In the modern metal processing industry, efficiency and sustainability are increasingly becoming top priorities. One of the biggest challenges faced by manufacturers is how to handle the large volumes of loose metal chips generated during machining, turning, drilling, and milling operations. These chips, whether from cast iron, steel, aluminum, or other alloys, are bulky, difficult to store, costly to transport, and pose significant risks of environmental pollution due to residual cutting fluids.

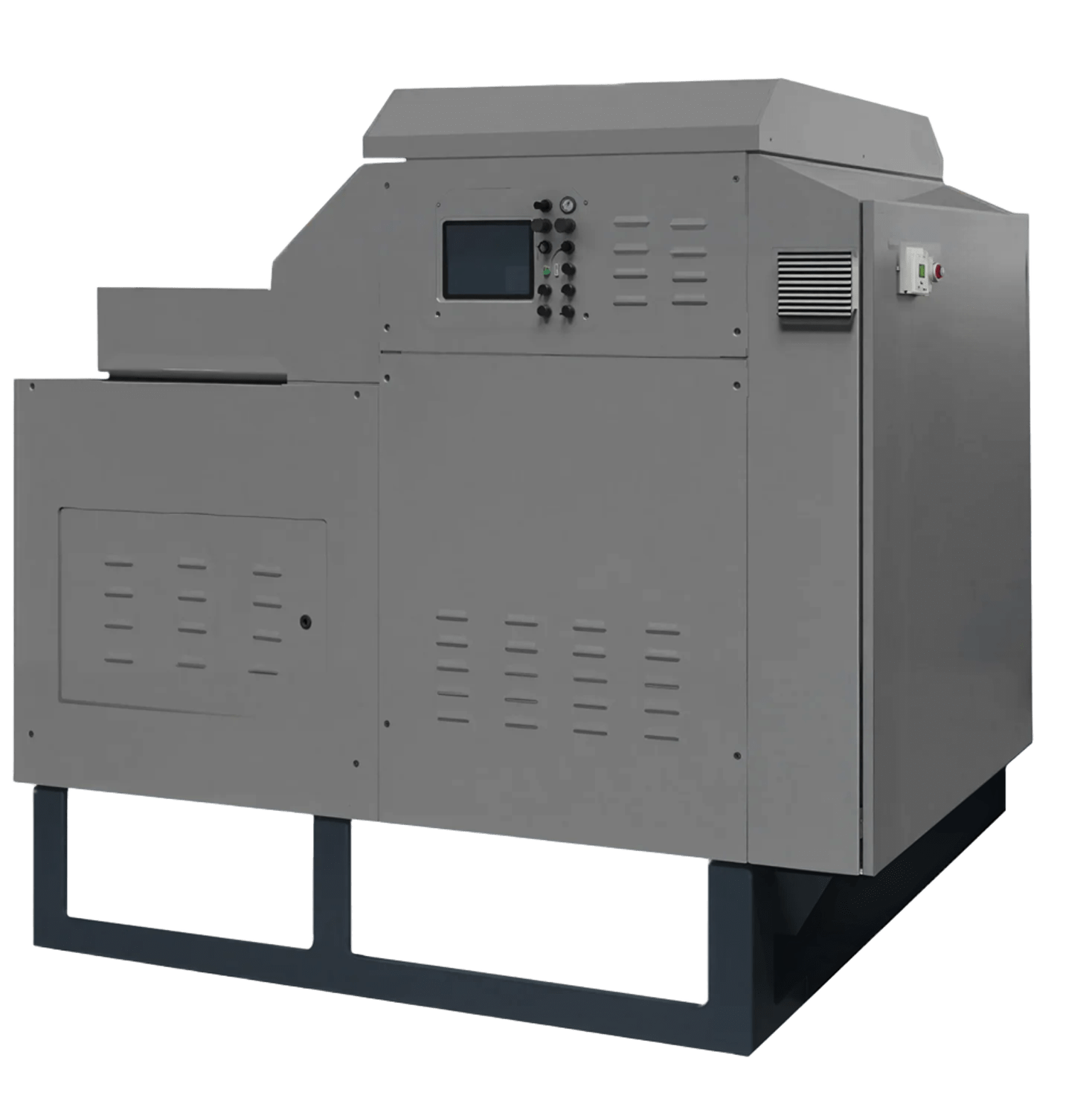

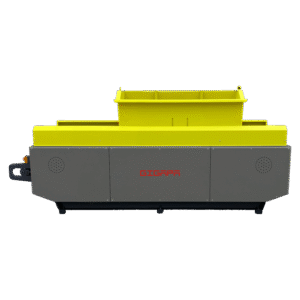

The metal chip briquetting machine offers a powerful and sustainable solution. By transforming loose metal chips into dense briquettes, it converts what was once considered industrial waste into a high-value resource that can be easily stored, transported, and reused in smelting. Equipped with intelligent automation systems, advanced hydraulic compression, and environmentally friendly features, this machine represents a breakthrough in metal recycling technology.

Integrated Design and Working Principle

The metal chip briquetting machine adopts an integrated “crushing–conveying–pressing” design. The process begins with a feeding elevator that transfers curled or lumpy metal chips into a single-shaft crusher. The crusher breaks down the chips into uniform granules, ensuring consistency in subsequent compaction. The material is then conveyed into the briquetting chamber.

Advanced Siemens or Schneider PLC control systems monitor key parameters in real time, including pressure, temperature, and material flow. The system can automatically adjust pressing pressure and cycle time based on the type of chip being processed—for example, cast iron chips require different settings compared to steel chips. This smart control ensures optimized briquette density, energy efficiency, and production safety.

Core Technical Features

1. High-Efficiency Compression

The metal chip briquetting machine utilizes direct cold pressing with extremely high hydraulic pressure, often exceeding 1,250 tons. This compression technology can reduce the volume of loose chips by more than 90%, producing dense round or rectangular briquettes. The compression ratio is significant, enabling factories to drastically reduce storage requirements and lower downstream transportation costs.

2. Environmentally Friendly Design

The briquetting process is carried out in a sealed environment, effectively preventing the leakage of cutting fluids and other industrial liquids. The metal chip briquetting machine is equipped with a waste fluid collection and filtration system, allowing coolant and lubricants to be recycled and reused. This closed-loop system reduces pollution and supports compliance with increasingly strict global environmental regulations.

3. Full Automation

The fully automatic metal chip briquetting machine integrates feeding, compaction, and discharge without the need for constant operator intervention. Metal chips are automatically pushed into the die cavity, compacted with hydraulic pressure, and ejected as finished briquettes. This level of automation reduces manual labor, enhances workplace safety, and ensures stable, high-volume production.

4. Durability and Reliability

The hydraulic system is designed using advanced international technology, ensuring long-term stability and durability. Built-in fault diagnosis and alarm functions increase machine reliability and minimize downtime. For industries where production continuity is critical, this durability translates into substantial operational advantages.

Value Creation Through Briquetting

The advantages of briquetting extend far beyond simple volume reduction. The transformation of loose metal chips into briquettes creates measurable economic, operational, and environmental benefits.

1. Reduced Storage and Transportation Costs

Loose metal chips typically have a bulk density of only 0.2–0.5 tons per cubic meter. After briquetting, this density increases dramatically to around 5.5 tons per cubic meter. For example, an automotive component factory processing 5,000 tons of chips annually reduced transportation costs from 1.2 million RMB to just 150,000 RMB after adopting briquetting technology.

2. Improved Smelting Efficiency

Dense briquettes melt faster in furnaces, shortening melting time by up to 20%. Energy consumption drops by around 15%, and metal recovery rates increase by 10–20%. A steel plant that implemented this solution reported savings of more than 1,000 RMB per ton in casting costs, highlighting its potential for large-scale cost optimization.

3. Significant Environmental Benefits

The briquetting process requires no chemical additives, reducing dust emissions by up to 80%. Equipped with waste liquid recovery, the system can cut annual wastewater discharge by more than 2,000 tons. The metal chip briquetting machine complies with stringent European environmental standards, making it highly suitable for manufacturers that must meet global sustainability requirements.

Applications Across Industries

The metal chip briquetting machine is widely applicable in industries where machining operations generate large volumes of chips:

- Automotive Manufacturing: Factories producing engine blocks, gear housings, and transmission components often generate thousands of tons of cast iron chips annually. Briquetting provides a direct path to recycling.

- Steel and Foundry Plants: High-density briquettes improve furnace efficiency, reduce slag, and enhance overall metallurgical recovery rates.

- Aerospace and Precision Engineering: Materials such as titanium and aluminum alloys are expensive. Briquetting allows efficient recycling of chips, reducing material waste and costs.

- Heavy Machinery and Construction Equipment: Large machining shops can handle bulky steel chips more easily with compact briquettes.

Contribution to Sustainable Manufacturing

Sustainability is no longer an optional feature—it is a competitive requirement. By integrating a metal chip briquetting machine, companies not only save money but also demonstrate their commitment to green manufacturing.

Key sustainability contributions include:

- Lower carbon footprint through reduced transportation needs.

- Higher recycling rates for valuable metals.

- Minimized industrial wastewater and dust emissions.

- Alignment with ISO 14001 and similar environmental management standards.

In addition, briquetting supports the circular economy by ensuring that waste chips are transformed into reusable raw materials instead of being disposed of in landfills.

Market Outlook and Future Trends

The global demand for metal chip briquetting machines is expected to grow significantly over the next decade. Several factors are driving this trend:

- Stricter Environmental Regulations: Governments worldwide are enforcing higher standards on industrial waste management.

- Rising Raw Material Costs: Recycling metal chips reduces dependency on virgin raw materials, a growing concern as ore prices fluctuate.

- Industry 4.0 and Smart Manufacturing: Integration of sensors and IoT enables predictive maintenance and real-time data monitoring, further improving machine performance.

- Global Sustainability Initiatives: Large corporations are prioritizing supply chain partners that demonstrate eco-friendly practices, giving early adopters of briquetting technology a competitive advantage.

Conclusion

GIGAPA metal chip briquetting machine is more than just a piece of recycling equipment—it is a strategic investment for modern manufacturers. By compacting loose chips into dense, high-value briquettes, the machine reduces storage and transportation costs, improves furnace efficiency, minimizes environmental impact, and supports long-term sustainability goals.

For industries ranging from automotive to aerospace, adopting briquetting technology means turning unavoidable by-products into profitable resources. As global regulations tighten and sustainability becomes a central pillar of industrial competitiveness, the role of metal chip briquetting machines will only become more critical in shaping the future of green manufacturing.

-200x45.png)