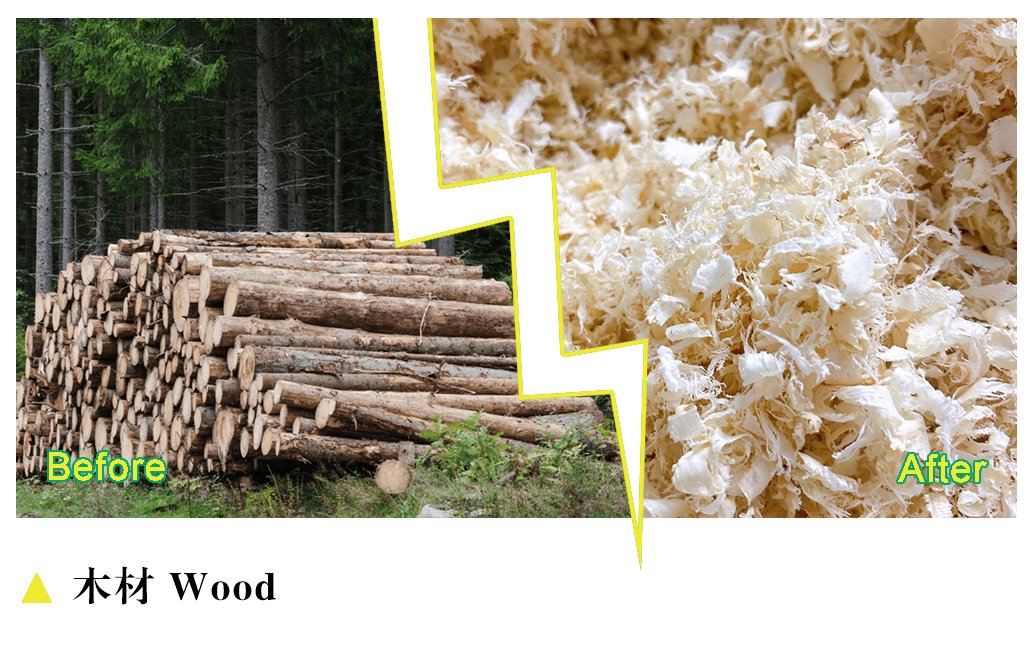

Equipment Introduction:

The high-linear-speed blades of the wood shavings machine rapidly plane wood to produce thin wood flakes. As the wood in the flaker box moves reciprocally relative to the cutter shaft through chain-driven mechanism, the blades continuously plane all surfaces of the material, generating consistent wood flakes that are discharged via the under-mounted conveyor.

The main motor of the wood shaving machine directly drives the knife shaft to rotate through the V-belt, and the high-speed blade quickly shaves the wood to produce thin wood shavings. The planing box motor reducer drives the planing box to reciprocate through the sprocket chain, and the wood in the planing box also reciprocates with the planing box relative to the knife shaft. In this process, the blade continuously shaves various positions of the wood, and wood shavings are continuously produced. The produced shavings are then conveyed out through the conveyor belt below.

Application Range:

| Animal Breeding | Producing bedding materials for pets such as hamsters and laboratory animals like mice,

producing absorbent and insulating materials for farms such as for chickens, horses, and rabbits. |

| Packaging Materials | Producing wood shavings used as fillers for protecting fragile items during packaging. |

| Paper Industry | Producing fine wood shavings used as pulp material in the papermaking process. |

| Flower Breeding | Producing fine wood shavings used as organic fertilizer in horticulture. |

| Bioenergy | Producing fine wood shavings used as biomass fuel. |

| Furniture Manufacturing | Producing wood shavings used as raw material for making chipboards, fiberboards, and other types of boards. |

Model parameters:

| Model | GFW-C106 | GFW-C109 | GFW-C306 |

| Planer box dimensions(mm) | 1430×590 | 1430×890 | 2130×590 |

| Swing diameter(mm) | φ160 | φ160 | φ300 |

| Roller length(mm) | 600 | 900 | 600 |

| Motor power(kW) | 7.5×4 | 11×4 | 11×4 |

| Dimensions(L×W×H)(mm) | 3780×1600×1500 | 3780×2000×1500 | 4880×1850×2080 |

| Overall weight(kg) | Approx 2200 | Approx 2500 | Approx 5000 |

The above models are standard universal models. If you require other models, please contact our staff, and we can also provide customized services according to your needs.

Technical Highlights:

1. Strong adaptability

Can adjust the thickness of the wood chips and change the size of the chips according to needs.

2. High economy

Blades are highly hard and wear-resistant, and can be reused multiple times by grinding or changing angles.

3. Ease of operation

High degree of automation, simple and easy to operate.

FAQ

1. What is the quality of the wood shavings produced?

The machine produces uniform, high-quality shavings that are consistent in size and shape.

2. Is the wood shavings machine easy to operate?

Yes, the wood shavings machine is designed to be user-friendly with simple controls and minimal maintenance requirements. Operators can quickly learn to run the machine, and it can be integrated into existing production lines with ease.

3. Can the wood shavings machine process different types of wood?

Yes, the machine is capable of processing various wood types, including hardwood, softwood, and even treated or recycled wood. However, the performance may vary slightly based on the wood’s density and condition.

4. What is the size of the wood shavings produced?

The machine produces wood shavings of a uniform size, typically ranging from fine particles to larger shavings, depending on the machine’s settings. You can adjust the size of the shavings according to your needs.

5. Can I customize the wood shavings machine?

Yes, we offer customization options to suit specific requirements, such as adjusting the size of the wood shavings, integrating a dust collection system, or modifying the production capacity to match your operational needs.

The wood shavings machine (also known as wood chipper or wood flaker) is designed for wood processing, biomass energy and renewable resources industries, and has become an industry benchmark with its excellent cutting efficiency and stable performance.

Efficient cutting, flexible customization

- Wide range of processing capacity: can process logs, branches and wood scraps with a diameter of 10-50cm to meet the needs of diversified raw materials.

- Adjustable shavings specifications: supports customized shavings size (10-50mm) and thickness (0.1-0.8mm) to meet different application scenarios, such as biomass fuel, bedding production, etc.

High production capacity, stable operation

- Powerful processing capacity: The production capacity reaches 800-3000kg/h, suitable for small and medium-sized processing plants to large biomass energy projects.

- Intelligent power system: adopts high-efficiency motor/hydraulic drive (optional), with intelligent overload protection to ensure continuous and stable operation.

Industrial-grade durable design

- Core wear-resistant parts: high chrome alloy blade (HRC60+) and reinforced bearings to extend service life and reduce maintenance frequency.

- Low failure rate transmission: optimized chain drive/gearbox design, smoother operation, maintenance costs reduced by more than 30%.

Working principle

Feeding system

- Use heavy-duty chain conveyor or hydraulic feeding device to ensure continuous and stable supply of wood

- Equipped with metal detector to automatically remove mixed metal impurities

- The size of the feed port can be customized (standard 800×600mm)

Cutting and crushing unit

- The core component uses a high-chromium alloy cutter disc (hardness HRC58-62)

- The cutter disc speed is adjustable from 450-650rpm and equipped with a hydraulic tensioning system

- Multi-layer staggered blade design to handle wood with different moisture contents (15%-45%)

Grading and screening system

- Dual vibration screen configuration (aperture 10-50mm optional)

- Unqualified coarse materials are automatically returned for reprocessing

- Discharge uniformity reaches more than 90%

Power transmission system

- High torque gearbox (speed ratio 1:1.8)

- Optional 150-400kW motor or diesel unit

- Intelligent overload protection device response time <0.3 seconds

Intelligent control system

- PLC+touch screen operation interface

- Real-time monitoring of current/temperature/vibration parameters

- With production statistics and fault self-diagnosis functions

-200x45.png)