As global industrialization and urban development accelerate, the volume of solid waste has reached unprecedented levels. According to the World Bank, the world generates over 2 billion tonnes of municipal solid waste annually, and this number is expected to grow to 3.4 billion tonnes by 2050. Managing this waste efficiently is not only a matter of environmental protection but also a crucial step toward resource recovery and recycling.

Solid waste treatment systems rely on specialized equipment designed to reduce, separate, compact, and recycle waste materials. This article explores the main machinery used in modern waste management facilities, with a focus on shredders and balers — the core equipment for industrial recycling operations.

Why Solid Waste Treatment Equipment Matters

Before waste can be recycled or disposed of safely, it must be:

✔ Reduced in size

✔ Sorted and separated

✔ Dehydrated or compacted

✔ Transported efficiently

✔ Reprocessed into reusable material

These tasks require industrial-scale solutions, especially when dealing with metals, plastics, paper, and municipal solid waste.

Shredders — The First Step in Waste Size Reduction

Shredders play a vital role in breaking down bulky waste into smaller, manageable pieces. They enhance the efficiency of downstream recycling processes, including sorting, washing, and baling.

Mainly used for: metal waste, plastic, wood, tires, electronic waste, etc.

🔹 Single Shaft Shredder

A single shaft shredder is ideal for processing:

- PP/PE plastic films

- ABS/HDPE plastic blocks

- Wood waste and pallets

- Textile waste

- Light metal scrap

✅ Features:

- One rotor with sharp cutters

- Hydraulic pusher ensures continuous feeding

- Granular and uniform output size

- Great for recycling lines that require accurate size control

📌 Best for factories requiring high-precision shredding.

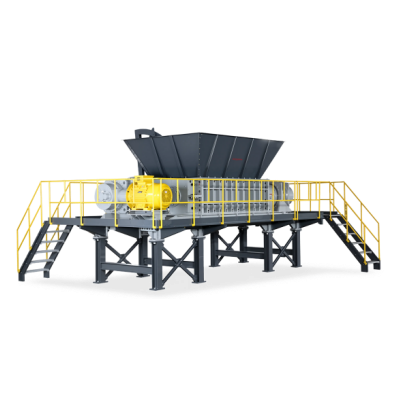

🔸 Double Shaft Shredder

A double shaft shredder is designed for:

- Waste household appliances

- Aluminum and iron scrap

- Wheels, tires, and rubber waste

- Copper, steel, scrap motors

- Municipal solid waste (MSW)

✅ Features:

- Two rotating shafts working together to tear waste apart

- High torque and low-speed crushing

- Strong resistance to hard and tangled materials

📌 Preferred for high-volume, heavy-duty industrial recycling and pre-shredding.

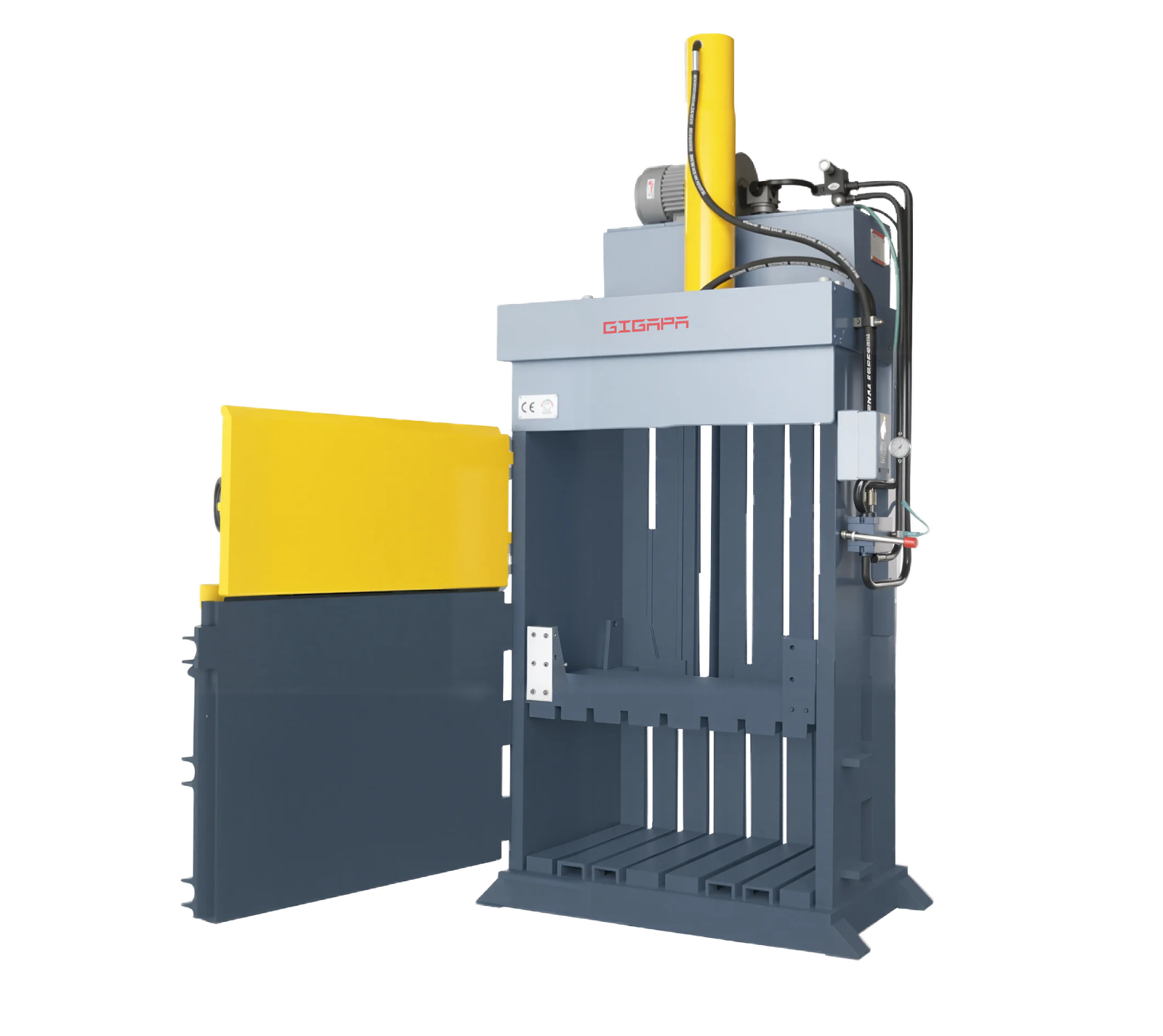

Baling Machines — Compressing Waste for Transport & Storage

Once shredded or sorted, waste must be compacted to reduce volume and logistics cost. Baling machines (also known as balers) compress recyclable waste into dense blocks.

Balers are widely used for:

- Scrap metal recycling

- Waste paper and cardboard

- PET bottles and plastic films

- Textiles and agricultural waste

There are several types:

| Type | Application | Automation Level |

|---|---|---|

| Vertical Balers | Small recycling centers, carton & film | Manual / Automatic |

| Horizontal Balers | Plastic & paper recycling plants | Semi / Fully Automatic |

| Metal Baling Machines | Steel, aluminum scrap | Heavy-duty |

| Bagging Balers | Loose materials like straw or sawdust | Bag-wrapped compression |

| Briquetting Press Machines | Metal chips, aluminum shavings, steel swarf | Fully Automatic / Hydraulic |

✅ Benefits:

- Reduce waste volume by up to 90%

- Easier storage, stacking, and transportation

- Increase material resale value

📌 Essential for waste factories to improve logistics efficiency.

Crushers and Granulators

Sometimes shredding is not enough. Fine size reduction is needed for:

- Plastic pelletizing

- RDF fuel production

- Wood biomass processing

Crushers and granulators help achieve smaller particle sizes for further recycling or combustion systems.

Drum Screens and Sorting Equipment

After shredding, materials must be separated based on size, density, or magnetic properties:

- Trommel screen (drum screen) for size classification

- Magnetic separator removes iron scrap

- Eddy current separator extracts non-ferrous metals

- Optical sorters identify plastics by resin type

These systems ensure clean and high-value recycling output.

Conveying Systems — Keeping Production Flowing Smoothly

Every waste treatment line relies on conveyor belts to:

- Transport shredded materials

- Feed balers or crushers

- Improve automation efficiency

- Reduce manual handling and labor costs

Modern facilities integrate automated conveyor systems for continuous operation.

How These Machines Work Together

A typical solid waste recycling line:

1️⃣ Pre-shredding with double shaft shredder

2️⃣ Fine shredding or crushing with single shaft shredder / crusher

3️⃣ Sorting and metal separation

4️⃣ Volume reduction using baling machines

5️⃣ Storage or direct sale to recyclers

This combination transforms waste into valuable recyclable resources.

GIGAPA — Reliable Equipment for Solid Waste Treatment

If you are searching for high-performance machinery for your waste recycling business, GIGAPA provides:

✅ Single Shaft Shredders

✅ Double Shaft Shredders

✅ Metal / Plastic / Paper Balers

✅ Complete Waste Recycling Systems

✅ Customized Design for Industry Needs

Industries We Serve:

✔ Scrap metal yards

✔ Plastic recycling plants

✔ Municipal waste treatment facilities

✔ Packaging and logistics warehouses

✔ Wood processing factories

📩 Contact us to upgrade your waste recycling efficiency today!

Final Thoughts

Solid waste treatment plays a major role in sustainability, resource recovery, and economic development. With the right shredders, balers, and sorting equipment, waste is no longer a burden — it becomes a valuable resource.

To support a cleaner and greener future, modern industries must adopt advanced waste processing technologies and automated recycling solutions.

-200x45.png)