A fully automatic horizontal baler for straw has become an essential solution in modern agriculture as the industry places increasing emphasis on efficient biomass recycling and sustainable resource utilization. Every year, millions of tons of agricultural straw are generated from crops such as wheat, rice, corn, barley, and rapeseed. Without proper processing, this large volume of straw waste can lead to environmental pollution, inefficient land use, and rising disposal costs. As a result, fully automatic horizontal balers are widely adopted by agricultural enterprises, biomass power plants, recycling centers, and large-scale farms to improve efficiency and maximize resource value.

What Is a Fully Automatic Horizontal Baler for Straw?

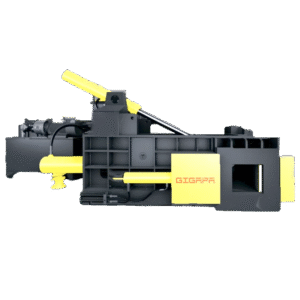

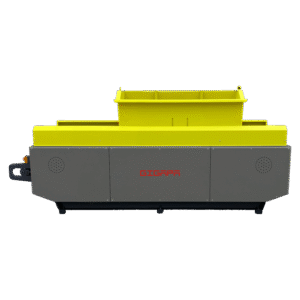

A fully automatic horizontal baler for straw is an industrial-grade baling machine that uses hydraulic pressure to compress straw materials into compact rectangular bales. Unlike vertical balers or semi-automatic machines, horizontal balers are designed for continuous, high-capacity operation, making them ideal for handling large volumes of loose agricultural biomass.

The term “fully automatic” refers to the complete automation of the baling process, including material feeding, compression, bale tying (usually with wire or plastic strapping), bale length control, and bale discharge. This high level of automation minimizes labor requirements and ensures consistent bale quality.

Why Is Straw Baling Important?

Environmental Protection

Unmanaged straw waste is often burned in open fields, causing severe air pollution and greenhouse gas emissions. Baling straw provides an environmentally friendly alternative by enabling recycling, reuse, or energy recovery.

Cost Reduction

Loose straw occupies a large volume, leading to high transportation and storage costs. By compressing straw into dense bales, a horizontal baler can reduce volume by up to 80%, significantly lowering logistics expenses.

Resource Utilization

Baled straw can be reused in multiple industries, including biomass energy generation, animal bedding, mushroom cultivation, paper production, and building materials. Efficient baling is the first step toward value-added utilization.

Working Principle of a Fully Automatic Horizontal Straw Baler

- Material Feeding

Loose straw is fed into the baler through a conveyor belt, air feeding system, or manual loading, depending on the production line design. - Pre-Compression and Main Compression

Hydraulic cylinders push the straw horizontally into the compression chamber, gradually increasing pressure until the desired bale density is achieved. - Automatic Bale Tying

Once the preset bale length and density are reached, the machine automatically ties the bale using wire or PET strapping. - Bale Discharge

The finished bale is automatically pushed out of the baling chamber, ready for stacking, storage, or transportation. - Continuous Operation

The system immediately starts forming the next bale, enabling uninterrupted, high-efficiency production.

Key Advantages of Fully Automatic Horizontal Balers for Straw

-

High Efficiency and Throughput

Fully automatic horizontal balers are designed for large-scale operations, with processing capacities ranging from several tons per hour to over 30 tons per hour, depending on the model and straw type.

-

Labor Savings

Automation significantly reduces the need for manual intervention. One operator can oversee the entire baling line, lowering labor costs and improving workplace safety.

-

Consistent Bale Density

Advanced hydraulic systems and PLC controls ensure uniform compression, resulting in bales with consistent size, weight, and density. This is critical for downstream processing and transportation efficiency.

-

Strong Adaptability

These balers can handle various types of straw, including wheat straw, rice straw, corn stalks, hay, and other agricultural residues, even with varying moisture content.

-

Easy Integration

Fully automatic horizontal balers can be seamlessly integrated into complete straw processing lines, including shredders, conveyors, dryers, and storage systems.

Main Applications of Straw Horizontal Balers

-

Biomass Power Plants

Baled straw is a key fuel source for biomass power generation. High-density bales ensure stable feeding and efficient combustion.

-

Livestock and Poultry Farming

Straw bales are widely used as animal bedding, offering good absorption and comfort while simplifying handling and storage.

-

Agricultural Waste Recycling Centres

Recycling facilities rely on horizontal balers to manage large volumes of agricultural residues efficiently and economically.

-

Paper and Pulp Industry

Certain types of straw can be used as raw materials in paper production, where consistent bale quality is essential.

-

Export and Long-Distance Transportation

For international trade or long-distance logistics, compact straw bales significantly reduce freight costs and improve container utilization.

Technical Features to Look For

-

Robust Hydraulic System

A high-quality hydraulic system ensures stable pressure, long service life, and reliable performance under continuous operation.

-

Intelligent PLC Control

Modern horizontal balers are equipped with PLC control systems and touch-screen interfaces, allowing operators to adjust bale size, pressure, and tying parameters easily.

-

Automatic Lubrication System

Automatic lubrication reduces wear on key components, minimizes maintenance requirements, and extends machine lifespan.

-

Durable Wear Parts

Compression chambers, rams, and guide rails should be made of high-strength, wear-resistant steel to handle abrasive straw materials.

-

Safety Protection

Emergency stop buttons, overload protection, and safety interlocks are essential to ensure safe operation in industrial environments.

How to Choose the Right Fully Automatic Horizontal Baler for Straw?

-

Evaluate Processing Capacity

Choose a baler with a capacity that matches your daily straw output. Oversized or undersized machines can lead to inefficiencies and unnecessary costs.

-

Consider Bale Size and Weight

Different applications require different bale dimensions and weights. Ensure the baler can produce bales suitable for your storage and transportation needs.

-

Check Power Requirements

Fully automatic horizontal balers are typically powered by electric motors and hydraulic systems. Verify that your facility can support the required power supply.

-

Assess Automation Level

Look for features such as automatic tying, bale length control, and fault diagnostics to maximize operational efficiency.

-

Manufacturer Experience and Support

Select a manufacturer with proven experience in baler production, reliable after-sales service, and readily available spare parts.

Maintenance and Operation Tips

Regular maintenance is essential to ensure long-term performance and minimise downtime:

- Inspect hydraulic oil levels and replace oil according to manufacturer recommendations.

- Check wear parts regularly and replace them when necessary.

- Keep the feeding system clean to prevent blockages.

- Train operators properly to avoid misuse and improve safety.

Future Trends in Straw Baling Technology

As agricultural mechanisation and environmental regulations continue to advance, fully automatic horizontal balers for straw are evolving toward higher efficiency, smarter control systems, and lower energy consumption. Integration with IoT technology, remote monitoring, and data-driven maintenance will further improve operational reliability and cost-effectiveness.

In addition, customized baling solutions tailored to specific straw types and regional requirements are becoming increasingly popular, helping users maximize return on investment.

Conclusion

The fully automatic horizontal baler for straw is a vital solution for modern agricultural waste management and biomass recycling. By offering high efficiency, consistent bale quality, reduced labor costs, and excellent adaptability, these machines help businesses turn straw waste into valuable resources.

For farms, recycling centers, and biomass energy projects aiming to improve sustainability and operational efficiency, investing in a reliable fully automatic horizontal baler is a strategic decision that delivers long-term benefits. With the right equipment and proper operation, straw baling can become a profitable and environmentally responsible part of the agricultural value chain.

-200x45.png)