In today’s fast-paced industrial environment, efficient waste management and material handling are crucial for any business aiming to reduce costs and improve operational efficiency. For industries dealing with hazardous materials, such as metal scraps, plastics, and other recyclable waste, safety and productivity are paramount. This is where the explosion-proof vertical hydraulic baler comes into play. This heavy-duty equipment is designed to handle high-risk materials with ease while maintaining the highest safety standards. But why should you choose an explosion-proof vertical hydraulic baler for your operations? Let’s explore the key reasons.

Enhanced Safety in Hazardous Environments

The primary reason for choosing an explosion-proof vertical hydraulic baler is the enhanced safety it provides. Industries such as metal recycling, chemical processing, and waste management often handle materials that could potentially cause explosions, fires, or hazardous incidents. These materials include combustible metals, plastic wastes, and certain chemicals. A regular baler may not be equipped to handle such risks, leading to catastrophic accidents.

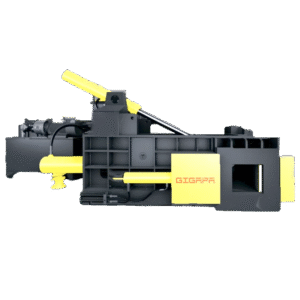

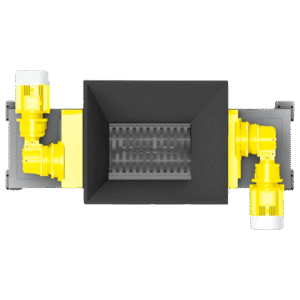

An explosion-proof baler is specifically designed with features that prevent sparks, reduce the risk of overheating, and ensure the machine remains safe to operate even in volatile environments. These machines adhere to stringent safety standards and are equipped with special enclosures, explosion-proof motors, and air ventilation systems to minimize any potential hazards.

By choosing an explosion-proof vertical hydraulic baler, you’re not just complying with industry safety regulations but also safeguarding your workers, equipment, and facility from potential explosions or fires. This minimizes downtime, reduces insurance premiums, and protects your company’s reputation.

Improved Efficiency and Productivity

In addition to safety, explosion-proof vertical hydraulic balers are designed for high-efficiency performance. These machines use hydraulic pressure to compress large volumes of waste material into compact bales, reducing the storage space required for waste and recyclable materials. The vertical design of the baler allows it to fit into smaller spaces, making it ideal for industries with limited floor space.

The explosion-proof vertical hydraulic baler can process a wide range of materials, including metal scraps, plastics, paper, textiles, and more. This versatility allows businesses to streamline their waste management operations and reduce the need for multiple pieces of equipment. The hydraulic system ensures smooth, continuous operations with minimal downtime for maintenance, leading to a significant increase in production efficiency.

Moreover, these balers can handle larger volumes of materials in less time compared to traditional manual methods. This leads to improved throughput and faster turnaround times, which is essential in industries where time and cost-efficiency are critical.

Durability and Long-Term Investment

When investing in industrial equipment, durability and longevity are always key considerations. Explosion-proof vertical hydraulic balers are built to withstand the rigors of continuous operation in demanding environments. Made from high-quality steel and designed with reinforced frames, these balers are engineered to last for many years, even under heavy usage.

These balers also require less frequent maintenance compared to other types of waste compaction equipment. The hydraulic system, which drives the baler’s pressing mechanism, is known for its reliability and ability to maintain high levels of performance over time. With proper maintenance, an explosion-proof vertical hydraulic baler can offer a long service life, providing a solid return on investment for your business.

Compliance with Industry Regulations

Many industries that handle hazardous materials are required by law to comply with specific safety and environmental regulations. Explosion-proof vertical hydraulic balers are designed to meet or exceed these regulations, ensuring that your facility stays in compliance with local, national, and international standards.

These machines are built to meet the strict guidelines set by regulatory bodies such as OSHA (Occupational Safety and Health Administration) in the U.S., ATEX (ATmosphères EXplosibles) in Europe, and other local safety regulations. Using equipment that complies with these standards not only avoids legal penalties but also demonstrates your company’s commitment to safety, which can improve your business’s reputation.

Cost-Effectiveness and Waste Reduction

One of the most compelling reasons to choose an explosion-proof vertical hydraulic baler is its cost-effectiveness. While the initial cost of purchasing such equipment may be higher than standard balers, the long-term savings outweigh this investment. The high efficiency of these machines allows businesses to compress larger volumes of waste material, reducing storage and transportation costs. Moreover, recycling these materials rather than sending them to landfills can lead to further cost savings and potential revenue from selling the compacted material.

The explosion-proof vertical hydraulic baler reduces the need for manual labor, which further cuts operational costs. With the ability to handle a variety of materials, it eliminates the need for multiple waste management systems. Over time, these savings can add up, making the equipment a highly cost-effective solution for waste handling.

Additionally, the environmental benefits of using a hydraulic baler are significant. By compressing materials into dense bales, you reduce the amount of space required for waste storage and reduce the carbon footprint associated with transporting bulky waste materials. This aligns with sustainability goals and corporate social responsibility initiatives.

Customizable Features for Specific Needs

Different industries have different needs when it comes to waste processing. The explosion-proof vertical hydraulic baler is highly customizable, allowing businesses to tailor the machine to their specific requirements. Whether you need a particular bale size, a specific hydraulic pressure setting, or enhanced automation features, these balers can be designed to fit your operational needs.

Some balers even come with automated feeding systems and advanced control panels that allow for precise adjustments and monitoring of the baling process. These customizable features make it easier to integrate the baler into your existing production line and maximize its effectiveness.

Environmentally Friendly Solution

With growing concerns about sustainability, more businesses are adopting environmentally friendly practices. Explosion-proof vertical hydraulic balers are designed to help companies minimize their environmental impact. By compressing waste materials into compact bales, these machines reduce the amount of waste that ends up in landfills, contributing to cleaner surroundings.

Recycling and repurposing materials, such as metals and plastics, help conserve natural resources and reduce the environmental footprint of your business. Choosing an explosion-proof baler shows your commitment to environmental responsibility, which can also enhance your brand’s reputation.

Conclusion

The explosion-proof vertical hydraulic baler is an essential piece of equipment for industries handling hazardous materials. With its focus on safety, efficiency, durability, and compliance with regulations, this baler offers businesses a reliable and cost-effective solution for waste management and recycling. Not only does it improve safety and productivity, but it also delivers long-term savings and environmental benefits.

If your business deals with hazardous materials and you’re looking to improve waste handling operations, investing in an explosion-proof vertical hydraulic baler is a smart decision. Contact us today to learn more about our range of balers and how we can help optimize your waste management processes.

-200x45.png)