With the increasing demand for resource recycling and environmental protection, the performance and efficiency of metal briquetting press, as the core equipment for scrap metal processing, directly affect the company’s operating costs and market competitiveness. With the iteration of technology and the upgrading of industry standards, customers’ requirements for equipment are no longer limited to simple compression functions, but pay more attention to intelligence, energy saving and long-term stable return rate. So, which type of metal briquetting press can win more market recognition?

The following types of metal briquetting press are more popular in the market:

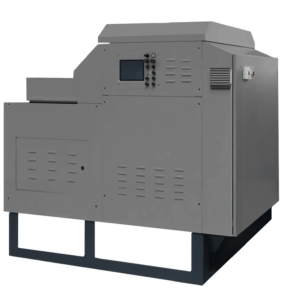

1. Fully automatic metal briquetting press:

- Highly automated operation: GIGAPA briquetting press has been deeply involved in the market for more than ten years. It adopts advanced PLC control system, which can automatically complete a series of work processes such as feeding, compression, pressure holding, and discharging of metal materials, greatly reducing manual intervention, improving production efficiency, and reducing labor intensity. It is suitable for large-scale and efficient metal waste processing sites.

- Precise control performance: Equipped with high-precision sensors, it can monitor and accurately control parameters such as pressure and displacement during the compression process in real time, ensuring the dimensional accuracy and density consistency of each metal package, and improving the recovery rate and reuse value of metals.

- Fault diagnosis and early warning function: Built-in intelligent fault diagnosis system can quickly detect and display equipment fault information, which is convenient for maintenance personnel to locate and troubleshoot faults in time and reduce equipment downtime. At the same time, remote monitoring and early warning can also be realized, which is convenient for managers to grasp the equipment operation status in real time.

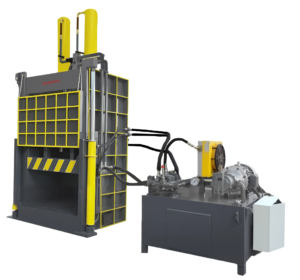

2. Hydraulic metal briquetting press:

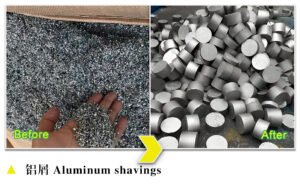

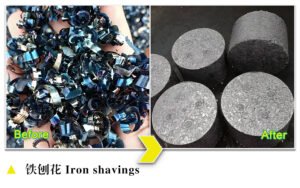

- Powerful compression force: The heavy metal briquetting press provides a strong and stable compression force through the hydraulic system, which can compress various metal wastes, such as scrap iron, scrap steel, scrap copper, scrap aluminum, etc., as well as metal chips, shavings, etc. into high-density blocks, effectively reducing the volume of waste materials, facilitating storage and transportation, and reducing transportation costs.

- Reliable working performance: The hydraulic system uses high-quality hydraulic components, such as high-performance hydraulic pumps, hydraulic cylinders and wear-resistant oil seals, etc., to ensure that the equipment runs smoothly, is durable, and has strong continuous working capacity, which can meet the needs of long-term and high-intensity production.

- Customizable mold: Equipped with briquetting molds that can be customized according to different metal materials and user needs, it can compress metal into blocks of various shapes and sizes, such as rectangles, cylinders, octagons, etc., to meet the special requirements of different users and improve the versatility and adaptability of the equipment.

3. Horizontal metal briquetting press:

- Large processing capacity: Heavy metal briquetting press is a brand product, usually with a larger material box size, which can accommodate more metal waste. The weight of the compressed blocks is large, which is suitable for processing a large amount of scrap metal, such as scrap car shells, large metal components, etc., which improves the processing efficiency and reduces the unit processing cost.

- Flexible discharging method: There are various discharging methods, such as side-turning bags and side-pushing bags. You can choose the appropriate discharging method according to the user’s site layout and production needs, which is convenient for the removal and handling of the blocks.

- Compact structure and high stability: The overall structural design is reasonable, the body is solid, and the stability is good. During the compression process, it can effectively ensure the balance and stability of the equipment, reduce vibration and noise, and extend the service life of the equipment.

4. Vertical metal briquetting press:

- Suitable for small and medium-sized waste processing: The appearance is vertical, and the floor space is relatively small. It is suitable for processing small and medium-sized scrap metals, such as waste copper wire, waste aluminum wire, metal shavings, scraps, etc. It can also have a good compression effect on some thin metal wastes, and can be flexibly placed in different workplaces.

- Convenient loading operation: The silo is located above, which is convenient for manual or mechanical loading. The operation is simple and convenient, which can effectively improve work efficiency and reduce labor intensity.

- High-precision compression molding: The hydraulic cylinder drives the packing head to gradually compress the metal waste, which can achieve high-precision compression molding, making the bales more compact and regular, and improving the recycling value of the metal.

5. Multifunctional metal briquetting press:

- Wide material adaptability: This type of briquetting machine can handle various types of metal waste, including metal materials of different materials, shapes and sizes, such as cans, paint buckets, iron cans, bicycles, motorcycles, cars and other scrap metals can be packaged and processed, meeting the diverse needs of different users.

- Multiple function integration: In addition to the basic compression function, it may also integrate multiple functions such as automatic weighing, automatic bundling, and waste recycling, realizing the integrated operation of metal waste processing and improving the added value and comprehensive benefits of the equipment.

- Energy saving and environmental protection: Energy saving and environmental protection factors are fully considered in the design and manufacturing process, and advanced energy-saving technologies and environmental protection measures are adopted, such as optimizing the energy consumption of the hydraulic system and equipping waste recycling devices, which reduces the energy consumption and pollutant emissions of the equipment and meets the requirements of modern society for environmental protection.

With the rapid development of the resource recycling industry, efficient, intelligent and energy-saving metal briquetting machines are becoming the mainstream choice of the market. From fully automatic control to multi-functional integration, from large-tonnage hydraulic compression to flexible miniaturized design, different types of equipment meet the diverse needs of scrap metal processing. Among them, automated, highly stable, energy-saving and environmentally friendly equipment are particularly favored by customers because they can not only improve production efficiency, but also reduce operating costs and bring higher returns on investment.

As an industry-leading brand, GIGAPA metal briquetting press provides customers with high-performance and high-reliability solutions with more than ten years of technical accumulation and market verification. Our equipment uses advanced PLC control systems, high-precision hydraulic components and intelligent fault diagnosis technology to ensure stable and efficient operation performance. Whether it is a large scrap steel processing plant or a small and medium-sized metal recycling company, GIGAPA can provide customized briquetting solutions to help customers optimize production processes and increase the value of metal recycling.

-200x45.png)