Vertical balers play a critical role in the recycling industry, helping businesses compress recyclable materials into compact bales for easier storage, transportation, and handling. With growing environmental awareness, stricter government regulations, and rising raw material costs, vertical balers have become indispensable for efficient waste management. This article explores the different types of vertical balers used in recycling, their features, applications, and the benefits they provide to businesses of all sizes.

What is a vertical baler?

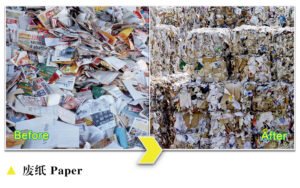

A vertical baler is a machine designed to compress recyclable materials such as cardboard, paper, plastics, and metals into dense, manageable bales. Unlike horizontal balers, which operate on a horizontal compression system, vertical balers use a vertical hydraulic ram to press materials from top to bottom.

Vertical balers are widely used in small and medium-sized recycling centres, warehouses, retail stores, and manufacturing facilities due to their compact footprint and efficiency. They are particularly effective in locations where space is limited and labour costs are a concern.

Key benefits of vertical balers include:

- Space efficiency – occupies less floor space compared to horizontal balers

- Cost-effective operation—lower energy consumption and maintenance costs

- Ease of use—simple operation suitable for small teams

- Enhanced recycling management—easy sorting and compacting of recyclable materials

Types of Vertical Balers in the Recycling Industry

Vertical balers come in various designs and configurations, each tailored for specific materials, bale sizes, and operational needs. Understanding the types of vertical balers can help recycling facilities optimize their workflow and improve efficiency.

Small Vertical Balers

Small vertical balers are compact machines designed for low- to medium-volume operations. They are ideal for retail stores, small manufacturing units, and offices where recyclable waste is generated in moderate quantities.

Features:

- Bale weight: typically 50–150 kg (110–330 lbs)

- Footprint: very small, can fit into corners or narrow spaces

- Hydraulic system: usually single-cylinder, low-power

- User-friendly operation with minimal training required

Applications:

- Cardboard and paper recycling

- Plastic film and PET bottles

- Small-scale metal scrap management

Advantages:

- Minimal floor space required

- Affordable initial investment

- Simple maintenance and low energy consumption

Small vertical balers are perfect for businesses that want to implement recycling without investing heavily in large-scale equipment. They help reduce waste volume by up to 90%, which lowers storage and disposal costs.

Medium Vertical Balers

Medium vertical balers are suitable for facilities with moderate to high volumes of recyclable materials. These balers offer larger bale sizes and stronger compression capabilities than small models.

Features:

- Bale weight: 150–500 kg (330–1,100 lbs)

- Footprint: moderate, requires dedicated space

- Hydraulic system: single- or dual-cylinder, higher pressure

- Can produce uniform bales for easier storage and transport

Applications:

- Commercial and industrial recycling

- Large retail chains with high cardboard output

- Plastic, paper, and textile recycling

Advantages:

- Higher bale density reduces transportation costs

- Durable construction for continuous operation

- Can handle mixed recyclable materials efficiently

Medium vertical balers are commonly used in distribution centers, supermarkets, and warehouses, where the volume of waste is significant, but the facility cannot accommodate a full-scale horizontal baler.

Heavy-Duty Vertical Balers

Heavy-duty vertical balers are designed for large-scale recycling operations that generate high volumes of recyclable materials. These machines are robust, powerful, and capable of producing dense bales suitable for industrial transport and processing.

Features:

- Bale weight: 500–1,500 kg (1,100–3,300 lbs) or more

- Footprint: larger, requires sufficient space

- Hydraulic system: multi-cylinder, high-pressure

- Automated or semi-automated operation available

Applications:

- Industrial manufacturing facilities

- Large-scale cardboard and paper recycling

- Metal scrap baling

- Plastic packaging and PET bottle recycling

Advantages:

- Extremely high bale density reduces transport costs

- Heavy-duty construction ensures long-term durability

- Can handle a wide variety of materials, including hard plastics and thin metals

Heavy-duty vertical balers are essential for large recycling plants and industrial facilities. They allow businesses to consolidate large quantities of waste efficiently, reducing handling time and increasing overall productivity.

Materials Processed by Vertical Balers

Vertical balers can handle a wide range of recyclable materials, making them versatile for various recycling operations. Common materials include:

- Cardboard and Paper—corrugated boxes, newspapers, office paper

- Plastics—PET bottles, shrink films, plastic containers

- Textiles—cloth scraps, fabric waste

- Metal – aluminium cans, thin sheet metals

- Composite Materials—packaging with multiple layers of materials

Choosing the right vertical baler for a specific material ensures maximum efficiency, consistent bale quality, and cost savings in storage and transportation.

Key Considerations When Choosing a Vertical Baler

When selecting a vertical baler for your recycling operation, consider the following factors:

- Material type—different materials require different bale density and compression power

- Volume of waste—small, medium, or heavy-duty balers, depending on daily output

- Space availability—vertical balers are space-efficient, but dimensions vary

- Safety features—closed-door designs, emergency stop buttons, interlocks

- Power supply – hydraulic and electric power requirements

- Ease of operation and maintenance—automated vs. manual operation

Investing in the right type of vertical baler not only improves operational efficiency but also ensures compliance with recycling regulations and workplace safety standards.

Benefits of Using Vertical Balers in Recycling

The recycling industry benefits significantly from using vertical balers, including

- Cost Savings—reduces waste volume, lowers storage and transportation costs

- Environmental Impact—encourages recycling and reduces landfill waste

- Operational Efficiency—simplifies handling and improves workflow

- Safety—minimises manual lifting and risk of injury

- Revenue Generation—compact bales are easier to sell to recycling processors

By selecting the right vertical baler, recycling centers and businesses can optimize their operations while contributing to environmental sustainability.

Conclusion

Vertical balers are vital for efficient recycling operations, enabling businesses to compress materials into dense, manageable bales. From small retail outlets to large industrial facilities, there is a vertical baler suited to every recycling need. Investing in the right type of vertical baler improves workflow efficiency, reduces costs, enhances safety, and supports environmental sustainability.

Vertical balers play a crucial role in the recycling industry by compressing recyclable materials into dense, manageable bales. Understanding the types of vertical balers, including small, medium, heavy-duty, closed-door, and open-door models, allows businesses to choose the right equipment for their operational needs.

Whether you are a small retail outlet, a medium-sized warehouse, or a large industrial facility, there is a vertical baler suited to your recycling requirements. Investing in a vertical baler not only improves efficiency and reduces costs but also helps promote environmental sustainability.

By integrating the right vertical baler into your recycling workflow, your facility can handle waste more efficiently, improve operational safety, and contribute positively to the circular economy.

-200x45.png)