“Twin shaft shredder: It’s not just a shredder – it’s the first soldier in the war against waste.”

Each year, the world creates more than 2 billion tons of solid waste, much of which is still going straight to the landfill. It can be seen from the fact that as a solid waste, its environmental sustainability has affected the entire environmental sustainable development, and unprecedented challenges have been placed on the resource management and waste disposal system of various countries, according to the United Nations Environment Programme. With the rapid progress of urbanization and changes in people’s life styles, the contents and amount of the garbage are increasingly diversified,resulting in unprecedented impact.

The treatment methods for solid wastes are still based on the disposal of wastes by burial and burning. Harmful substances can seep from waste into groundwater, and this means that waste disposal sites take up a lot of space; the high costs of incineration and the possibility of emission of toxic gases make sustainability impossible through this method. Besides, huge modern city wastes have been found to contain mixed wastes where plastics, metals, papers, and organic matter have to be separated by very tedious processes which degradation recovery recycling resources.

In view of these challenges, the Twin Shaft Shredder, as an efficient waste treatment equipment, shall become the key solution to the solid waste crisis. It can efficiently and quickly break all manner of solid wastes including metal, plastic, rubber, etc., into fine particles through strong cutting and tearing action; this in turn creates the possibility for further resource recovery and environmental protection treatments. Not only can it handle the problem of treatment for mixed wastes but also it lowers the cost of waste treatment and increases the recycling rate by a good percentage.

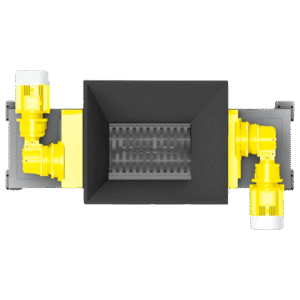

What is Twin Shaft Shredder?

Two high-strength blade shafts, which rotate synchronously, have given the name to this industrial-grade solid waste shredder. In comparison with the single-shaft or other traditional shredding equipment, twin shaft shredders are more robust in structure design; they have greater torque and stronger cutting force. They can easily manage high-hardness, large-volume, and difficult-to-handle solid waste.

The twin shaft shredder works by clamping and ripping the material with two blades that rotate in opposite directions. It applies the combined actions of shearing, squeezing, and ripping to transform big chunks or waste containing tricky impurities into much smaller pieces. This ‘biting’ method of shredding is not just efficient but also greatly reduces the chances of entanglement and thus prevents jamming up of the machine.

Its knives are usually made of high-strength alloy steel, with good wear resistance and impact resistance, and can handle a variety of complex materials, such as scrap metal, electrical housing, tires, plastic barrels, furniture, construction waste, etc. According to different application requirements, the blade shaft length, blade shape, rotation speed and screen aperture of the twin-shaft shredder can also be customized.

In short, the twin shaft shredder is like a “steel beast” that can devour all kinds of industrial and domestic waste and convert them into resource particles that are easy to handle and reuse. It is one of the core devices that promote the resource treatment of solid waste. Next, we will further explore its various roles in practical applications and the environmental and economic benefits it brings.

Core Advantages and Working Characteristics of Twin Shaft Shredders

Compared with other types of shredding equipment, dual shaft shredders have significant advantages in handling complex solid waste, which are specifically manifested in the following aspects:

High adaptability and versatility

Whether it is hard metal, soft plastic, or bulky rubber tires and waste household appliances, double-shaft shredders can easily handle it. Its powerful shear force and torque output make it the preferred equipment for handling mixed solid waste and non-recyclable garbage.

High efficiency and continuous operation capability

The twin shaft structure with variable frequency control system allows the equipment to continue to operate under high load without overheating or jamming. The material is shredded into regular or irregular fragments, which helps with subsequent classification, compression or smelting.

Strong anti-blocking and self-cleaning capabilities

Thanks to the reverse rotation design and reasonable tool arrangement, the twin shaft shredder can effectively prevent material entanglement during operation, and has a certain self-cleaning ability, reducing the frequency of manual maintenance.

Modular design for easy maintenance and upgrade

Many high-end models adopt modular structure, and the cutter and shaft can be quickly disassembled and replaced. Users can upgrade the cutting system according to different material requirements to improve shredding efficiency and service life.

Intelligent control and remote monitoring

Modern twin shaft shredders are equipped with intelligent monitoring systems, which can provide real-time feedback on parameters such as equipment load, operating temperature, and cutter wear status, and support remote control and fault warning, providing support for industrial automation and intelligent management.

It is precisely with these unique advantages that dual shaft shredders have not only become the “main player” in the garbage pretreatment link, but are also widely used in resource recycling, urban solid waste, hazardous waste, waste household appliances, plastic recycling, electronic waste and other fields. Next, we will further explore the typical application scenarios and practical value of twin shaft shredders in different industries.

Typical Application Scenarios of Twin Shaft Shredders

With its strong versatility and efficient crushing capacity, double shaft shredders play an irreplaceable role in multiple industries. The following are several representative application scenarios:

Urban solid waste treatment center

In municipal waste treatment plants, dual shaft shredders are used to initially crush domestic waste to reduce its volume for subsequent screening, compression or incineration. It is particularly suitable for processing furniture, plastic products, woven bags, kitchen waste and some construction waste, effectively alleviating the burden on landfills.

Industrial waste treatment

In the production process, factories will produce a large amount of solid waste such as scraps, waste molds, rubber blocks, pallets, paper tubes, etc. Twin shaft shredders can crush and recycle these messy and hard waste materials, improve the resource utilization rate of enterprises and reduce transportation costs.

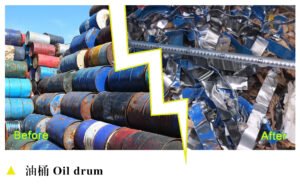

Metal recycling and regeneration industry

For high-strength materials such as scrap car shells, cables, scrap steel bars, metal barrels, etc., twin shaft shredders can cut them into small pieces for easy magnetic separation or smelting. It is one of the key equipment for scrap car dismantling and steel recycling enterprises.

Plastic and rubber recycling

All kinds of plastic bottles, pipes, films, plastic pallets and old tires can be further cleaned, granulated or refined after being processed by the double shaft shredder, forming a complete recycling process.

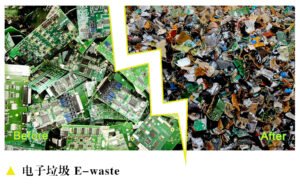

Electronic waste (E-waste) recycling

Old TVs, refrigerators, washing machines, computer motherboards and other electronic products contain metals, plastics and other recyclable materials. The twin shaft shredder can effectively disassemble the shell and internal structure, providing a convenient means for subsequent classification and extraction of valuable materials.

Hazardous waste pretreatment

Hazardous waste generated in the chemical and pharmaceutical industries, such as toxic barrel materials, expired drug packaging, laboratory waste, etc., need to be crushed and reduced before harmless treatment. The twin shaft shredder also performs well in this regard.

Through these wide application fields, it can be seen that the double-shaft shredder is not only a simple crushing equipment, but also a set of solid waste treatment solutions that integrate efficiency, safety and sustainability.

Conclusion: Tear Up Solid Waste World & Reshape A Green Future

At a time when solid waste is surging, resources are scarce, and environmental pressures coexist, the double shaft shredder, with its strong “steel appetite” and excellent adaptability, is becoming the backbone of promoting the process of solid waste resource utilization. It is not only a piece of equipment, but also a carrier of green concepts and a technical response to a sustainable future. With advanced auxiliary equipment, the double-shaft shredder builds a complete and efficient solid waste treatment chain, providing a systematic solution for urban management, industrial production, and resource recycling.

In the future, with the continuous evolution of technology and the continuous improvement of intelligence, the twin shaft shredder will play an irreplaceable role in more scenarios. Choosing high-performance double shaft shredder equipment is not only a means to improve processing capacity, but also a key step for enterprises to move towards green, intelligent and efficient development.

GIGAPA is committed to providing customers with high-quality, high-efficiency and customized solid waste treatment equipment and overall solutions. If you are facing the problem of solid waste treatment, or are looking for stable and reliable crushing equipment, we sincerely invite you to contact us. Welcome to consult, visit and purchase, and jointly start a new journey of resource recycling and low-carbon environmental protection! Let us use technology as a weapon to jointly tear apart the solid waste problem and reconstruct a renewable green world.

-200x45.png)