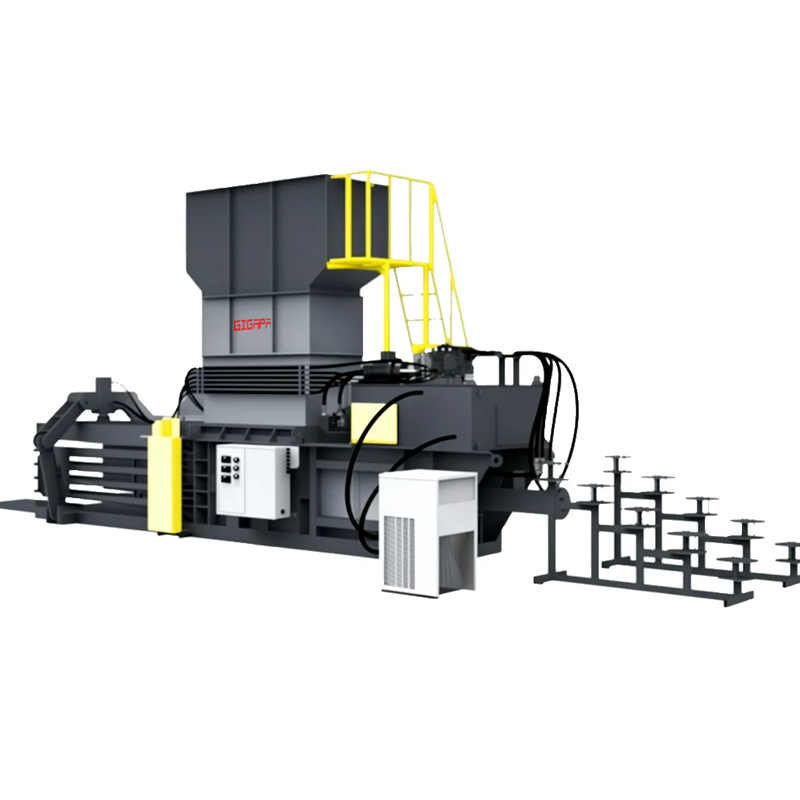

Efficient and reliable waste reduction is a critical aspect of modern industrial operations. The heavy-duty twin-shaft shredder is engineered to tackle the most demanding shredding tasks across a wide range of industries. Whether you’re dealing with bulky waste, construction debris, metal drums, rubber, wood, e-waste, or even hazardous materials, this twin shaft shredder is designed to deliver high torque, low speed, and powerful performance—day in and day out.

Built for large-scale, continuous operation, this robust shredding system transforms complex and oversized materials into manageable, uniform pieces suitable for recycling, incineration, or disposal. If your facility requires high-capacity waste processing with minimal downtime, the heavy-duty twin-shaft shredder is the perfect solution.

What Is a Heavy-Duty Twin Shaft Shredder?

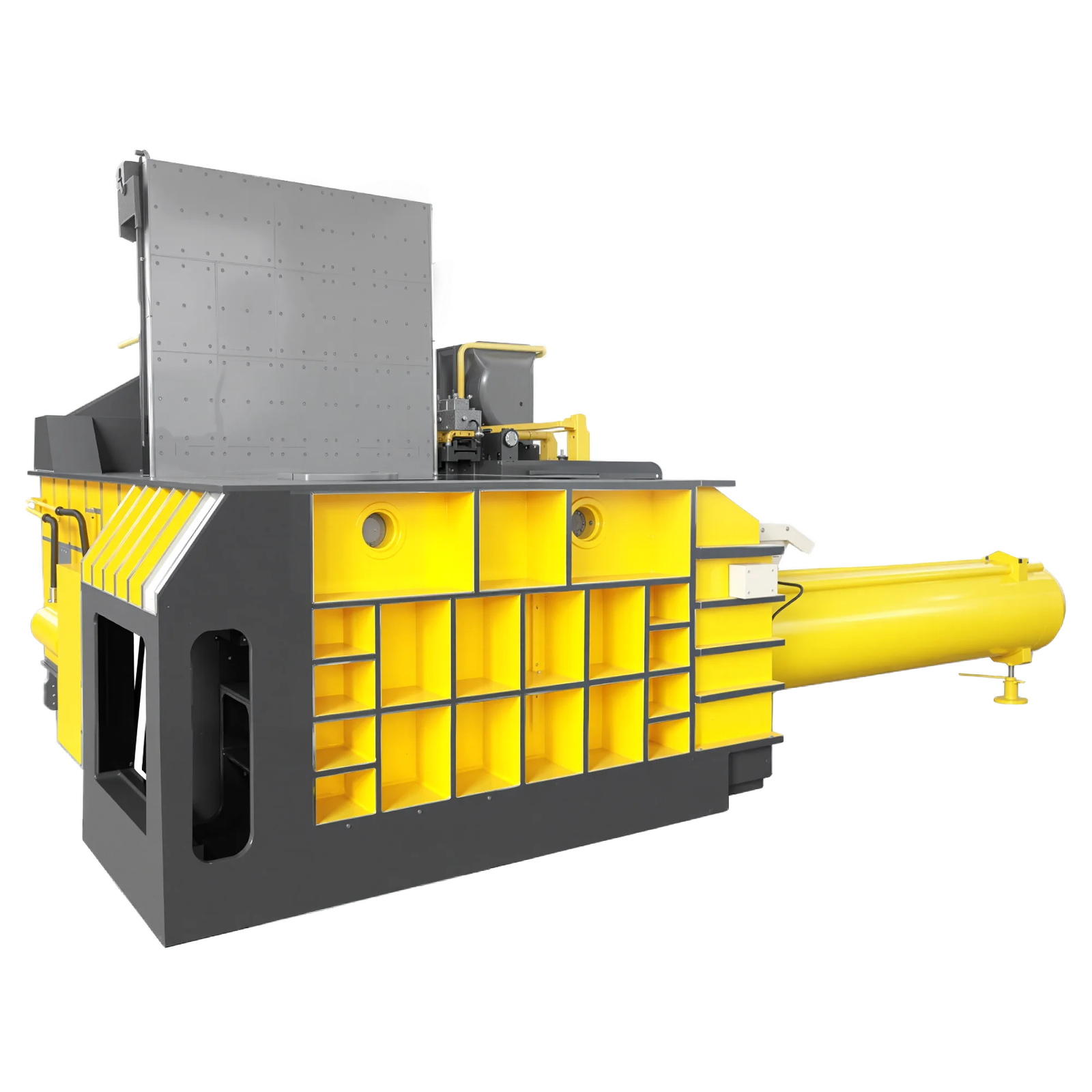

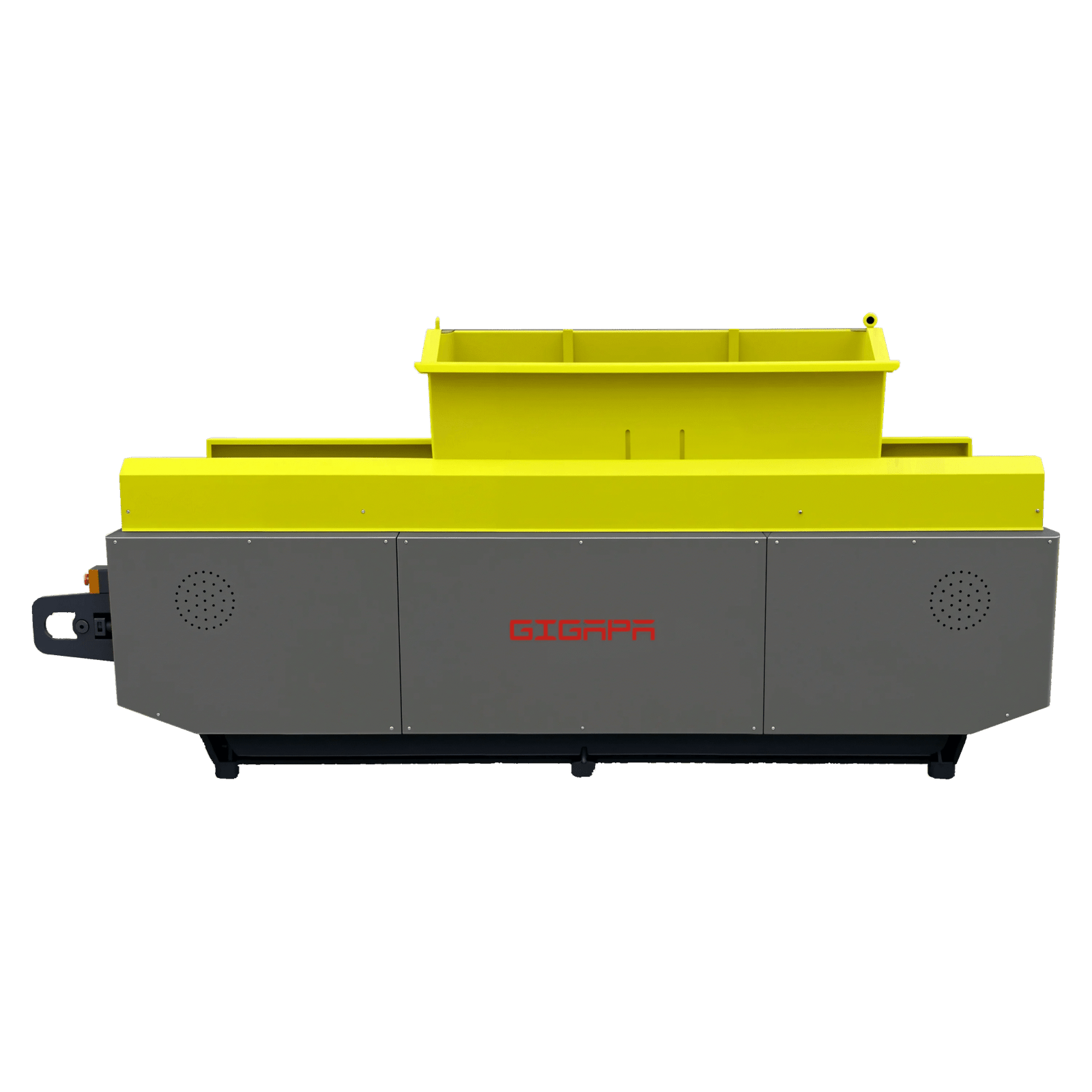

A Twin Shaft Shredder is an industrial-grade machine that utilizes two parallel shafts equipped with counter-rotating blades. These blades grip, tear, and shear materials into smaller pieces using torque rather than high-speed cutting. Unlike single shaft shredders, twin shaft systems are ideal for coarse shredding of materials that are too large, tough, or contaminated for finer processors.

This particular heavy-duty model is constructed with reinforced steel housing, hardened alloy cutters, and an intelligent control system, making it well-suited for the most aggressive applications.

Core Features of the Heavy-Duty Twin Shaft Shredder

High-Torque, Low-Speed Operation

The shredder operates at low rotation speeds but delivers high torque. This design ensures energy efficiency, quiet operation, and reduced dust and heat generation—while still tearing through hard or bulky waste with ease.

Rugged Construction for Long-Term Use

The entire frame is made from heavy-duty welded steel, reinforced with anti-vibration pads and protective panels. It’s built to resist deformation and wear in high-stress environments.

Wear-Resistant Cutting Blades

Each shaft is lined with replaceable, high-grade alloy steel cutters that are heat-treated for wear resistance and long service life. Different cutter configurations are available depending on your material type.

Smart Control System (PLC)

An integrated PLC control system enables automatic start/stop, reverse rotation in case of overloading, and emergency stop functionality. The system also monitors blade torque, speed, and motor temperature in real time.

Customizable Sizing and Throughput

Depending on your shredding capacity requirements, the machine can be customized for motor power, shaft length, cutter thickness, and chamber size.

Auto-Reverse Protection

To prevent jamming, the shredder automatically reverses the shaft direction when it detects a material blockage, then resumes normal operation once the material is cleared.

Benefits of Using a Heavy-Duty Twin Shaft Shredder

1. Versatility Across Materials

From plastic barrels to car tires, aluminum scrap, and even electronic waste, this shredder can handle a broad spectrum of difficult-to-process materials. It’s an all-in-one solution for complex waste streams.

2. Increased Operational Efficiency

Large capacity and continuous feed capability help boost overall productivity. With minimal supervision required, operators can focus on other tasks while the shredder runs in the background.

3. Improved Safety and Compliance

By reducing waste size, the machine helps ensure compliance with local and international waste processing regulations, while also minimizing fire hazards and contamination risks.

4. Support for Recycling and Waste Recovery

The shredded output is perfect for further processing, whether it’s sorting, incineration, or direct recycling—helping companies minimize landfill use and recover valuable secondary materials.

5. Lower Maintenance Costs

Thanks to its rugged build and automatic overload protection, downtime is minimized. Modular parts design also allows for quick replacement of wear components.

Typical Applications and Material Types

The Heavy-Duty Twin Shaft Shredder is widely used in the following industries:

- Municipal Waste Processing – Household garbage, organic waste, bulky items

- Construction & Demolition – Wood, concrete pieces, insulation boards

- Scrap Metal Recycling – Aluminum sheets, steel drums, metal shavings

- Plastic Industry – Plastic containers, pipes, molded parts

- Rubber & Tires – Car tires, conveyor belts, rubber sheets

- E-Waste Management – Circuit boards, cables, small appliances

- Textile & Fabric Shredding – Waste clothing, industrial textiles

- Agricultural Waste – Biomass, coconut shells, sugarcane waste

Whatever your sector, if your material is tough, tangled, or oversized, this machine can handle it.

Customization Options

We understand that every application is different. That’s why we offer multiple custom features:

- Motor power options (30kW to 200kW+)

- Cutter thickness (15mm–100mm) and material type

- Chamber dimensions tailored to material size

- Output conveyor integration

- Dust collection interface

- Remote monitoring and automated alert systems

Our engineers work with you to create the right configuration for your waste type, volume, and processing goals.

Certifications and Quality Assurance

Our machines are built to meet stringent international standards:

- CE Certified

- ISO 9001 Compliant

- Factory tested before shipment

- Includes inspection reports and test videos

We use only industry-grade components from trusted global brands (Siemens, SKF, etc.) to ensure reliability and performance.

After-Sales Service and Technical Support

Your investment is protected by our robust support system:

- Professional installation guidance (on-site or remote)

- Operator training and maintenance instructions

- Spare parts availability and fast delivery

- 24/7 customer support line and video troubleshooting

- Long-term service contracts for industrial clients

Conclusion

The heavy-duty twin-shaft shredder is not just another industrial shredder—it’s a reliable partner in waste reduction, resource recovery, and environmental responsibility. Its powerful build, automation features, and application versatility make it ideal for businesses that handle large or difficult waste materials.

Whether you’re operating a municipal waste facility, a recycling plant, or a manufacturing line, this shredder provides the strength and intelligence your operation needs.

-200x45.png)