A plastic granulator is one of the most essential machines in the plastic recycling and waste management industry. It plays a crucial role in size reduction, allowing manufacturers, recyclers, and processing facilities to turn plastic waste into uniform, manageable granules for further processing. Whether the material comes from rejected parts, production scrap, post-consumer waste, packaging films, or industrial residues, a plastic granulator is a core piece of equipment that ensures efficient recycling and reuse of resources.

In modern recycling lines, a plastic granulator — also known as a plastic crusher — is commonly installed after a primary shredding system such as a single-shaft shredder or twin-shaft shredder. While shredders break large plastic pieces into strips or flakes, the granulator performs the secondary crushing step, refining materials into smaller, more consistent particle sizes suitable for washing, pelletizing, or direct reuse.

This article explains in detail what a plastic granulator is used for, how it works, what industries rely on it, and why it is a vital machine for sustainable manufacturing.

How Does a Plastic Granulator Work?

A standard plastic granulator consists of several key components:

- Rotor cutter

- Stationary (reverse) cutter

- Cutting chamber

- Mechanical frame & bearing support

- Motor and gearbox

- Feeding system (manual or conveyor-fed)

- Screen mesh for particle size control

- Electrical control system

During operation, the motor drives the rotor cutters at high speed. As materials are fed into the chamber, the moving blades and fixed blades work together to cut, shear, and crush the plastics into smaller pieces. The granules are then filtered through an interchangeable screen mesh, which determines the final particle size. Different mesh sizes can be selected depending on the downstream process requirements.

One important safety principle: hard metals must not enter the crushing chamber, as they can damage blades, reduce efficiency, and cause dangerous mechanical failures.

What Is a Plastic Granulator Used For?

Plastic granulators are incredibly versatile and can be used across a wide range of applications. Below are the most common uses:

1. Recycling Waste Plastic Materials

The primary use of a plastic granulator is recycling plastic waste into reusable, uniform particles. These granules can be used for:

- Re-manufacturing plastic products

- Feeding extrusion lines

- Feeding injection molding machines

- Preparing material for pelletizing or compounding

Typical materials processed include:

- PP (polypropylene)

- PE (polyethylene)

- ABS

- PS (polystyrene)

- PVC

- PET bottles

- HDPE/LDPE films

- Nylon and engineering plastics

By reducing waste to a small size, plastic granulators help companies decrease material waste, increase recycling efficiency, and lower production costs.

2. Processing Injection Molding and Extrusion Scrap

Manufacturers often generate large amounts of scrap during injection molding, extrusion, or thermoforming. These may include:

- Runners and sprues

- Plastic lumps

- Defective products

- Edge trim

- Film roll ends

A plastic granulator converts these leftovers into uniform granules that can be reintroduced into the production line, improving material utilization and reducing expenses.

3. Cable and Wire Recycling

Plastic granulators are widely used in cable recycling lines to crush:

- Copper cable insulation

- Aluminum cable insulation

- Fiber optic cable coatings

- Rubber-based insulation materials

After granulation, the crushed material is typically sent to a cable granulator or separator, where copper or aluminum is separated from plastic for resale.

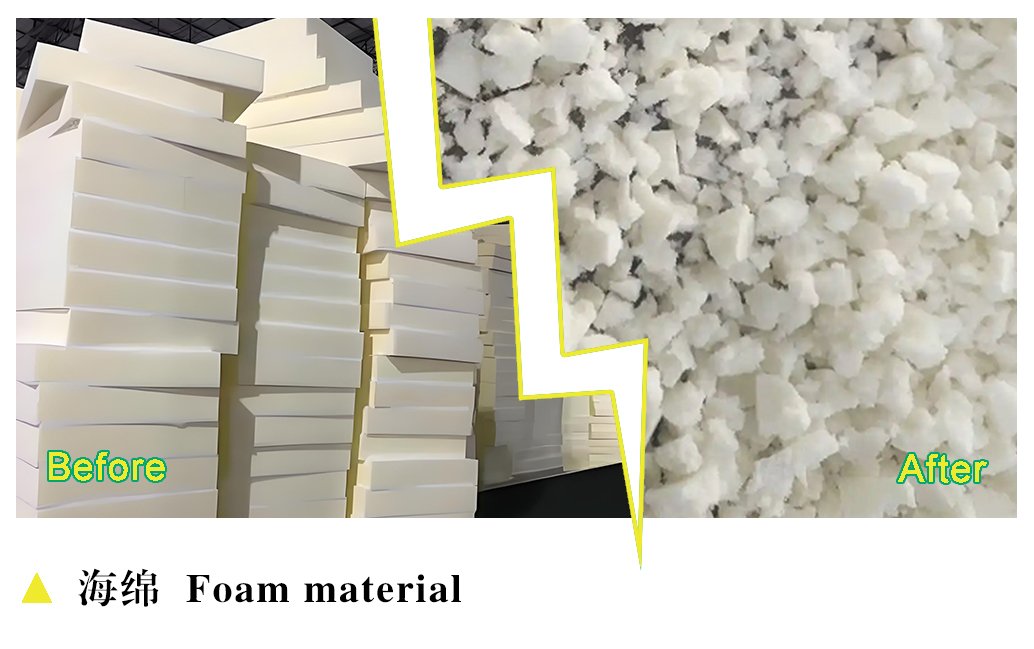

4. Rubber and Foam Material Size Reduction

Certain granulator models are specially designed to handle softer or more elastic materials, such as:

- Rubber sheets

- EVA foam

- Soft plastics

- Carpet materials

These materials require specialized rotor designs and enhanced cutting chambers to prevent clogging or overloading.

5. Electronic Waste (E-Waste) Processing

Plastic granulators are frequently used in e-waste recycling lines to crush plastic components such as:

- Computer and printer casings

- Keyboard and mouse housings

- Household appliance shells

- Television frames

- Phone plastic housings

After size reduction, materials can be sorted by density, color, or polymer type.

6. Film, Fiber, and Textile Crushing

Plastic film and fibers are typically difficult to process due to lightweight density and easy entanglement. Film granulators with specialized design features can handle:

- Agricultural films

- Packaging films

- Woven bags

- Plastic rope

- Nylon fibers

- PET straps

This helps transform soft or thin materials into consistent flakes suitable for washing and pelletizing.

Why Plastic Granulators Are Important for Recycling

1. Enhancing Efficiency of Recycling Lines

Granulators ensure that materials entering washing systems, extruders, or pelletizers have uniform size, improving output quality and reducing machine wear.

2. Reducing Material Waste

Factories can recycle internal scrap instantly, reducing raw material costs and improving sustainability.

3. Lower Transportation Costs

Bulk waste plastics occupy large volume. Granulation reduces volume, cutting transport expenses significantly.

4. Improving Product Quality

Consistent granule size enhances blending effects and stabilizes melt flow during extrusion or injection processes.

Different Types of Plastic Granulators

Depending on the material and production demand, granulators can be categorized into:

- Standard plastic granulators

- Heavy-duty granulators

- Film and fiber granulators

- Pipe and profile granulators

- Crusher-granulator combined units

- Low-speed granulators for beside-the-press recycling

Each type has its own advantages and application fields.

Choosing the Right Plastic Granulator

When selecting a granulator, consider the following factors:

- Material type (rigid, flexible, thick, thin)

- Required output capacity

- Final granule size (screen mesh)

- Moisture content and cleanliness

- Feeding method (manual, conveyor, robotic)

- Blade design and chamber structure

- Energy efficiency and noise level

- Safety protection features

A high-quality granulator improves the entire recycling system’s performance and reduces long-term maintenance costs.

Conclusion: A Key Machine for Modern Recycling

A plastic granulator is far more than just a crusher — it is an essential machine that transforms plastic waste into high-quality, reusable granules. Used across industries such as manufacturing, recycling, cable processing, e-waste management, and plastic production, it helps companies reduce waste, improve efficiency, and support sustainable development.

By integrating the right granulator into your recycling system, you can significantly increase productivity, reduce material costs, and participate in a more circular and environmentally friendly economy.

-200x45.png)