Introduction

In the animal husbandry industry, high-quality bedding is crucial for the health and comfort of livestock. Wood shavings, widely used in horse stables, poultry farms, and other livestock facilities, provide excellent absorbency, cushioning, and odor control. To meet the growing demand for premium wood shavings, businesses rely on efficient wood shavings machines—specialized pieces of equipment designed to transform raw wood, scrap lumber, and low-value wood waste into fine, uniform shavings.

This article explores how a wood shavings machine works, its key benefits, and why it’s the preferred choice for animal bedding manufacturers worldwide.

How Does a Wood Shavings Machine Work?

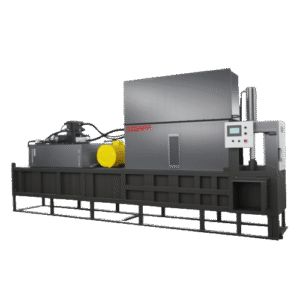

The Wood Shavings Machine operates on a highly efficient mechanical system that ensures continuous production of high-quality wood shavings. Here’s a breakdown of its working principle:

1. High-Speed Cutting Mechanism

- The main motor drives the knife shaft via V-belts, rotating at high speeds.

- Sharp blades mounted on the shaft slice through wood with precision, producing thin, consistent shavings.

2. Reciprocating Feed System

- A geared motor powers a chain-and-sprocket mechanism, moving the feed box back and forth.

- As the wood inside the feed box moves against the rotating blades, it gets evenly shaved from all sides.

3. Automated Discharge

-

Freshly cut wood shavings fall onto a conveyor belt below, which transports them out for collection and packaging.

This seamless process allows the machine to handle various wood types, including:

✔ Raw logs

✔ Scrap wood (off-cuts, pallets, branches)

✔ Industrial wood waste (sawmill residues, plywood trimmings)

Why Choose Our Wood Shavings Machine?

High Efficiency & Continuous Production

- Capable of processing large volumes of wood with minimal downtime.

- Ideal for businesses supplying horse bedding, poultry farms, and pet care companies.

Cost-Effective Raw Material Usage

- Converts low-value wood waste into profitable bedding material.

- Reduces disposal costs for sawmills and woodworking shops.

Superior Shaving Quality

- Produces soft, fluffy, and dust-free shavings—perfect for animal comfort.

- Adjustable blade settings allow customization of shaving thickness.

Durability & Low Maintenance

- Built with heavy-duty steel for long-lasting performance.

- Simple design ensures easy servicing and part replacement.

Global Demand for Wood Shavings

- Horse stables, livestock farms, and pet bedding manufacturers constantly seek high-quality wood shavings.

- Export opportunities in Europe, North America, and Asia for bulk suppliers.

Applications of Wood Shavings

The shavings produced by this machine are widely used in:

🐴 Horse Bedding

- Provides a soft, absorbent layer that reduces ammonia buildup.

- Preferred by equestrian centers and racehorse trainers.

🐔 Poultry & Livestock Bedding

- Helps maintain dry, hygienic conditions in chicken coops and pig pens.

- Minimizes bacterial growth and odors.

🛏️ Small Animal & Pet Bedding

- Safe and comfortable for rabbits, hamsters, and reptiles.

- Dust-free options are available for sensitive animals.

🌱 Horticulture & Composting

- Used as mulch to retain soil moisture.

- Biodegradable and eco-friendly.

Conclusion

A wood shavings machine is an indispensable tool for animal bedding manufacturers, sawmills, and wood recyclers. Its ability to turn waste wood into valuable, high-demand products makes it a smart investment for entrepreneurs looking to enter the lucrative animal bedding market.

If you’re searching for a reliable, high-output wood shavings machine, our industrial-grade models deliver efficiency, durability, and premium shaving quality.

-200x45.png)