The door-type metal briquetting machine, an industrial equipment that combines modern mechanical technology with environmental protection concepts, is reshaping the new form of metal with its huge force of 10,000 tons. In the broad arena of metal recycling and reuse, it plays a pivotal role, not only greatly improving the utilization efficiency of metal resources but also promoting the vigorous development of the circular economy. This article will explore in depth, from multiple dimensions, how this equipment can inject new vitality into the metal industry in its unique way.

What is Door-Type Metal Briquetting Machine

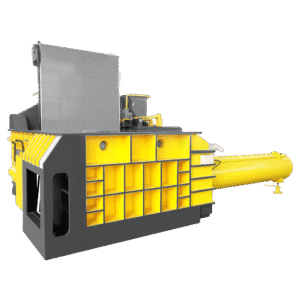

The door-type metal briquetting machine is a hydraulic device for efficiently processing scrap metal. It can compress various thin scrap steel, aluminum chips, copper sheets and other metal scraps into high-density blocks, greatly reducing the volume and facilitating transportation and recycling. It adopts an open-top design, which is convenient for feeding. The hydraulic system can provide strong pressure ranging from tens of tons to thousands of tons, which can compress loose metal to 1/3 of the original volume or even smaller. It is particularly suitable for use in scrap recycling stations, metal processing plants and automobile dismantling industries. When working, just put the scrap metal into the compression chamber, the hydraulic cylinder drives the pressure cover to press down and form, and the briquette is automatically pushed out and can be bundled or shipped. This equipment not only saves storage space, but also increases the sales value of scrap materials. It is an essential tool for modern scrap metal recycling.

Working Principle of Door-Type Metal Briquetting Machine

As the name implies, door-type metal briquetting machine is a device that can compress and pack scattered metal waste (such as scrap steel, scrap aluminum, scrap copper, etc.) into regular shapes (such as rectangular blocks). Its working principle is mainly based on the hydraulic transmission system, which delivers hydraulic oil to various actuators (such as main pressure cylinder, door cover cylinder, door opening cylinder, etc.) through the hydraulic pump, thereby driving various parts of the equipment to complete a series of actions such as pre-compression, cover closing, compression, pressure maintenance, and pressure relief.

Specifically, when the metal waste is put into the material box, the door cover rotates and closes under the action of the cylinder to form a closed compression chamber. Subsequently, the main pressure cylinder starts to work and compresses the metal waste into a tight block. During the compression process, the hydraulic system will automatically adjust according to the preset pressure value to ensure that the quality and density of the block meet the requirements. After the compression is completed, the door opening cylinder is activated, the door cover is opened, the block is pushed out of the material box, and the entire packaging process is completed.

Composition Structure

The door-type metal briquetting machine achieves efficient compression processing of scrap metal through the coordinated work of six core components:

- Box—a solid steel structure frame that bears the overall weight of the equipment and ensures stable operation of the compression process.

- Door cover—retractable heavy-duty cover that opens when feeding and closes to form a sealed compression chamber during compression to ensure safe operation.

- Hydraulic cylinder and pressure plate—core power components. The hydraulic cylinder drives the pressure plate to generate tens to thousands of tons of pressure, directly pressing the loose metal into a high-density block.

- Hydraulic system—consists of a motor, oil pump, valve group and pipeline, providing a stable high-pressure oil flow for the cylinder, which determines the compression capacity and efficiency of the equipment.

- Compression chamber—a closed space for metal forming, designed with special wear-resistant materials, can withstand high-intensity extrusion friction for a long time.

- Electrical system—PLC or relay control center, realizing intelligent operation of automatic feeding, compression, pressure holding, discharging and other processes.

The Door Type is Cleverly Designed, Stable and Durable

It uses hydraulic principle to cold press to produce high-density metal blocks, without adhesives and without changing the properties of the metal.

The main cylinder compression force of this equipment ranges from 100-1500t, and the motor power ranges from 30-300kw to meet the needs of different customers.

Types of Door-Type Metal Briquetting Machine

Based on the different structures, functions and application scenarios, door-type metal briquetting machine can be divided into many types. Among them, according to the pressure size, they can be divided into small, medium and large briquetting machines; according to the baling method, they can be divided into vertical, horizontal and side briquetting machines; according to the degree of automation, they can be divided into manual, semi-automatic and fully automatic briquetting machines.

Taking the GFB-P door-type metal briquetting machine as an example, it is a typical large horizontal cold bundle baling equipment. The equipment adopts a rotary cover structure with a large material box opening for easy filling. At the same time, because it adopts hydraulic drive, it has the characteristics of high working efficiency and high baling pressure. It can easily pack waste steel into rectangular blocks, which is very suitable for waste steel recycling and reuse industry.

Material Handling Comparison

Conclusion

The door-type metal briquetting machine has become an indispensable tool in the scrap metal recycling industry with its solid structural design, efficient hydraulic compression system and intelligent operation control. Whether it is to improve storage efficiency, reduce transportation costs, or increase the sales value of scrap materials, it can bring significant economic benefits to enterprises. With the growing demand for resource recycling, investing in such an efficient and durable metal briquetting machine is undoubtedly a wise choice to promote enterprises to reduce costs and increase efficiency and achieve green and sustainable development. Choosing it means choosing a more efficient and environmentally friendly way to handle scrap metal!

-200x45.png)