In today’s fast-evolving agricultural landscape, efficiency, space utilization, and cost-effectiveness are critical to a farm’s success. One significant challenge farmers face is how to handle large volumes of loose materials such as straw, hay, or crop residues. Traditionally, baling methods such as round and square balers have been used. However, with the growing need for compact storage, cleaner handling, and better logistics, the straw bagging baler has emerged as a powerful alternative.

In this article, we’ll provide a comprehensive comparison between the straw bagging baler and traditional baling methods, helping you determine the most suitable solution for your operation.

What is a Straw Bagging Baler?

A straw bagging baler is a type of agricultural or industrial machinery used to compress loose materials—like straw, hay, waste paper, plastics, cotton, and more—into tightly packed units that are then sealed inside bags such as woven sacks, burlap bags, or plastic film. This machine uses high-pressure compression to significantly reduce the volume of material, making it easier to transport, store, and reuse.

Compared to conventional balers that produce twine-bound or net-wrapped bales, straw bagging balers encapsulate the material in a protective layer, improving cleanliness and longevity. They are especially useful in environments where hygiene, moisture protection, and logistics are priorities.

Overview of Traditional Baling Methods

Traditional balers—including round and square balers—have been used for decades in the field. These machines collect and compress loose straw or hay into bales of fixed shapes and sizes, which are then tied with twine or wrapped in netting. Once baled, they are transported manually or by machine to a storage area, often covered to protect from the elements.

While traditional balers are reliable and widely adopted, they come with certain disadvantages such as exposure to moisture, labor intensiveness, and storage inefficiency.

Comparing Straw Bagging Baler and Traditional Baling

1. Material Handling and Cleanliness

- Traditional Baling: The bales are typically left uncovered or stored under tarps. This exposes them to dust, insects, and weather elements, reducing the overall quality.

- Straw Bagging Baler: Bagged bales are sealed immediately after compression, protecting them from moisture, dirt, and pests. This is especially beneficial for industries that require clean straw, such as mushroom farming or livestock bedding.

2. Storage Efficiency

- Traditional Bales: Large, uneven bales can be difficult to stack. They also require more space due to their bulky, unsealed form.

- Bagged Bales: Uniformly shaped and sealed bales can be tightly stacked, reducing storage footprint and maximizing warehouse or barn space.

3. Moisture and Weather Protection

- Traditional Baling: Requires covered or indoor storage. Exposure to rain can cause mold, rot, or fermentation.

- Straw Bagging Baler: The bagging process creates a moisture-resistant seal, protecting straw even in semi-open storage conditions.

4. Labor and Operational Efficiency

- Traditional Baling: Involves several manual steps—baling, loading, covering, and unloading. Labor demand is higher, particularly during peak harvest seasons.

- Straw Bagging Baler: As a fully automatic system, the straw bagging baler compresses, bags, and seals straw in one continuous cycle. This dramatically reduces labor costs, speeds up processing, and allows a single operator to manage the entire operation.

5. Cost Implications

- Traditional Balers: Lower initial cost, especially if purchasing older models. However, higher long-term costs due to labor, storage, and material loss.

- Straw Bagging Balers: Higher upfront investment, but more cost-effective over time due to efficiency gains and material protection.

Applications of Straw Bagging Baler

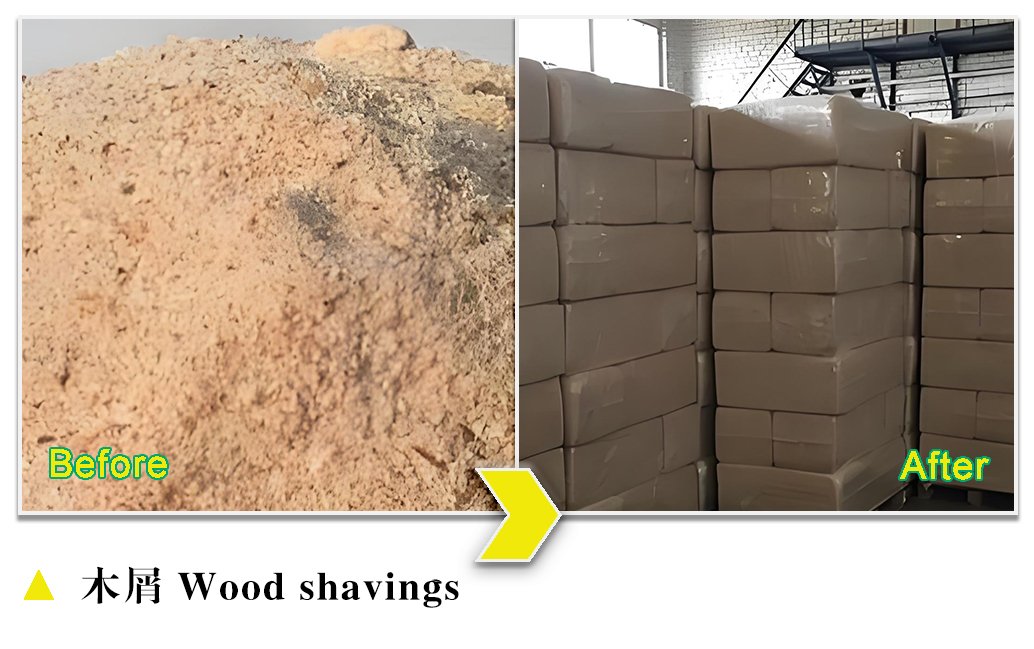

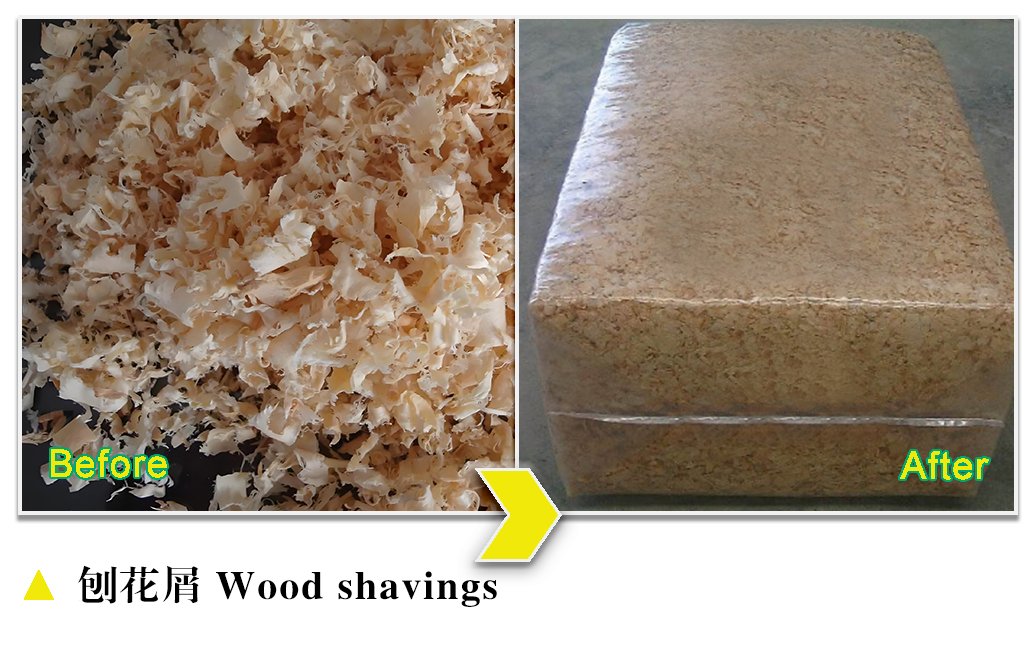

| Wood | Wood shavings, sawdust, etc. |

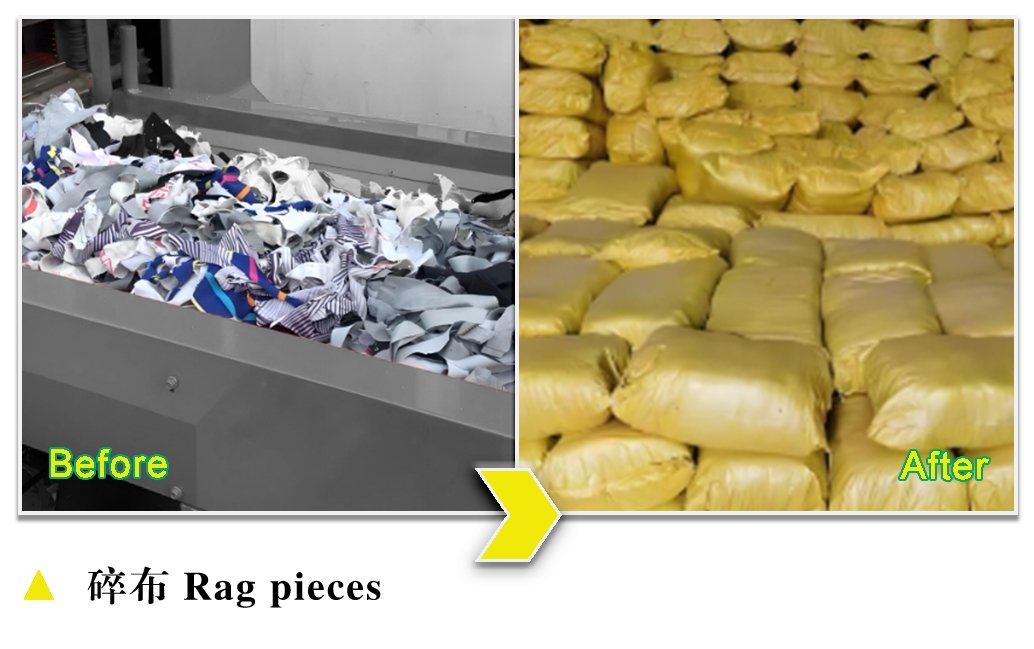

| Fabric and Leather | Clothing, rags, factory offcuts, textile scraps, leather scraps, etc. |

| Plants | Rice husks, alfalfa, silage feed, cottonseed hulls, etc. |

| Paper | Shredded currency, paper scraps, etc. |

| Soil | Peat soil, coir soil, etc. |

| Others | Rubber granules, sponge, foam, latex, etc. |

Working Principle of Straw Bagging Baler

The straw bagging baler primarily operates based on hydraulic transmission and mechanical compression technologies. The machine uses a feeding system to deliver straw into the compression chamber. Then, powerful hydraulic cylinders generate high pressure to compress the straw into dense and uniform bales. The size, shape, and density of the bales can be flexibly adjusted by configuring the machine’s operating parameters.

In terms of structure, the straw bagging baler consists of several key components: a feeding unit, compression chamber, hydraulic station, electrical control system, and bale discharge unit.

- The feeding unit continuously delivers straw into the compression chamber.

- The compression chamber is the core part of the machine, equipped with high-strength wear-resistant plates to ensure stable and long-term operation.

- The hydraulic station provides the necessary power and is connected to the compression chamber via high-pressure hoses.

- The electrical control system is responsible for overall monitoring and fully automated operation.

- The bale discharge unit automatically pushes the finished, compacted bales out of the machine for easy handling and downstream processes.

By integrating these systems, the straw bagging baler achieves efficient, continuous, and automated baling, making it ideal for large-scale agricultural applications such as corn straw packaging, biomass processing, and livestock bedding preparation.

Conclusion

As agriculture moves toward greater automation and efficiency, choosing the right baling method is crucial for long-term productivity and cost management. While traditional baling methods have served farmers well for decades, they are increasingly challenged by the demands of modern operations.

The straw bagging baler stands out as a fully automatic, high-performance solution that not only compresses loose materials like straw with high efficiency, but also seals them in protective bags—enhancing cleanliness, storage, transport, and moisture resistance. Compared to traditional baling, the straw bagging baler reduces labor, improves handling, and minimizes material loss.

For farms and industries seeking a smarter, cleaner, and more scalable approach to straw management, investing in a straw bagging baler is no longer just an option—it’s a competitive necessity.

-200x45.png)