In waste paper recycling, textile processing, or any other workshop that handles large quantities of loose materials, balers are undoubtedly a valuable asset for improving efficiency and saving space. However, when deciding to invest in a baler, the first and most crucial decision often arises: vertical or horizontal baler? This isn’t just a cosmetic difference; it’s like choosing two employees with distinct personalities for your business. One is a “powerful worker” with a small footprint and flexible operation; the other is a highly automated, powerful “assembly line giant.” So, how do you make the right choice? Don’t worry! This article will clearly break down the core differences between vertical and horizontal balers, helping you understand their essence and find the most suitable baling solution for your business.

I. Appearance and Structure

1. Vertical Hydraulic Baler:

Compact in appearance, typically upright, tall, and with a relatively small footprint.

It generally consists of a feed inlet, compression chamber, hydraulic system, and electrical control system. The feed inlet is located on the top or side of the machine.

2. Horizontal Hydraulic Baler:

Larger in appearance, typically horizontally positioned, long, relatively low, and with a larger footprint.

It primarily consists of a feed conveyor, compression chamber, hydraulic system, electrical control system, and discharge mechanism. The feed inlet is typically located at one end of the machine.

II. Working Method

1. Vertical Baler:

Material is fed into the top or side feed inlet and falls into the compression chamber by gravity.

During the compression process, the material is compressed vertically, with the compression force generated by the hydraulic system.

After baling, the bales are ejected from the bottom or side of the machine.

2. Horizontal Baler:

Material is transported into the compression chamber via a feed conveyor, and the feeding process is relatively continuous and smooth. During the compression process, the material is compressed horizontally, with the compression force generated by the horizontal pressure provided by the hydraulic system. After baling, the bales are ejected from the discharge port at one end of the equipment and can be transported via conveyor belts and other equipment.

III. Advantage Comparison

1. Vertical Hydraulic Baler – Small Footprint

Vertical hydraulic balers, with their compact design, offer significant advantages in terms of floor space. They are an ideal choice for factories or workshops with limited space. Their small footprint not only saves valuable production space but also improves space utilization, creating more possibilities for production and development.

The small footprint of a vertical hydraulic baler does not diminish its baling capabilities. On the contrary, it offers the same powerful baling capabilities, capable of meeting the needs of a wide range of items. Its efficient hydraulic system and precise control system enable a fast and stable baling process, ensuring consistent and reliable baling results.

Vertical hydraulic balers are also easy to operate and maintain. Their intuitive user interface makes them easy to use, reducing operational complexity and labor costs. Furthermore, maintenance is relatively simple, reducing both maintenance and time costs for businesses.

2. Horizontal Hydraulic Balers – High Degree of Automation

Compared to vertical hydraulic balers, horizontal balers offer a superior degree of automation. Utilizing advanced automation technology, horizontal balers achieve fully automated operation, from feeding, compression, baling, to discharging, significantly improving production efficiency and baling quality.

The high degree of automation of horizontal balers not only reduces the difficulty and intensity of manual operation but also mitigates the impact of human factors on baling quality. Through precise control systems and sensor technology, they enable real-time monitoring and adjustment of the baling process, ensuring stable and reliable baling results.

Furthermore, horizontal balers feature fast baling speed, high baling efficiency, and strong adaptability. Their high baling speed and efficiency meet the needs of large-scale production, while their adaptability also enables them to handle a wide range of baling needs.

IV. Scope of Application

1. Vertical Balers:

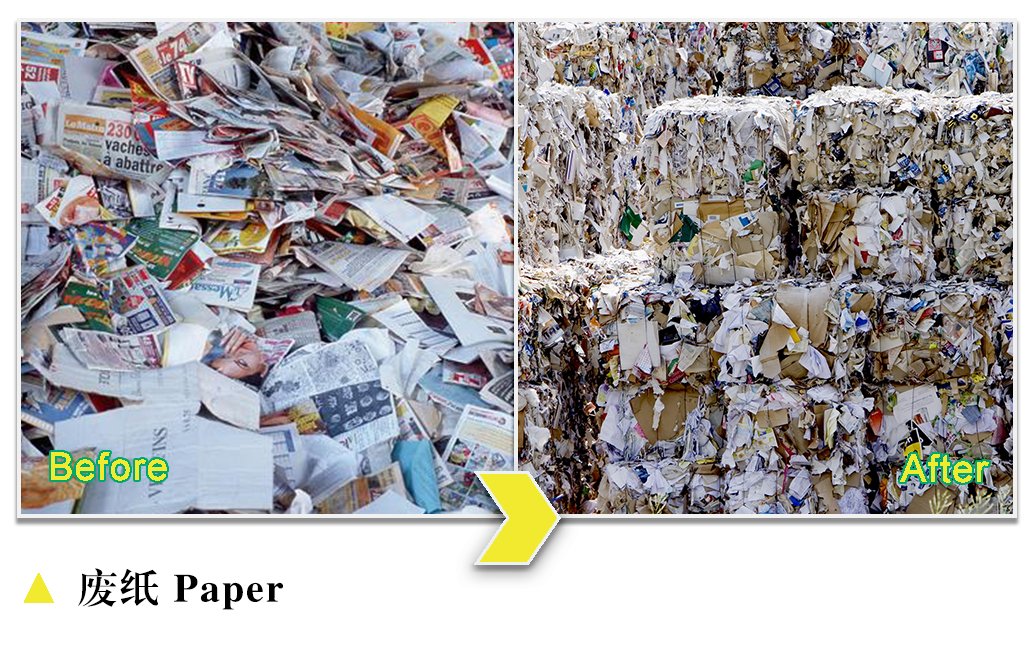

Suitable for applications with smaller processing volumes and limited space, such as small waste recycling stations, supermarkets, and convenience stores. It has a good compression effect on loose materials such as waste paper and plastic film.

Due to its high height, it is relatively easy to operate and maintain, but it does require a certain height for the plant.

2. Horizontal Baler:

It is suitable for applications with large processing volumes and ample space, such as large waste recycling stations, paper mills, and printing plants.

It has good processing capacity for large, irregularly shaped materials such as used furniture and metal products.

The feed conveyor design makes feeding more convenient and efficient, improving work efficiency. However, the equipment cost and maintenance difficulty are relatively high.

V. Performance Characteristics

1. Vertical Hydraulic Baler:

The compression force is relatively low, generally ranging from tens of tons to over a hundred tons.

The baling speed is relatively slow, and the number of bales per minute is relatively low.

The equipment price is relatively low, and the investment cost is relatively low.

2. Horizontal Baler:

The compression force is relatively high, generally ranging from over a hundred tons to several hundred tons.

The baling speed is relatively fast, and the number of bales per minute is relatively high. The equipment is relatively expensive, resulting in significant investment costs.

Conclusion

In summary, vertical and horizontal balers each have their own advantages. Companies should choose the baler model that best suits their production needs and circumstances. Both vertical and horizontal balers are crucial tools for improving production efficiency and reducing costs. In the future, with continued technological advancement and innovation, hydraulic balers will become increasingly intelligent, efficient, and environmentally friendly, bringing both opportunities and challenges to companies’ production and development.

-200x45.png)