Running a scrap yard today requires far more than simply collecting discarded metal and reselling it. With competition intensifying, recycling demands growing, and sustainability goals becoming more urgent, efficiency has become the key driver of profitability. In this context, the scrap metal shredder has emerged as a powerful solution. Known for its efficiency and environmentally friendly design, it plays a crucial role in transforming how scrap yards handle metal waste. Whether you are a small recycler or a large-scale operation, the right shredder can reduce costs, optimize workflows, and significantly boost your return on investment. Beyond profitability, it also supports the green development of the metal recycling industry by making waste management more sustainable.

In this article, we’ll explore how a scrap metal shredder helps streamline operations, boost productivity, and improve profitability, while also meeting environmental and regulatory requirements.

What is a Scrap Metal Shredder?

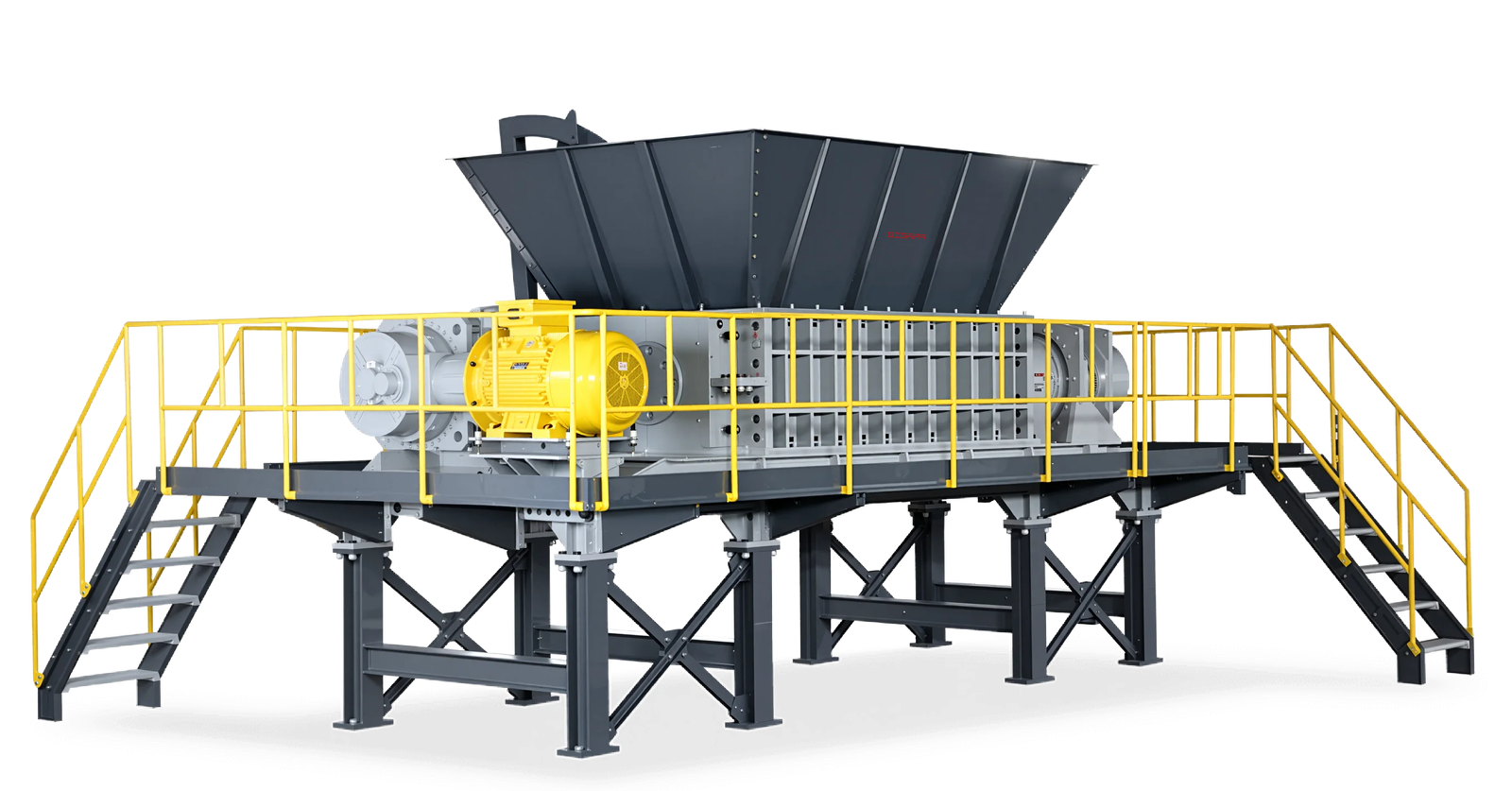

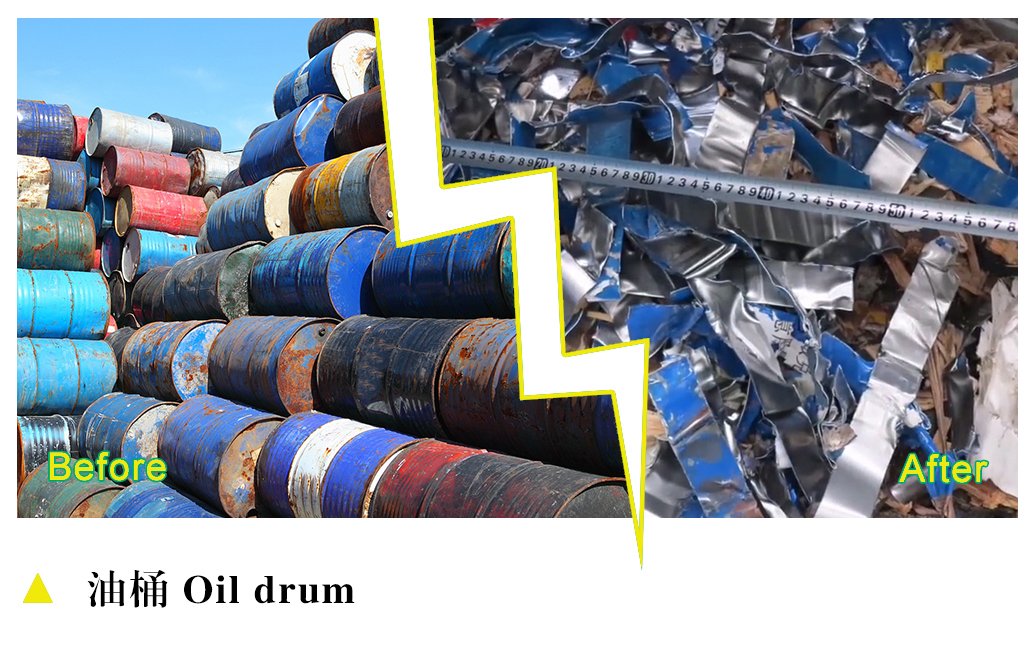

A scrap metal shredder is a powerful machine designed to break down bulky and irregular pieces of scrap metal into smaller, uniform fragments. Unlike manual cutting or less advanced equipment, shredders can process large quantities of metal quickly and efficiently. These machines are engineered to handle everything from old vehicles, household appliances, and construction debris to industrial scrap, turning them into manageable sizes for recycling or resale.

Scrap metal shredders come in various types, including single-shaft, dual-shaft, and hammer mill shredders, each designed for specific materials and volumes. Choosing the right shredder depends on your yard size, the types of metals you process, and your long-term business goals.

How the Scrap Metal Shredder Works

The scrap metal shredder is a modern, high-performance machine designed to simplify scrap processing. Its working principle combines heavy-duty blades, a robust rotor system, and an intelligent control unit to ensure consistent output. Scrap metal is first fed into the shredder through a wide intake hopper, where rotating cutters grip and tear down bulky items such as steel beams, car frames, and industrial offcuts. The material then passes through precisely engineered cutting chambers that reduce it into uniform pieces.

What sets the scrap metal shredder apart is its automated monitoring system, which adjusts blade pressure and speed based on the density and toughness of the input material. This prevents blockages, minimizes wear and tear, and ensures smooth continuous operation. Additionally, integrated magnetic separation units can be added to instantly separate ferrous metals from non-ferrous, allowing for streamlined sorting right after shredding. The result is a steady flow of clean, recyclable metal pieces ready for resale or smelting, with minimal downtime and maximum efficiency.

Benefits of Using a Scrap Metal Shredder

1. Improved Efficiency and Speed

One of the biggest advantages of a scrap metal shredder is the significant boost in processing speed. Manual methods or outdated equipment can slow down operations, leading to bottlenecks. With a modern shredder, you can process tons of material per hour, ensuring your scrap yard keeps up with customer demand.

2. Increased Scrap Value

Shredded scrap metal often fetches a higher market price. Why? Because shredded metal is easier to melt, transport, and reuse in manufacturing. Buyers and recycling plants prefer pre-shredded material, meaning you can secure better deals and maximize profitability by using a shredder.

3. Reduced Transportation Costs

Large, bulky scrap can take up excessive space during transport, resulting in fewer materials per truckload and higher logistics costs. A scrap metal shredder compresses materials into smaller pieces, allowing you to transport more in one trip and lower overall expenses.

4. Enhanced Safety

Handling oversized or irregular scrap with manual tools can be dangerous for workers. A shredder reduces these risks by automating the breakdown process. Workers spend less time manually cutting and sorting, creating a safer work environment.

5. Compliance with Environmental Standards

Many regions have strict recycling and waste management regulations. A scrap metal shredder helps your business stay compliant by ensuring proper size reduction, sorting, and preparation of recyclable materials. This reduces the risk of fines and strengthens your reputation as an environmentally responsible operation.

How a Scrap Metal Shredder Streamlines Scrap Yard Operations

Streamlined Sorting Process

Once metals are shredded, it becomes easier to separate ferrous from non-ferrous materials using magnetic systems. This streamlined sorting not only saves time but also ensures higher purity levels in the recycled materials, which increases market value.

Optimized Storage

Shredded metal occupies less space, which optimizes your yard’s storage capacity. Instead of dedicating vast areas to unprocessed scrap, you can neatly store shredded material, keeping your yard organized and easier to manage.

Faster Turnaround Times

When customers deliver scrap to your yard, fast service is key to satisfaction and repeat business. By processing metals immediately with a scrap metal shredder, you can reduce wait times and enhance your reputation for efficiency.

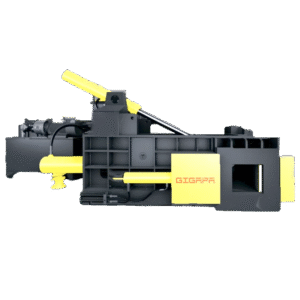

Integration with Other Systems

Modern shredders can be integrated with conveyors, magnetic separators, and balers. This creates a fully automated workflow, reducing labor requirements and minimizing errors while increasing output consistency.

Choosing the Right Scrap Metal Shredder

When deciding to invest in a scrap metal shredder, consider the following factors:

- Capacity Needs – Estimate the average tons of scrap you process daily to choose a machine with adequate throughput.

- Type of Materials – Consider whether you primarily handle light metals, heavy steel, or mixed scrap, as different shredders are optimized for specific materials.

- Energy Efficiency – Look for shredders that provide maximum output with minimal energy consumption to save on operational costs.

- Durability and Maintenance – Choose models with strong blades, reinforced housing, and easy access for maintenance. This ensures longevity and reduces downtime.

- Supplier Support – Work with a reliable supplier who offers installation, training, and after-sales support.

Financial Benefits of Investing in a Scrap Metal Shredder

A scrap metal shredder should not be viewed as a cost, but rather as a long-term investment. While the upfront price may seem high, the financial benefits often outweigh the initial expense:

- Higher Scrap Value – Shredded metals are in higher demand, securing better deals.

- Lower Operating Costs – Reduced manual labor and transportation costs save money.

- Faster ROI – Many scrap yard owners report achieving a return on investment within just a few years due to increased efficiency and profitability.

Conclusion

In today’s competitive recycling industry, efficiency and profitability are the keys to success. A scrap metal shredder is not just a machine; it is a transformative tool that streamlines scrap yard operations, reduces costs, and boosts revenue. From faster processing and improved safety to higher scrap value and compliance with environmental regulations, the benefits are undeniable.

If you are looking to scale your business, investing in a scrap metal shredder is one of the smartest decisions you can make. By optimizing workflow and maximizing profits, you ensure your scrap yard stays competitive while contributing positively to the environment.Ready to take your scrap yard to the next level? Explore GIGAPA range of high-performance GTS-E dual shaft shredders designed to meet the needs of modern recycling operations. Contact us today for a customized quote and start streamlining your operations immediately!

-200x45.png)