Driven by factors such as tightening global copper supply and concerns over potential US tariffs, copper prices on the London Metal Exchange (LME) briefly touched a record high of $11,540 per ton on December 3rd, local time, with international copper prices continuing to reach new historical highs.

Industry insiders say this surge in copper prices is influenced by multiple factors. Firstly, tightening global copper supply is driving up prices. Following a mine collapse in Chile, global mining and commodities giant Glencore recently announced a reduction in its copper production for this year to 850,000 to 875,000 tons, nearly 40% less than in 2018. The company also lowered its copper production forecast for 2026. Secondly, the market widely anticipates that the Trump administration may impose tariffs on copper next year. Analysts suggest that to avoid these tariffs, large quantities of metals, including copper, are being shipped to the United States, potentially leading to critically low global copper inventory levels. Finally, strong global demand for copper resources, such as the explosive growth in demand driven by upgrades to power grids and electricity infrastructure, is also contributing to the rise in copper prices.

This is why more businesses are now investing in copper scrap shredders — specialized machines designed to process various types of copper waste into uniform, high-value recycled material. These shredders help companies reduce raw material costs, improve processing efficiency, and maximize revenue from copper scrap sales.

How Copper Scrap Recycling Reduces Costs

Copper is one of the few metals that can be recycled repeatedly without losing quality. Processing copper scrap is far cheaper than purchasing new copper, making it a highly economical option.

However, copper scrap often comes in complex forms:

- Mixed copper wires

- Copper cables with insulation

- Copper pipes

- Automotive radiators

- Electronic waste components

- Electrical motors

These materials typically require pre-processing before being sold or fed into downstream separation systems.

This is where copper scrap shredders become essential.

How Copper Scrap Shredders Help Businesses Save Costs

A copper scrap shredder is a machine designed to break down various copper-containing materials into smaller, manageable pieces. This reduces handling difficulty, improves purity, and increases the market value of the recycled copper.

Here’s how investing in a shredder helps businesses lower raw material costs and increase profits.

1. Maximizes the Value of Scrap Copper

Unprocessed copper scrap often sells at a lower price due to impurities, insulation, or irregular shapes. Shredding copper into uniform pieces increases:

- Purity level

- Meltability

- Separation efficiency

- Market selling price

Many recyclers report a 15–30% price increase simply by pre-shredding their copper before resale.

2. Reduces Labor and Manual Cutting Time

Without a shredder, processing copper scrap requires:

- Manual cutting

- Sorting

- Stripping

- Breaking large pieces

This is time-consuming and inconsistent.

A copper scrap shredder allows operators to feed material continuously, reducing labor and speeding up operations.

3. Improves Efficiency of Downstream Machines

Shredded copper is easier to process in:

- Granulators

- Separators

- Cable recycling lines

- Smelting furnaces

By producing uniform particle sizes, shredders enhance the performance of the entire recycling system.

4. Reduces Transportation and Storage Costs

Shredding copper significantly reduces volume.

Lower volume = fewer storage requirements + lower transport fees.

For scrap yards exporting copper, this can mean huge savings on container shipping costs.

5. Ensures Safer Handling and Cleaner Workplaces

Large copper pipes, wires, or radiators can be dangerous to cut manually.

Shredding provides:

- Safer workflows

- Less physical strain

- No sparks compared with manual cutting

- Cleaner material output

Businesses can meet workplace safety standards more easily.

Which Copper Scrap Shredder Do You Need?

Depending on the material type, businesses typically choose from three main shredding solutions:

1. Single Shaft Shredder

Ideal for:

- Copper wires

- Soft copper materials

- Cable insulation

- Coiled scrap

Provides controlled particle size and high precision.

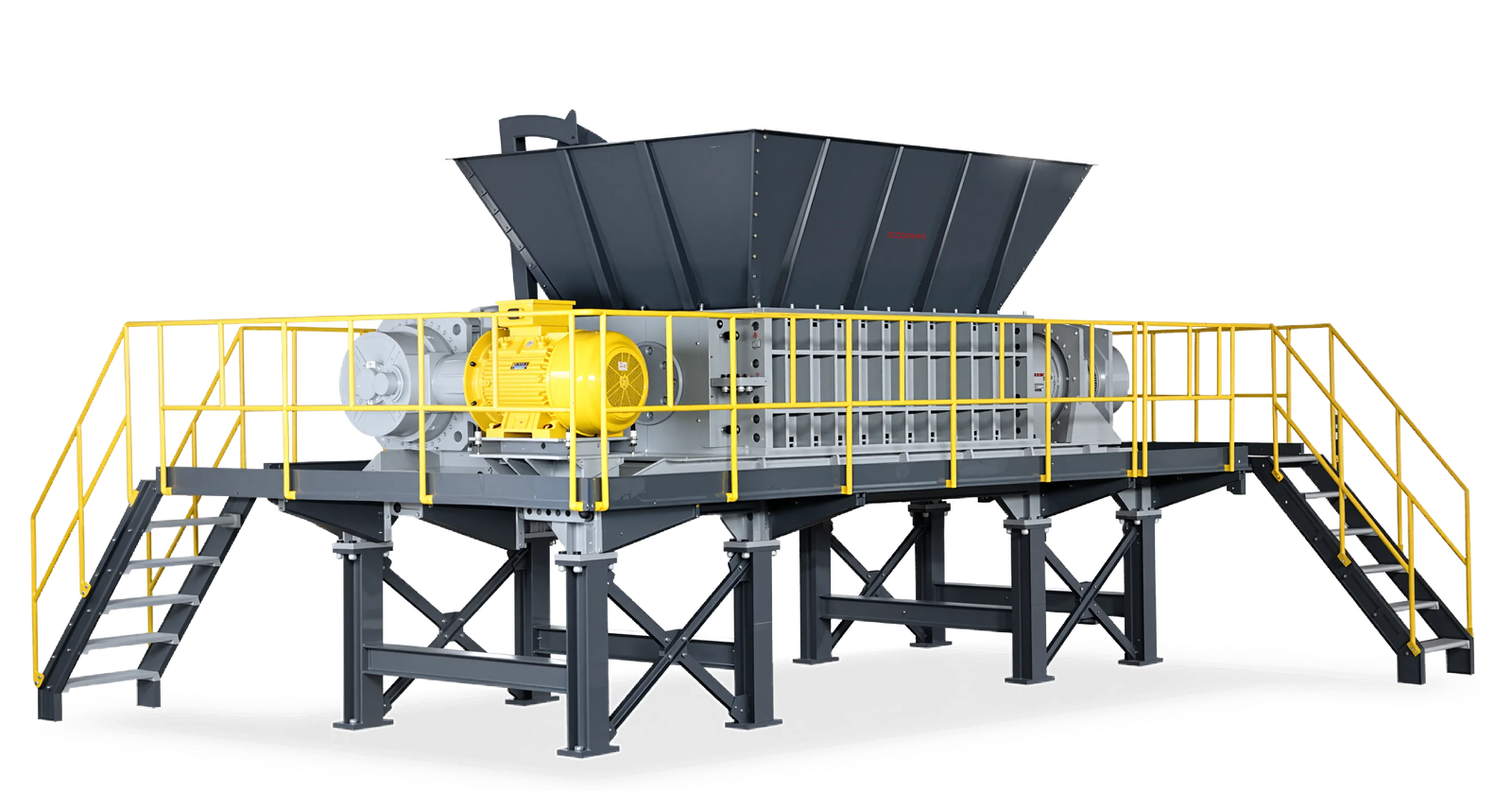

2. Double Shaft Shredder

Best for:

- Thick copper pipes

- Bulky scrap

- Radiators

- Heavy industrial copper waste

Known for high torque and strong cutting force.

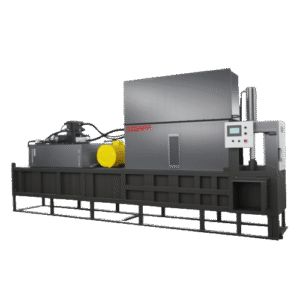

3. Heavy-Duty Crusher

Suitable for:

- Large volumes

- Mixed metal scrap

- High-capacity processing

For plants requiring continuous production.

Why Businesses Choose Our Copper Scrap Shredders

Our shredders are designed specifically for the recycling industry and offer:

✓ High-torque industrial motors

✓ Wear-resistant alloy blades

✓ Stable performance for 24/7 operation

✓ Customizable capacity and discharge sizes

✓ Low maintenance cost

✓ Strong structure for long-term durability

We support customers with:

- Free material testing

- Custom solutions based on scrap type

- Technical data sheets

- Installation support

- After-sales service

Whether you’re a scrap yard, recycling plant, or metal processing factory, we can help you choose the right machine for your needs.

Conclusion: Rising Copper Prices Make Shredding More Valuable Than Ever

With copper prices continuing to rise globally, companies that rely on copper materials must find smart ways to reduce costs and improve efficiency. Investing in a copper scrap shredder allows businesses to:

✔ Lower raw material expenses

✔ Increase resale value of scrap

✔ Improve downstream processing

✔ Reduce labor and logistics costs

✔ Strengthen competitiveness in a volatile market

In the current copper market environment, shredding is no longer optional — it’s a strategic advantage.

If you need technical specifications or a quotation for a copper scrap shredder, feel free to contact us.

📩 info@gigapa.com

We’re ready to help your business save more and recycle better.

-200x45.png)